(Note – SBH – I have found it difficult to differentiate between different brick and tile works in Prestongrange with regards researched information. It may be that some references below relate to the Old Kirk or Ravenscroft Brick and Tile Works or indeed other separate locations. If anyone can clarify then please get in touch)

Canmore

Info

East Lothian Bank – Robert Gordon was a founding member of the East Lothian Bank.

The main potteries in the East Lothian area in the nineteenth century were that of William Cadell & Company, West Pans, R. & G. Gordon and Belfield & Company. These are all sited along the coastline between Prestonpans and Musselburgh.

In 1772, George Gordon began pottery production at Morrison’s Haven. In 1774, Gordon personally moved into the pottery with his two sons, George (Junior) and Robert – the latter being the writer of this letter.

Gordon’s took over Bankfoot, in 1795, and in the early nineteenth century produced a wide variety of good quality domestic earthenware.

After suffering substantial losses on the collapse of the East Lothian Bank, in 1822, Gordon’s went into decline.

When the owner of Prestongrange estate began consolidating his lands, he accused Gordon’s of neglecting buildings, wrongly claiming land, and taking clay intended for bricks and planning a pottery without permission. Litigation concluded, in 1836, with Gordon’s removal from Morison’s Haven although Gordon’s continued at Rope Walk, Kirk Street and Bankfoot until sequestration in 1842.

Brick manufacture – did not develop early in Scotland, where there were ample supplies of stone. However, tiles were worked from medieval times, especially for the decoration of religious houses. By the late 18th century, brickmaking for house building was on the rise, as was an interest in the hand manufacture of earthenware tiles and pipes for field drainage, especially in places where a suitable supply of clay existed. This was the case along the coastline from Portobello to Prestonpans. Once waste fireclay and shale (‘blaes’) from coal mining were recognised as having suitable properties for use in pottery and brick manufacture, production was closely linked to the source of these raw materials, as was the case at Prestonpans. At Prestongrange, an interest in agricultural improvement encouraged the manufacture of field drainage tiles which, in turn, led to the manufacture of heavy ceramics. In 1789, two sites produced tiles and bricks, one near the Old Kirk and another, using clay dug locally, at Ravenscroft.

By 1874 Prestongrange colliery and brickworks were owned by the Prestongrange Coal and Iron Company and it was during this period that the tileworks developed from a rural supplier of estate tiles to a major manufacturer of heavy ceramics, with a significantly increased workforce. Despite various changes in management, census records reveal that workmen were continuously employed in the output of a range of machine and hand made bricks and salt-glazed wares, such as floor and roofing tiles, speciality bricks and furnace fittings, garden wares, pipes for water, gas and sewage and sanitary wares such as sinks and toilets. By the 1890s, the brickwork occupied a large area of the Prestongrange site, with large moulding halls and a variety of bottle and down draught kilns. From 1895, under the Summerlee Company, the brickwork continued to expand. New kilns were built for glazed pipe production. Bottle kilns were replaced by new downdraught kilns, which survived well into the 20th century and in 1910, a Hoffman continuous kiln was built. This was replaced in 1937 by the Hoffman kiln which still stands today, as does the chimney of the original kiln. Prestongrange Colliery continued to supply raw materials for the brickworks until its closure in the early 1960s. The increased cost of transporting raw materials and fuel to the site was a major factor in the gradual decline of the brickworks, which finally closed in 1975.

Below – 1799 – William Forrest’s map of 1799 shows that by this date Prestongrange was expanding as an industrial complex. His map depicts not only the haven but also a mill and pottery. A star-shaped symbol is also depicted. Whether or not this marks the relative position of a fort is difficult to interpret. The 1822 map by Thompson depicts ‘Morrison’s Haven’ and a ‘flint mill’. Unlike the 1773 Armstrong map, only a single curving pier is shown. It may be the case that only one of the piers survived at this time. An 1832 plan of ‘Mr Gordon’s Property’ by Grant Suttie shows the position of a pottery with three kilns and part of Morrison’s Haven. Part of the ‘remains of an old fort’ are also depicted.

A coloured mine engineering plan of 1877 shows the underground coal seams being worked at Prestongrange Colliery in that year. The plan is very useful as it depicts the brick and tile works with a set of nine beehive kilns situated around a rectangular machine shop. At the harbour, the northern pier is shown along with a coal-loading pier. The southern harbour breakwater is not shown and may have been out of use at this date.

