Canmore

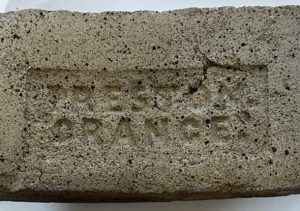

Boghead Brick and Fireclay Company, Bathgate, West Lothian.

1886 – Gillies Brothers, brick and tile makers, Boghead Fireclay Works. (Page 942).

15/04/1893 – Glasgow Herald – New company … The Boghead Brick and Fireclay Company. The object of this Company is to purchase the business and plant of Gillies Brothers, Brick and Fire Clay Manufacturers, Boghead, Bathgate and carry it on in the same or an extended form. Capital £3000 in £1 shares. Registered Office – 21 St Andrew Square, Edinburgh. The subscribers – G.Gillies, Brickmaker, Bathgate; R.Lynn, Dowanhill, Glasgow; R.C.S.Bruce, Jewel case maker, Edinburgh; A.B. Bruce, Goldsmith, Edinburgh; G. Mill, S.S.C, Edinburgh; W.R.Mann, Steel Founder, Leith; P. Fairweather, Butcher, Edinburgh.

Below – 22/09/1894 – West Lothian Courier – Boghead Brickworks employee’s excursion. Mr Gillies, the works manager accompanied them by rail to Leith and around the Firth of Forth by steamer.

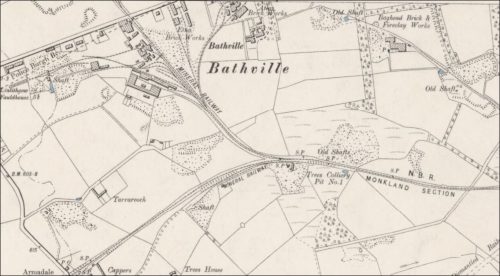

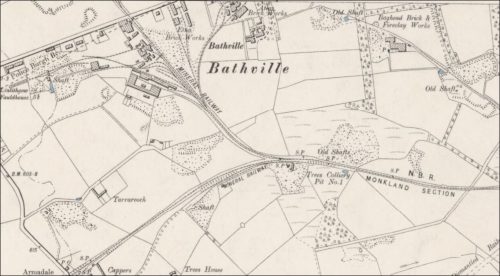

Below – 1896 – Boghead Brick and Fireclay Works.

25/07/1896 – Linlithgowshire Gazette – In the small debt court at Linlithgow an action was recently raised at the instance of Donald Tulloch Sutherland, draper, Bathgate against Messrs Gillies Bros, Boghead Fireclay Works, Bathgate and George Gillies, brickmaker, Muir Road, Bathgate, the only known partner of the said firm, now dissolved, as such partner and individual for £50 being the balance of a bill for £100 dated 25th July 1884, drawn by the pursuer and accepted by the defenders and payable 3 months after the date. The bill had been signed along with the pursuer, but defenders had failed to meet the obligation and recourse was had against the pursuer here, who now sought relief from the defenders. On 21st Jan 1893, the defenders paid £50 to account, and the balance was the sum now sued for. On the case being called in the Court on Friday last, Mr Gardner, for the pursuer, said in reference to a motion for adjournment, that, as advised by his client, he could not very well consent to any further adjournment of the case. The Sheriff said if it was an action under a bill he was afraid he was bound to decide it at once. Gardner said it was for a bill, and could not see that there was any defence. Mr Dodds, for the defender, said that after looking into the matter fully he thought he could not do otherwise than withdraw the case altogether. It was all about a payment of £25 and he was afraid it would impossible for him to prove it. He would, therefore, consent to decree. A decree was given accordingly of consent.

28/11/1896 – West Lothian Courier – A meeting of the members of the Bathgate pipe band was held on Thursday evening when there was a large attendance. Mr George Gillies, manager of the Boghead Brick and Fireclay Works was elected president of the band …

28/08/1897 – Linlithgowshire Gazette – An excursion organised by a committee of the employees of Bathville Steel Works and Boghead Brickworks took place on Saturday to Kirkcaldy where a grand band contest and flower show were being held. The train ran from Armadale Station calling at Bathgate and about 500 people took advantage of the trip.