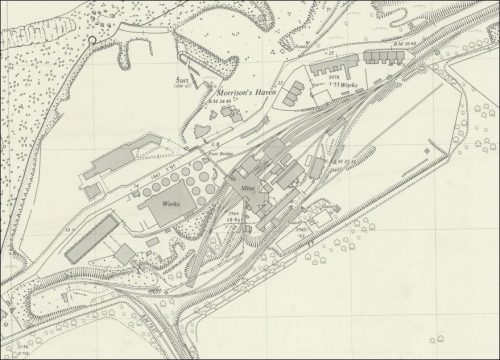

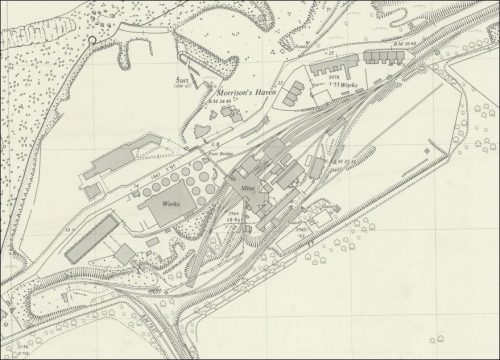

The 1894 Second Edition Ordnance Survey map (Fig. 4) shows that Prestongrange had undergone dramatic industrial expansion since 1854. The old brick and tiles works had been cleared to be replaced by a larger brick and tile company operating under the title of the Prestongrange Brick and Fire Clay Works. Situated around a large rectangular building are thirteen circular beehive kilns and a large brick kiln and chimney. Prestongrange Colliery is depicted for the first time to the east of the brickworks. The main shaft and pit-head buildings are shown along with several other unnamed buildings. A large rectangular railway shed was present on the south side of the pit-head. A railway ran southwards towards Morrison’s haven Junction which provided a direct link to a loading pier at Morrison’s Haven, where coal was loaded directly onto boats for export. All of the colliery waste was being dumped to the east of Morrisons’s Haven. The map clearly shows a railway line on top of a tip, two earlier tips and lines are shown adjacent.

The 1907 Third Edition map (Fig 5) shows that Prestongrange had expanded again with the most significant development since 1894 being that of mineral transportation. The railway system leading to Morrison’s Haven had been developed significantly with a hauling tramway leading directly from the brick and tile works to the haven. Several new branch lines and sidings had been built along with new lines to the tips, both near the colliery and east of the haven. Here the configuration of the shoreline was significantly altered by the amount of colliery waste that had been dumped in the intervening period between when the two map surveys. This expansion in the works also led to the requirement for workers housing. Two miners’ rows were built at the northeast end of the colliery boundary. These appear to have been two-storey dwellings with accommodation for up to 22 families. The upper floors were entered by a back stair on the south side of the buildings.

Scotland places – A succession of local landowners and lease holding families ran Prestongrange’s industries. Among them in the nineteenth century the Gordons and the Grant-Sutties. Each owner or Company invested in new ideas, buildings and equipment to try and exploit the area’s full potential. For example, at the beginning of the last century, the Summerlee Company replaced the kilns with new designs according to the demands for bricks or glazed pipes. It was under Summerlee that the brickworks had its greatest period of production. National Coal Board were owners and ultimately the Scottish Brick Corporation.

The Hoffman kiln – It is called a Hoffman Continuous Kiln, originally a German design, but this kiln is a variant designed by Cleghorn and built in 1937. At their peak, these vast chambers baked thirty thousand bricks at one firing.

There are twenty-four open chambers here. The raw clay bricks would be placed in each. Once the kiln entrances and chamber divisions had been bricked up and sealed with clay paste, the firing would begin. During the firing, coal was added through vents in the roof. A firing lasted fifty hours or more. The brickworks was one of the most successful operations at Prestongrange and outlasted the pit by more than a decade. The works continued by importing clay and coal right up to the 1970s

21/01/1729 – Caledonian Mercury – At the style works in Prestonpans, there is to be sold, the best pantyles made in this Kingdom for 50 shillings sterling per 1000, on 6 months security given. And for encouragement to the buyer, for 45 shillings per 1000, ready money. Or on demand, several other sorts of styles and bricks of all sizes at reasonable prices.

Below – 05/08/1729 – Caledonian Mercury – There is to be sold, as formerly, at the Brick and Tile Work Manufactory in Prestonpans, all sorts of good sufficient pantiles as also all Scots and sizes of bricks, pavements, chimney-backs, at very easy and reasonable rates.

By order of the trustees of the creditors of William Douglas of Glenbervy and Robert Douglas of Scotscraig. The roup and sale of the lands and estate of Scotscraig, Foody and Fingask, is prorogated to Tuesday the eleventh of November next, within the house of Mr Thom Vinter, Edinburgh, twixt the hours of 3 & 5 in the afternoon. The rental, progress and conditions of sale are to be seen in the hands of William Forbes, writer to the signet.

1760s – The 1985 publication ‘A survey of Scottish brickmarks’ suggests that Anthony Hillcote (Hillcoat) operated the works at some point during the 1760s.

12/08/1761 – Caledonian Mercury – Advertisements – To be set in tack, for any number of years that shall be agreed upon. The brick and tyle work at Prestonpans, with an inclosure of ten acres, from whence the clay is dug contiguous to it. Enquire for James Thompson, clerk to the work or the proprietor at his house nigh Preston. N.B The work has had for these sixty years a particular reputation for the durableness of the tyle.

Below – 27/03/1806 – Caledonian Mercury – Brick and Tile for sale. A quantity of good brick and tile for ready money. Apply to Bailie James Watt, Preston Pans or Mrs Webster’s Tilework there. (Note – SBH – I have added this article here meantime as I believe it may relate to the Prestongrange Brick and Tile Works but this will require further research)

1812 – c. 1833 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests that Robert and George Gordon operated the works during this time.

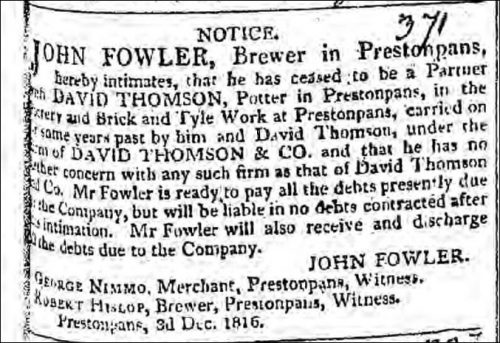

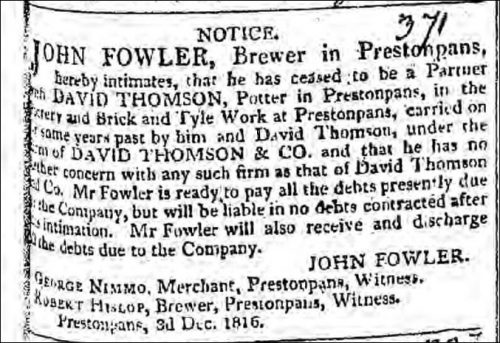

Below – 07/12/1816 – Caledonian Mercury – John Fowler, Brewer, Prestonpans has ceased to be a partner with David Thomson, Potter in Prestonpans in the Pottery, Brick and Tyle Work in Prestonpans.

1825 – 1826 – Robert and George Gordon, Earthenware manufacturers, Bankfoot, Preston Pans.

Below – 26/05/1834 – Arris’s Birmingham Gazette – Pottery and Brickwork Preston Grange to let.

1837 – Pigot and Co – Sir G. G Suttle, Brick and tile manufacturer, Preston Grange Colliery. George Leach, Clerk.

1837 – 1860 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests that Sir George Grant Suttie operated the works during this time.

08/07/1848 – The Scotsman – Prestongrange Brick and Tile Work – A constant supply of bricks and drain tiles, of the very best quality, can always be had at Preston Grange Tilework, near Prestonpans, and can be delivered at any of the Stations on the North British Railway at the shortest notice. The agents at the different stations will furnish a list of the sizes and prices, and exhibit a sample of the bricks and tiles and all farther particulars supplied by John Currie, at Preston Grange, by Prestonpans, who will receive orders for shipping bricks or tiles in Morrisonhaven, where they can be delivered free on board without the least delay. Preston Grange, 1st July 1848.

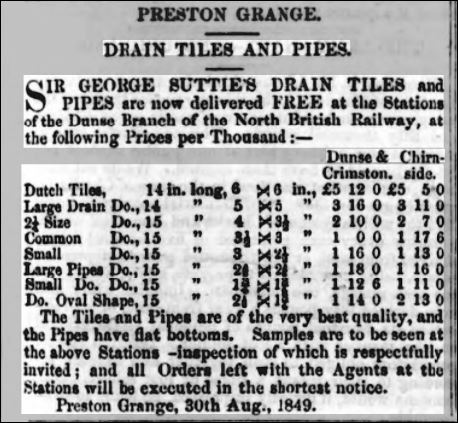

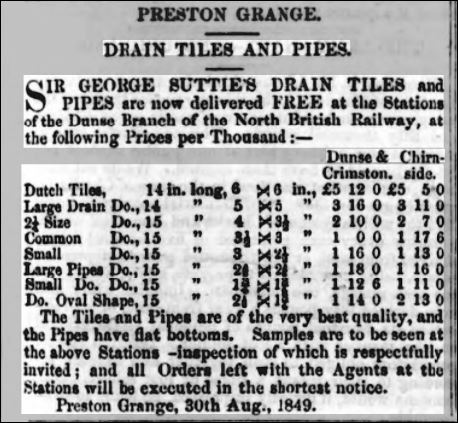

Below – 07/09/1849 – Kelso Chronicle – Sir George Sutties drain tiles and pipes now being delivered free at the Stations of the Dunse(Duns) branch of the North British Railway at the following prices per thousand.