13/11/1897 – Linlithgowshire Gazette – A petition for cessio. The following notice appeared in the Edinburgh Gazette of Tuesday night. George Gillies, bricklayer, Muir Road near Bathgate, only partner of the firm of Gillies Brothers, Boghead Fireclay Works, Bathgate, to be examined within the Sheriff Courthouse, Linlithgow 26th November at 1230 o’clock.

Below – 04/12/1897 – Linlithgowshire Gazette – A brickmakers difficulties – Left in the lurch when the ship began to sink – In Linlithgow Bankruptcy Court on Friday, George Gillies, bricklayer, Muir Road, Bathgate, the only partner of the firm of Gillies Brothers, Boghead Fire Clay Works, Bathgate was examined in a petition for the benefits of cessio at his own instance against his creditors … Examined by Mr Kidd, petitioner stated that he was formerly engaged as a brickmaker in Bathgate. He conducted business in premises belonging to Mr Maxwell Durham of Boghead. He left these premises about 5 years ago. When he left the premises he disposed of his business to the Boghead Brick and Fire Clay Company Ltd, whose business is now absorbed in that of Dickson and Mann. Petitioner considered that his business at the date of sale was almost insolvent. As consideration for the sale, he received from the first-mentioned company 50 of their £1 shares, with 15 shillings paid thereon …

Below – 16/07/1898 – Linlithgowshire Gazette – Theft of brass.

03/12/1898 – Cumberland and Westmorland Herald – The enterprising firm of Messrs Muir and Co Limited, Armadale near Glasgow have purchased the Boghead Fireclay Brickworks from Messrs Dickson and Mann. This now makes three large works under the control of the company, the whole being under the supervision of Mr Robert Muir, nephew of Mr Muir, Clifton. The latter gentleman’s son, Mr Robert Muir, Jun and late manager at Clifton Potteries also holds an important position under this firm.

10/08/1900 – Linlithgowshire Gazette – Wanted, a few women and girls. Apply Boghead Brickworks, Bathgate.