10/08/1850 – Prestongrange brick and tile works – These draining tiles and tiles, are of all sizes, are well known to be of the very best quality, and the Pipes have flat bottoms. The bricks are well burnt, and admirably adapted for building purposes and a constant supply of them can constantly be had at Prestongrange Tilework and can be delivered to any of the Stations of the North British Railway on the shortest notice.

The Agents at Heriot, Galashiels and Hawick Stations of the Hawick branch – Chirnside, Crimstane and Dunse Stations of the Dunse Branch and at Grantshouse Station of the North British Railway will furnish a list of the sizes and prices, and exhibit of a sample of the bricks and tiles, inspection which is respectfully invited; and all farther particulars supplied by James Myles, at Prestongrange, by Prestonpans, who will also receive orders for shipping bricks and tiles at Morissonshaven where they can be delivered free on board without the least delay Prestongrange, 5th August 1850.

14/06/1851 – The Scotsman – Preston Grange brick and tiles – These draining tiles (which will consist of pipe and arch tiles) are of all sizes, and well known to be of the very best quality. The bricks are of a large size, well burnt, and admirably adapted for building purposes. The whole has been recently considerably reduced in price, and a constant supply of them can always be had at Prestongrange Tilework and can be delivered at any of the Stations of the North British Railway on the shortest notice.

All further particulars will be communicated by James Myles, at Prestongrange, by Prestonpans, who will also receive orders for shipping bricks and tiles at Morrisons Haven, where they can be delivered free on board without the least delay.

1852 – Sir George Grant Suttie, brick and tile manufacturer, Preston Grange. James Myles, manager.

Below – 1853 – Preston Grange Brick and Tile Works.

05/10/1853 – North British Agriculturist. Preston Grange bricks and tiles. A constant supply of these bricks and tiles which are of well known excellent quality can always be had at Preston Grange Tileworks and can be delivered at any of the stations of the North British Railway on the shortest notice. For further particulars apply to James Myles, at Preston Grange, by Prestonpans, who will also receive orders for shipping bricks and tiles at Morrisonshaven, where they can be delivered free on board without the least delay. 22d Sept. 1853.

27/09/1854 – North British Agriculturist. Preston Grange bricks and tiles. These draining tiles and bricks are well known to be of the very best quality, and a constant supply of them can always be had at Prestongrange Tilework and can be delivered at any of the stations of the North British Railway or free onboard ship in Morrisonshaven Harbour on the shortest notice. For further particulars, apply to James Myles at Prestongrange, by Prestonpans. Sept. 20, 1854.

Below – 1855 – Preston Grange Brick and Tile Works.

Below – 22/09/1855 – The Scotsman – Prestongrange brick and tile advert. James Myles.

1861 – John Gilbert was described as brick and tile manufacturer employing 9 men and 5 boys’ in the 1861 census. He was also associated with the site in 1841 but, although it was working, is not present in 1851.

1869 – Brick and Tile Depot – Prestongrange Fire Brick Co. Limited, 4 Scotland Street Station Roxburgh James, St. Leonard’s station.

Prestongrange Coal & Fire Brick Co. Limited, Scotland Street Station – L. Branford, agent.

01/12/1877 – Edinburgh Evening News – Subscription for £50,000 first mortgage debentures bearing interest at 5 1/2% per annum – The Prestongrange Coal and Iron Company Limited … The output of fireclay last year was 4197 tons …

03/12/1877 – Edinburgh Evening News – Subscription for £50,000 first mortgage debentures bearing interest at 5 1/2 % per annum. The Prestongrange Coal and Iron Company Limited (incorporated under the companies acts 1862 and 1867) Share capital, £250,000 in 25,000 shares of £10 each, 20,000 of which are leased and fully paid up … The very large quantity of excellent fire clay in the estate affords great facilities for the manufacture of sanitary pipes and other fire clay goods, for which the Company has a daily increasing demand … The output of fireclay last year was 4197 tons …

1878 – Prestongrange Coal and Iron Company – R.L.M.Kitto Managing Director. Thomas Brentnall Jun Secretary

Prestongrange Coal & Fire Brick Co. Limited, Scotland Street station—L. Branford, agent