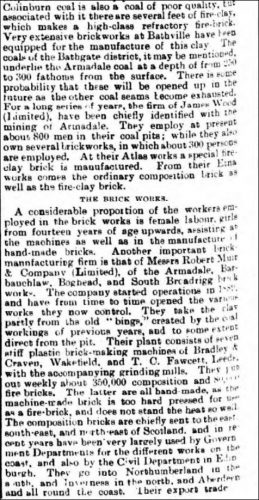

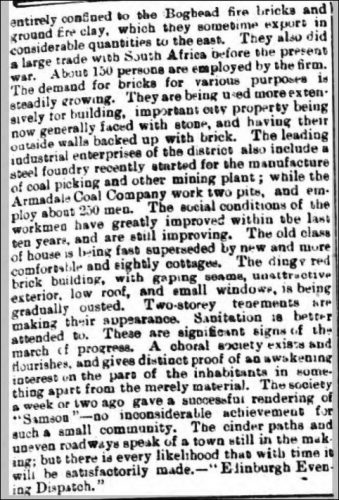

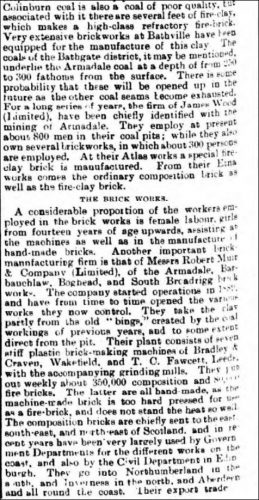

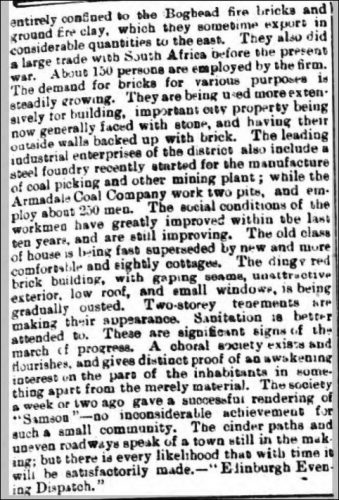

26/10/1900 – Linlithgowshire Gazette – Our local industries – Brickmaking – One of the most important of our local industries is that of brick making. Quite a number of works, some of them of considerable dimensions, are devoted to this branch of trade, and it would astonish our readers were they told of the vast quantity of bricks which weekly leave this district. That the industry is flourishing in a most remarkable degree is evidenced by the many extensions carried through at most of our local brickworks in recent years and certainly, within the last ten years, the progress made has been enormous. There have been one or two local factors which have lent themselves this increase. There is, for instance, an abundance of clay of a suitable character; then the presence of so many collieries the district makes this a particularly good field for brick making; and not the least of the factors which have contributed to the success of the industry has been the enterprise displayed by the various firms which devote themselves to this class of business. Brick making appliances play so large a part the manufacture of bricks that, in comparison to the large output of material, the number of hands employed is small, yet when we take into account the number and the extent of the brickworks in this neighbourhood, and the very large business which is done, the number of workers, male and female, engaged in this particular branch of trade run into many hundreds. The oldest brickwork in the district is that owned by Messrs Robertson, Love, and Co., it having been in existence for nearly 30 years. Robert Muir and Co. had also an old brickwork before they started their present one. Boghead Brickworks were erected by Mr Gillies of Boghead, and the works were originally used in the manufacture of fire brick and ground fireclay. Years ago the business changed hands, Mr Gillies parting with it to the Boghead Fireclay Company. It was then a small concern, but to meet the growing demands of trade this firm were obliged to considerably enlarge it. They afterwards sold the works to Messrs Dickson and Mann, who a few years later disposed of it to the present proprietors, Messrs Muir and Co. As the demand for the bricks produced in the works continued to grow, a further large addition had to be made, and yet another is in progress. The enterprising firm of Messrs Muir and Co. are, we learn, also making preparations for turning out at these works composition bricks, in addition to those classes bricks presently produced. The works at Bathville owned by James Wood and Co., are of vast dimensions and are divided into two portions, the Atlas and the Etna Brickworks. The Atlas Works are entirely devoted to the manufacture of firebricks, while at the Etna Works composition bricks are produced. An idea will be had of the extent of these works when it is stated that they cover nearly twenty acres of land. In the Etna Works, some 100 hands are employed, while at the Atlas Works there are about 50 workers. At both works, the firm could employ many more hands, but at present, when the trade is so busy, brick workers are not to be got. The Atlas Brickwork is the older of the two. It was begun in a small way a good many years ago by Mr Robert Fleming of Coatbridge, who had as a partner Mr Kopel Moritz. The latter subsequently dropped out of the partnership and removed to the Armadale Brickworks. He continued to be associated with those works till his death, after which the works wore acquired by Mr W. D Samuel and Mr Robert Muir, the present managing directors and original partners of Robert Muir and Co., Ltd., who own Armadale, Barbauchlaw and Boghead Brickworks, and whose fireclay and firebrick products are exported in large quantities to Singapore, Rangoon, Durban, Delagoa Bay, etc. Mr Fleming carried on the Atlas Works himself for some years after the dissolution of his partnership and on his death, the business was acquired from his trustees by Mr Wood of Bathville. Mr Wood threw into the concern considerable enterprise and business ability. He considerably developed the trade and not only made extensive enlargements at the Atlas Works but on his adjoining ground, he erected the Etna Works. Both works are fitted with the