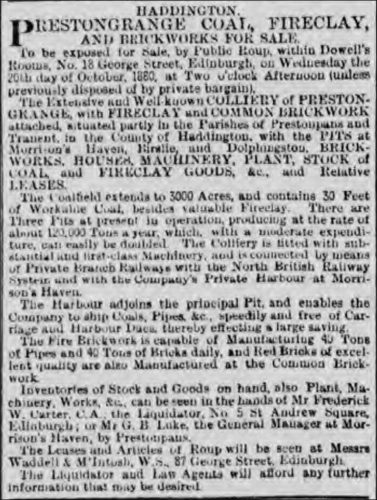

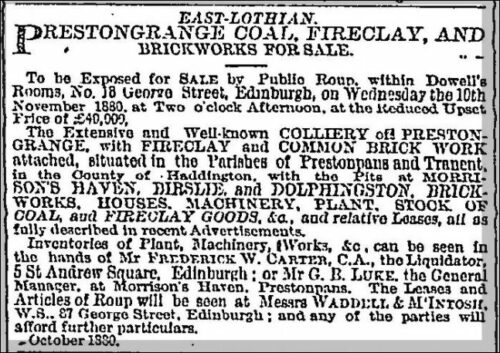

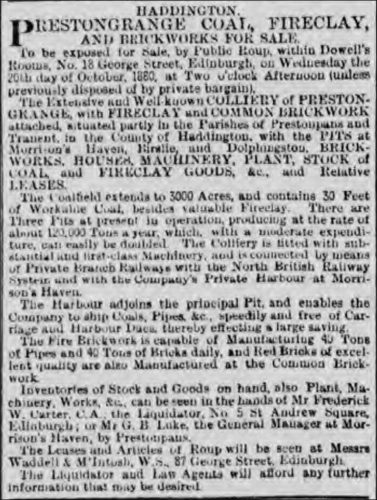

Below – 15/09/1880 – Glasgow Herald – Prestongrange Coal, Fireclay and Brickworks for sale. Mr G. B. Luke, General Manager at Morrisons Haven by Prestonpans.

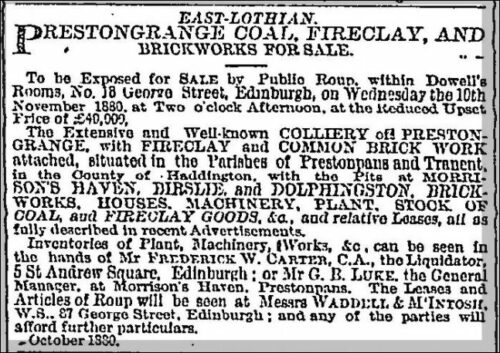

Below – 30/10/1880 – The Scotsman – Prestongrange Coal, Fireclay and Brickworks for sale. Mr G. B. Luke, General Manager at Morrisons Haven by Prestonpans. Reduced upset price of £40,000.

Below – 05/01/1881 – Glasgow Herald – Prestongrange Coal, Fireclay and Brickworks for sale. In liquidation.

09/09/1882 – Glasgow Herald – Prestongrange Coal and Iron Company Limited in liquidation. I hereby give notice that the business formerly carried on by the above company or by me as liquidator for its behoof was this day, 6th September 1882, transferred to the Prestongrange Coal and Firebrick Company Limited, who will be responsible after this date for all goods supplied to the collieries, brickworks &c on the order of their secretary and manager, Mr G. B. Luke, I having now ceased to conduct the business carried on under the liquidation. All goods supplied to the works on my order prior to this date will be paid for when due at the registered office of the new company at Morrishaven, where all accounts should be rendered. Fred W. Carter, liquidator. Edinburgh, 5 St Andrews Square. 6th September 1882.

06/10/1884 – Glasgow Herald -Unrest due to the Franchise Bill – Demonstrations at Haddington … The Prestongrange fireclay workers declared that ” the Lords have burned their fingers at the franchise kiln”…

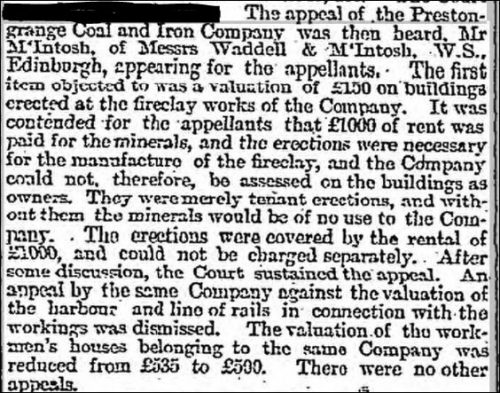

Below – 19/09/1885 – The Scotsman – Appeals against assessors valuations.

04/05/1886 – Glasgow Herald – Wanted, a practical fire brick and cover maker. A first-class man. Must be steady. Apply Prestongrange Pipe and Fire Brick Works, Prestonpans.

25/05/1886 – The Scotsman – International Exhibition – Exhibitors included The Prestongrange Coal and Fire Brick Company.