latest machinery and improved appliances for the manufacture of all kinds of bricks, and a very large and rapidly growing business is done by the firm. James Wood, Ltd., have their two works fully employed, so far as labour is to be had, in the production bricks alike for the home and export trade. It would be divulging what the firm might regard as a trade secret were we to state the average weight of the bricks which weekly leave their works. It is enough to say that weekly production is enormous and that it is continually increasing. The firm’s products find their way into almost all parts of the world. The firm have good agencies and a splendid connection abroad, and firebricks and ground fireclay are largely exported to Bombay, Calcutta, and elsewhere. As illustrating the advancement made in the method of brick making, it may be mentioned that the kilns now used for the manufacture of composition bricks are those of the continuous Hoffman principle, whereby immense heat is transferred from one chamber to another, and an immense saving of coal is ensured. In the older brickworks in the district, the Newcastle kilns are still in operation for making firebricks. With these kilns, makers have to make their bricks and dry them in a shed with whatever heat they can get. If steam is employed, it is let underneath the kilns by flues, and the heated air dries the bricks. Under the new Hoffman kiln system, however, the bricks are simply taken from the machine and put into the kilns and the hot air follows gradually around. After the brick chamber is emptied it is immediately filled with fresh or green bricks and the heated air from the burning chambers is conducted round in flues underneath the floor of the kilns. By the new method, the bricks are of course quicker and better made. The fireclay comes from the pits in ‘trips’ and the workmen empty it on to a travelling table and hence into a grinding mill. The clay is then lifted from the pit under the grinding mill by elevators up to the sifting loft. Then it goes through sieves, travels down a shoot to the mixer, where there is a constant stream of water flowing and where by means of knives attached to the machine the clay is mixed and pressed into the brick making machine. The clay comes from this machine as a perfect brick. Thereafter the bricks are placed in the Hoffman kiln and in 14 days time they have taken the form of the first-class commercial article ready for market. It will be seen what a revolution this improved method of brick making must have wrought in the brick making trade when it is mentioned that under the old system in good weather, 14 days were required to dry the hand made brick, while 14 more days were occupied in the burning of it. At present an addition consisting of a large drying shed of considerable dimensions is being made to the Etna Works and this addition, when completed, will permit of a greater output of material and lead to the employment of additional hands. The works are managed by Mr Findlay who succeeded the late manager, Mr Hugh Dunlop, who had been connected with the works from the start and who died a few months ago. We can only mention the other brickworks in the district. That belonging to Robertson Love and Co is prospering like others. Mr John Nimmo and Sons have done a fair business at their works while the Armadale Coal Company have kilns in the course of construction for a large new brickwork. The possibilities of the brick making trade of our district are very great. Situated as Bathgate is almost equidistant between our 2 great commercial cities, Edinburgh and Glasgow, and on the mainline of the railway, there is every certainty that this industry has a bright future. Its growth has been rapid but it is only still in its infancy. When the present factors which are tending to so greatly to depress the building trade have been removed and when the money market is such that it will permit the speculative builder to build as before, the trade will come away with an almost unprecedented boom and much of the new business will naturally come to this district. It is therefore not to be wondered at that some firms are, in anticipation of this demand, enlarging their works and further additions may be anticipated. From a calculation made by a gentleman immediately associated with the trade, some 120,000 composition bricks leave the brickworks in this district daily.

28/12/1900 – West Lothian Courier – The recent storm. Great damage to property … The Boghead Brickworks did not escape scatheless. At this place, a stack 60 feet in height, was blown down and destroyed a large drying shed that had been recently extended. Some thousands of bricks were rendered useless …

1901 – Directory of Clayworkers – Dickson & Mann, Ltd., Boghead Brick and Fire Clay Works Armdale Station, Linlithgowshire.

Below – 17/05/1901 – Linlithgowshire Gazette – Boghead Brickworks opening additional works. It is now eight years since the works of Messrs Robert Muir and Co., Armadale, were floated as a limited company and since that time a steady progress has marked the efforts of the directors. It is now fully two years since the company acquired Boghead Fire Brick Works from Messrs Dickson and Mann, and during that time they have carried out extensive alterations and improvements at the works, and today the works are fitted with all up-to-date appliances for the manufacture of bricks. With the view of meeting the increasing demand for their production, large additions have recently been erected, and on Monday these were formally opened in the presence of a large and influential gathering, including a number of the shareholders of the company. The buildings, which consist of an engine room, machine room, grinding mills, and cold store, are large and have plenty of floor space. The new plant so far has been fitted by Messrs T. C. Fawcett, Ltd., of Leeds, who are present exhibiting machinery at the Glasgow Exhibition. In the machinery room, only one machine has been put down, but ample space has been left for the introduction of another should the demand require it. In juxtaposition to the machinery room a largo 14- chamber kiln has been built, with a holding capacity for 160,000 bricks. As has been said, the opening ceremony took place on Monday, when among others the following ladies and gentlemen were present:—Mrs W. D. Samuel; Mrs Samuel, sen.; Mrs G. Muir, Mrs R. Muir, Miss Muir, Miss Russell, Miss Dick, Mrs Henderson, and Miss Henderson, Fauldhouse; Mrs Ranklne, Edinburgh; Mr Russell, chairman of the directors; W. D. Samuel and R. Muir, managing directors; Mr A. L. Muir, director; Mr Caesar, secretary of the company; Provost Gordon, Bathgate; ex-Provost Dougal, Bathgate; ex-Bailie Waddell, Bathgate; Councillor Thom, Bathgate; Mr James Sinclair, Bathgate; Mr John Binnie. Bathgate; Mr James Carlaw, Bathgate; Blyth, manager, Owen Stone Works, Bathgate; James Rankine, Edinburgh; Gavin Russell, Falkirk; Mr Gordon, solicitor, Forres. The opening ceremony was performed by Mrs Robertson – Durham, who was accompanied by Mr J. A. Robertson -Durham, the proprietor of Boghead. After the works had been inspected, the company adjourned to the engine room, where Mr Samuel, addressing the company, said that, in the name of Messrs Robert Muir and Co., Ltd., he welcomed them. There was an old proverbial saying that “Everything comes him who waits.” He believed that the directors of Robert Muir and Co. had never in all their former experience felt the truthfulness of that statement, nor could it appeal to them with more force than it did that day. That day the hopes and aspirations of the last two years were now about to be realised. He was very glad to see such a large representation of the shareholders of the company present. They seemed now to be taking an interest in the company’s affairs. It was his special duty to introduce to them the Laird of Boghead and his good lady. (Applause.) Mr Durham had very kindly consented to give them a send-off. Mr Durham had assured him that he had no knowledge of bricks or brickmaking, and he believed him; but nevertheless, he had undertaken to make the first brick—(applause)—and was certain, that if he put that energy into the work that he imparted into everything he did, Boghead Brickworks would be sent off full steam ahead. (Applause.) He had much pleasure in asking Mrs Durham to turn on the steam. Mrs Durham, in a graceful manner, turned the wheel, and the piston was smoothly set agoing amid applause. With the machinery in motion, the party adjourned to the grinding mill, where Mr Robertson -Durham assisted at the work. He then ascended the brick making machine, lifted the bricks as they came from the machine, and put them on a trolley, after which he inspected the kiln. The company then adjourned to the machine room, where they were treated to cake and wine by the directors. Mr Robertson – Durham said he and his wife had been greatly impressed by what they had seen of brick -making. Brick making was a very ancient occupation but he did not think there was any occasion like the present when they were employed at brick making on the banks of the Nile. He believed Mr Muir would have been most acceptable there. The great difficulty at that time was the finding of straw but they had seen that day how Mr Muir emptied what they called rubbish into a machine, which turned out the most beautiful bricks they could possibly wish. If that could have been done in the time the Pharaohs, he was perfectly certain Mr Muir would have been Prime Minister or something greater. (Laughter.) He did not know where their friend Joseph would have been. (Laughter.) Mr Robertson – Durham then referred to the strides that had been made in the brick making trade and referred to the ancient method and the difficulties attending it. Now they had only to turn on the machinery and the bricks came. After referring to the capacity of the machinery with regard to the turning out of the bricks, he said there was nothing like success, and he hoped and trusted the directors would be rewarded for the energy they had shown, and he trusted that the efforts the directors would be crowned with success far beyond what they expected. (Applause.) He asked the company to drink to the “Success of Messrs Robert Muir and Co., Ltd.” The toast having been enthusiastically pledged, Mr Russell, chairman of the directors, in reply, thanked the company for the kind expression which had been made for the success and prosperity of the undertaking which they had all so much at heart. Some eight years ago the company emanated from a small concern and was floated with very moderate calculations, which he was glad to say had been fully verified. They had been very modest in their calculations, although their aspirations had been high, and it was hardly possible to say whether these had been realised. One thing he was sure of that nothing would be awanting on the part of the management to make the works a real success. He had to thank them for their kind wishes for the prosperity of the company. He would ask them to drink to the health of their landlord; long might he occupy the eminent position which he had attained in his profession, as well as on the Estate of Boghead. (Applause.) He gave them “The Laird of Boghead and his good Lady Mrs Robertson – Durham.’’ The toast was heartily pledged and suitably acknowledged by Mr Robertson – Durham. Mr Caesar proposed “The victors” which was replied to by Provost Gordon A. number of other toasts were proposed and duly responded to.

Below – 17/05/1901 – West Lothian Courier – Boghead Brickworks opening additional works

.

.

.