03/02/1887 – The Scotsman – The Prestongrange Coal and fire Brick Company appealed against the valuation of Morrison’s harbour, a little harbour used by the Company in connection with their mineral traffic, of which they were tenants under a lease granted by the late Sir. George, Grant. Suttie. Counsel stated that the subject was entered in the roll first at a yearly rent of £20, which was a proper entry, but the appellants appealed against another entry of the same subject where it was stated that they were the tenants and occupiers of the subject at a yearly rent of £80. Mr Dundas, who appeared for the appellants, said that the latter separate valuation had been laid upon the appellants in respect of certain improvements executed by them under the lease. The appellants had the power to use the harbour for 31 years, and power levy dues for 21 years. The assessor seemed to hold that this lease was something more than a mineral lease for 31 years, and that therefore he was bound to look behind the fixed rent, and that the power to make improvements imported a consideration other than rent. He (Mr Dundas) maintained that the right to use the harbour for 31 years was simply a natural adjunct of the mineral lease, and which was valued in the stipulated rent.

Mr Turnbull, the assessor of the County of Haddington, said that the powers granted to the parties under the lease to make alterations on the harbour were immediately carried out and the facilities accordingly greatly increased. £8000 was expended on alterations on the harbour. Their Lordships made avizandum with the case.

09/12/1887 – Haddingtonshire Courier – Action for damages abandoned. On Tuesday, Lord Lee and jury were to have tried in the Court of Session an action at the instance of John Jardine, miner, Middle Street, Cuthill, against the Prestongrange Coal and Fire Brick Company for £500 damages, but when the case was called, it was intimated that pursuer had abandoned the action. The pursuer was working in the defenders No. 2 Dolphingstone Pit in August 1886. There had been a large quantity of mineral excavated, and he and his neighbour applied to the foreman for propping but did not receive it. The next day several tons of mineral fell upon the pursuer, breaking his thigh bone and crushing him. He maintained that the defenders were at fault in not giving sufficient props and because the foreman was, as alleged, incompetent. In defence, it was stated that the pursuer was bound to prop and secure the roof of the place where he was working and that no kind of previous inspection could have revealed that the accident was likely to occur. The pursuer was found liable in expenses,—Local agents—for the defender, Ferme, Ferme and Williamson, Haddington.

Action for personal injuries. The record has been closed and issues raised in an action the instance of Charles Sutherland v The Prestongrange Coal and Fire Brick Company. The pursuer, a carter residing at Meadow Mill, sues the defenders for £500 for personal injuries. On the 12th April last, his employers, Messrs Mellis, soap manufacturers, sent him with two carts for dross at the defender’s colliery at Morrison’s Haven, and while he was in the act of tilting up a hutch in order to empty the dross a loaded hutch came running along the rails where he was standing and knocked him down, the batch going over his right leg, which was broken. The fault alleged is that the hutch was culpably and recklessly set motion by a banksman named Montgomery, and was dispatched along the rails without anyone having control over it, and without warning to the pursuer. The defenders deny this, explain that Montgomery was not a servant of theirs, but a contractor, and that the pursuer had gone to the pithead without their authority or invitation, and voluntarily took part in the moving and emptying of the hutches.

07/01/1888 – Shetland Times – The Prestongrange Coal and Fire Brick Company Limited, Prestonpans are prepared to quote for delivery f.o.b, packet or steamer at Leith of all kinds of fire clay goods, sanitary pipes and traps, oven soles, fire bricks, vent linings, gas work bricks, street galleys etc. Cheapest prices are given. By buying directly all intermediate profits will be saved to the consumer. No Agents. G.B Luke General Manager.

26/03/1888 – Greenock Telegraph – A jury, sitting with Lord Adam in the Court of Session on Saturday, returned a unanimous verdict for the defenders in an action for damages by a workman against the Prestongrange Coal and Fire Brick Company.

25/05/1888 – Haddingtonshire Courier – The Prestogrange Colliery case. The action, in which Charles Sutherland sued the Prestongrange Coal and Fire Brick Company for damages in respect of personal injuries sustained at their works, was finally determined in the Court of Session on Saturday. The jury before whom the case was first tried awarded £100 of damages, but a new trial was allowed, on the ground that during an interval of the trial one of the jurymen had gone to the works, and had at his request been shown the scene of the accident. The second jury found for the defenders. On Saturday the verdict was applied. Counsel for the pursuer opposed the motion of the defenders for expenses of the first trial on the ground that the defenders should have given notice at the time of the juror’s visit, and that it was owing to their fault that the juror was shown the works. The Court allowed neither party expenses of the first trial.