Below – 21/03/1902 – Linlithgowshire Gazette – An article discusses the Boghead, Bathville, Etna and Atlas Brickworks of West Lothian.

.

1903 – Robert Muir & Co Ltd – (composition & fireclay brick manufacturers, red & white composition bricks, boiler blocks, flue covers &c.), Armadale, Barbauchlaw, Boghead & South Broadrigg brickworks, Armadale Station, Linlithgowshire.

09/01/1903 – Linlithgowshire Gazette – James Marshall, boy, 14 years of age, residing with bis parents at Thomson’s Land, met with a serious accident on Tuesday afternoon, about 3 o’clock, while engaged at Boghead Brickworks, The boy, whose duty it was to attend keeping the passage of the ground clay clear in the loft while it was being conveyed by the bucket lifters, had somehow got into position close to the belt, which unhappily broke, striking him on the bead, fracturing his skull, and rendering him unconscious. Having been conveyed home and surgically examined, there were found to be four wounds on his head, more or less dangerous.

21/11/1903 – Falkirk Herald – Accident at Boghead Brickworks. Margaret Gray Kirkland, eighteen-year-old girl, residing at Shamrock Buildings, Hopetoun Street, Bathgate, and engaged as a lifter off the machine Boghead Brickworks, met with a painful accident at the works on Tuesday afternoon. The brick making machine had been stopped for the purpose of being oiled and was just being re-started. The girl happened to put in her right hand to remove something when the stamp came down crushing three of her fingers, crushed them rather severely. On being removed home, Kirk dressed the wound and ordered her removal to Edinburgh Royal Infirmary.

04/03/1904 – Linlithgowshire Gazette – An alarming burning accident took place at Messrs Muir and Co.’s Boghead Brickworks at nine o’clock on Monday morning, which a young woman named Kate Pake, 19 years of age, was severely burned to the right side of the face, right arm, and breast. The unfortunate woman was at work in one of the kilns, which was lighted by a Wells paraffin torch lamp sitting upon a pile of bricks and somehow when she was in a stooping position the lamp toppled over her shoulder, spilling the oil over her dress, which was in at once in a blaze. Every effort was made to extinguish the burning clothes, which was at last successfully done a man wrapping his coat around her, but not before she had been badly burned. She was conveyed home to her sisters (Mrs James Hob), Main Street with whom she lives, and Dr Anderson attended and dressed the wounds, which were considered of such a serious nature as to advise her removal to the Royal Infirmary, Edinburgh.

09/12/1904 – Linlithgowshire Gazette – A very descriptive story about one of the steam engines that drove the clay mill on the south side of the line at Boghead Brickworks going out of control. It seems the regulator malfunctioned and the engine got faster and faster until the flywheel disintegrated. Lumps of metal flew great distances and narrowly missed hitting a moulder and a pan mill man. No one was killed or injured. That part of the works were closed for a day or so while repairs were made.

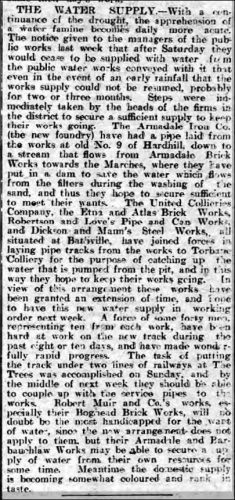

16/06/1905 – Linlithgowshire Gazette – The drought is having some effect now on the public works. The want of water has thrown a number of workers idle at one brickworks at Boghead, where the boilers are fed from a small burn that has become dry.

17/11/1905 – Linlithgowshire Gazette – At Linlithgow Sheriff Court Tuesday, before Sheriff-Substitute Macleod, John Swan, engineman, Bathgate, was charged with having on the 4th inst, at Boghead Brickworks occupied by Robert Muir & Co, assaulted Robert Tweedie. Jun. brickworker, by beating him with the fist. He pleaded guilty, under provocation, and explained that the boy had been running about playing himself and when he asked him to attend his work the lad swore him and gave him a lot of impudence. The Fiscal said the boy thought the accused had nothing to do with him. This, boy and some girls had been skylarking and (the Fiscal) believed the boy had been a little rude but the accused had gone a little too far. The Sheriff said he had doubt at all that accuser’s motive in speaking to the boy was an excellent one. That was to say he had his employers’ interests at heart, but it was necessary to bring him to Court in connection with this charge in order to let him understand that however impudent a boy might be, he must not strike him. He (the Sheriff) thought the fact that he had been down would have taught him that lesson, and it would not be necessary to impose any punishment.