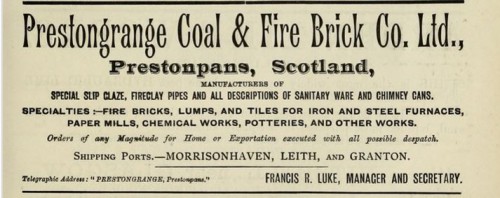

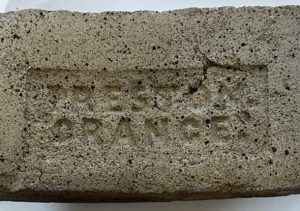

28/03/1892 – Business card/memorandum. The Prestongrange Coal & Fire Brick Coy Ltd, manufacturers of refractory fire bricks, Preston Pans. Fire brick brand Preston Grange.

Below – 1893 – Presongrange Brick and Fireclay Works.

Below – 1893 – Advert – Prestongrange Coal & Fire Brick Co Ltd – Prestonpans – Morrisonhaven Leith and Granton. Francis R Luke.

01/06/1893 – Glasgow Herald – Mr A. C. Morten is to have an interview with the Home Secretary, with the view of impressing upon him the desirableness of appointing a large number of mining inspectors, so that mines may be periodically examined in order to see whether they are in a dangerous condition, instead of waiting, as at present, until a colliery accident occurred and then making an inspection. The hon. gentleman will on Friday ask the Home Secretary whether it is correct that in Northumberland and Durham mines the so-called boys, from 16 to 21 years of age, are obliged to work about 11 hours in the mine; whether he can state what proportion these boys form to the men, and whether the ballet for and against the eight-hours day these so-called boys were allowed to vote? He will also ask the Chancellor of the Exchequer whether he is aware that the Prestongrange Colliery and Fire-Brick Works, East Lothian, have been ruined and closed by the excessive royalties and way leaves taken by the Crown and others, whether he is aware that about 250 men have been thrown out of work thereby, and whether he will reduce the royalties so as not to interfere with the trade and business of this company.

01/09/1893 – Glasgow Herald – Wages dispute between Collieries and workers – Mr Nelson, Prestonpans reported on behalf of the Prestongrange Brick and Tile Works that the men there had been offered a 10% increase and if the prices warranted more they would get it.

Below – 11/08/1893 – Glasgow Herald – Prestongrange Coal and Fireclay Works for sale. Mr Francis R Luke, General Manager.

Mid-1890s – The 1985 publication ‘A survey of Scottish brickmarks’ suggests that the Prestongrange Fireclay Goods Manufactory operated teh works around this time.

15/03/1895 – Ardrossan and Saltcoats Herald – Prestongrange Coal and Fireclay Company Limited in liquidation. Colonel Aitchison of Drumore, Preston Pans holds the mineral rights.

16/05/1895 – Dundee Advertiser – The Prestongrange Colliery which has been for some time in liquidation has been taken over by the Morrishaven Coal and Fireclay Company and Mossend Steel Company.

18/05/1895 – Glasgow Herald – Circulars have been issued by the Summerlee and Mossend Iron and Steel Company intimating that they have acquired the business of the Prestongrange Coal and Fire Brick Company Limited at Morrison’s Haven, Prestonpans. They have also leased the harbour at Morrisons Haven.

1895 – Strike at the Prestongrange mine which had recently been acquired.

24/06/1896 – The Scotsman – Summerlee and Mossend Iron and Steel Company Limited issue of preference share capital … There is at Prestongrange Colliery, belonging to the Company a Brickwork and Fireclay Pipe Work which we value at £4500 …

1897 – Summerlee and Mossend Iron and Steel Company, Fire Brick Manufacturers, Preston Pans.

23/06/1899 – Dundee Courier – Excursion – About 800 of the employees of the Prestongrange Mining and Brickworks, Prestonpans, had their annual excursion to Perth yesterday. After “doing the lions” dancing and sports were engaged in with great spirit on South Inch.

05/12/1904 – Edinburgh Evening News – Accident at the Prestongrange Brickwork – Mr Neilson, manager of the brickwork at Prestongrange Colliery, had his right hand cut off by a brickmaking machine there on Saturday.

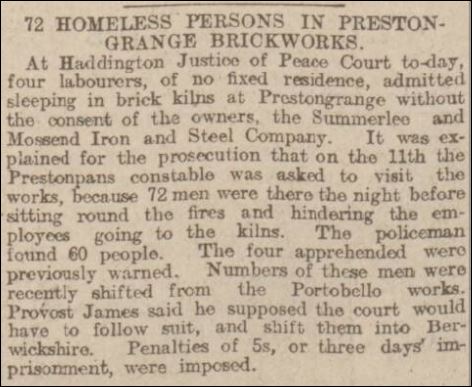

Below – 14/03/1905 – Edinburgh Evening News – 72 homeless persons keeping warm at Prestongrange Brickworks.

Below – 1906 – Preston Grange Brick and Fireclay Works.

1907 – John Haliday is the manager of Preston Grange Brick and Fireclay Works.

1910 – A Hoffman continuous kiln is built on site.

12/04/1911 – The Scotsman – German tariffs – The other night, a gentleman on behalf of his opponent had been speaking in Longniddry. He meant Mr Charles Lyall, M.P., for South Edinburgh. Mr Lyall had pointed out while not wishing to make any statement derogatory of him, that he (Mr Hall Blyth) was going about the constituency asking for votes on the ground that he was a moderate man. That was quite right. He was a moderate man. But Mr Lyall had further said that he (Mr Hall Blyth) had gone to Prestongrange and proposed a little tax on the pipes of Prestongrange and that a farmer, for instance, who was going to do a little drainage would have to pay a little more for the pipes on the account of the moderate tax proposed by this moderate man. That was a most gross misrepresentation of what he (Mr Hall Blyth) had actually said, not only at Prestongrange itself but at Haddington the other night. That could be put into the mouth of anybody. He was using the matter as an argument for Tariff Reform. He was always looking out for things to prove his case. He went there the other day and had a talk with the manager of the Prestongrange Brick and Tile Works, which were part and parcel of the colliery. The manager told him that for many years they had done a large trade in Germany, but latterly that Germany had discovered that she had fire-clay of her own and she had taught her men to be able to manufacture the smaller size of pipes. For the larger pipes, Prestongrange was still doing trade in Germany. They could not send the smaller pipes because Germany had put such a large tariff on those pipes that Prestongrange could not get them into Germany. He went on to say that if we had taken the policy of Tariff Reform we would have shown the German nation how we would treat them. One of the great things Germany sent to this country and one of the great industries of Germany was hock, which came in here with nominal taxation. If we had a free hand we could soon stop German hock coming into this country by putting on it a large duty. That would not affect any working man in the country, but there was a large consumption in this country of hock. If we had the power Tariff Reform would give we could have gone to Germany and said: “Let those pipes in from Prestongrange or we will keep out your hock.” Was that anything like what Mr Lyall represented him as saying?

18/04/1921 – The Scotsman – Miners dispute – … fireclay workers in the manufacture of bricks, drain pipes, and the like at Prestongrange were down on Saturday at the Works inquiring if they could restart.

Below- 13/06/1929 – Summerlee Iron Company, Prestongrange Brickwork railway wagon ticket.

Below – 1938 – Preston Grange Brick and Fireclay Works.

Below – 1944 – 1963 – Preston Grange Brick and Fireclay Works.

1947 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests that the works were operated by the National Coal Board during this period.

1961 – 1962 – Directory of British Clay Products and Manufacturers – Prestongrange Brickworks. See NCB Scottish Division. Lothians area). Fireclay bricks and pipes. Common bricks. Trade name ‘ Prestongrange’.

1962 – Clay Worker – Manager for Prestongrange Brick and Fireclay Works, situated in the Lothians area of Scotland, producing 6000 tons per annum, salt-glazed fireclay pipes and fittings. Which are fired in 11 round down draught kilns; and about 225000 common bricks per week, manufactured by the stiff plastic process from coal measure shales and fired in one 24-chamber Hoffman continuous Kiln. N. C. B. Brickworks Exec. Codsall, Wolverhampton.

1969 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests that the works were operated by the Scottish Brick Corporation during this period.

1975 – Brickworks closed?

Clay was not dug at Prestongrange, it lies too close to the coast and the underlying rock is Carboniferous in age; it was imported from the Upper Birslie Plantation.10 The site of Prestongrange was used due to its coal resources and Morrison’s Haven, at that time a gateway for exporting numerous products from all over the Lothians. Later, the harbour became useful for importing china clay from the south of England, a cheaper and higher quality of clay. The extracted natural clay from the area around Upper Birslie is known as ‘Fireclay’ and the formula is (in most cases) Al2O3.Si2O2.2H2O being a form of Kaolinite clay. It comprises approximately 40% aluminium oxide, 45% silicon oxide and 15% water. Also included in the clay varying but small concentrations of iron, magnesium, titanium sodium, potassium and free silica. (P23)

Below is a PG wooden brickmark stamp

Below – A drainage block or flat stone found by Ian Suddaby on the River Esk near Dalkeith. Stamped along one side with the full word “Prestongrange”

Below – An unmarked brick found in abundance around the peripheries of the Prestongrange Works and possibly made there.

.

Below – 11/09/2018 – Photographs of the Hoffman kiln at Prestongrange.

.

.

.

.

.

.

Below – Both the next 2 photos show the ‘tunnels’ running along each end of the kiln connection both firing chambers.

.