02/02/1906 – Linlithgowshire Gazette – Thomas Hamilton, an elderly man, Boghead Brickworks (R. Muir and Co ), fell over the loading bank sometime between Wednesday night and Thursday morning and had his right thigh bone and three ribs fractured. The men whose duty it is to look after the burning of the bricks found the old man lying near to the door of the bothy, suffering great pain. They dragged him into the hut and learned from him that someone had pushed him over the embankment. The story gets little credit, for it is believed stumbled over himself. It was found necessary to send the injured man the Edinburgh Royal Infirmary.

05/10/1906 – Linlithgowshire Gazette – Robert Muir & Co of Armadale, Barbauchlaw and Boghead Brickworks are about to become mine owners, insomuch as they are going to open a clay mine in the vicinity of their Barbauchlaw Brickworks at the East end of the town.

24/05/1907 – Linlithgowshire Gazette – Messrs Robert Muir and Co., Ltd., fireclay brick manufacturers, Armadale, Barbauchlaw, and Boghead Brickworks, gave a complimentary dinner to Mr Robert Boyd and his workmen in the Crown Hotel on Friday evening, on the completion of Mr Boyd’s contract sinking a pit and driving a daylight mine for coal and clay at Barbauchlaw Works. Bailie Samuel, managing director, occupied the chair, and after justice had been done to the excellent viands purveyed Mr Greig, glasses were charged, and a splendid programme of toasts, song, and story enlivened a mirthful and enjoyable evening.

08/11/1907 – Linlithgowshire Gazette – The south side or firebrick section of Messrs Muir and Co.’s Boghead Brickworks was closed down indefinitely last week. A good stock has had been laid in. The demand for this class brick is mostly foreign and comes in shipload orders, but they have been rather scarce of late.

20/03/1908 – Linlithgowshire Gazette – A boy named Wm. Stenhouse, machine cleaner, residing in Smith’s Buildings, Chapel Lane, Bathgate, met with an accident on Monday while at his work at the Boghead Brickworks. The lad’s duty was to keep clean the brick table and seeing that some loose clay had got onto the table, he thoughtlessly put his right hand in too far while the machinery was in motion. Before he could withdraw his hand again, the stamping machine came down, cutting off his thumb between the nail and the first joint. The lad was taken to Dr Kirk’s surgery, where his injuries were dressed.

08/01/1909 – Linlithgowshire Gazette – Our County in 1908 … The foundries and brickworks are not so busy as usual and could do with a great deal more work. Messrs Robert Muir & Co, owners of Armadale, Barbauchlaw and Boghead Brickworks having been at law with the United Collieries Company regarding their lease of South Broadrigg Brickworks had their case settled in their favour in the House of Lords early in the year and resumed operations at the works on the 4th July.

24/09/1909 – Linlithgowshire Gazette – New Management at Muirs Brickworks – Hugh Goldie, who has managed the brickworks and coalmine of Messrs Robert Muir and Ltd., for past three years, having accepted an engagement of similar nature Bonnybridge, left on Wednesday of last week. In order to fill the vacant position. Messrs Muir and Co., who own Armadale. Barbauchlaw, and Boghead Brick and Pipe Works, and Coal Mine have had to engage a manager for the brick and pipe works, and also a manager for the mine. Mr James Gillespie, late of Turner and Co., Portobello, took up the duties of managing the brick and pipework on Tuesday, and Mr Heaps, from Blackbraes, a young certificated mine manager, has taken over the management of the mine.

Below – 1910 – Boghead Brick and Fire Clay Works.

04/08/1911 – Linlithgowshire Gazette – Mr Robert Heaps, manager of Robert Muir and Co.’s coal mine at their Barbauchlaw Brick and Can Works has resigned and leaves tomorrow to fill a more important position. His successor will be William Shields, who at present holds the position as oversman at Northrigg Colliery at the United Companies service. He commences his new duties on Monday. At Boghead Brickworks, owned by Messrs R. Muir. Ltd., Mr James McColl of Half-Way House, Cambuslang has been appointed manager and commences his duties on Monday.

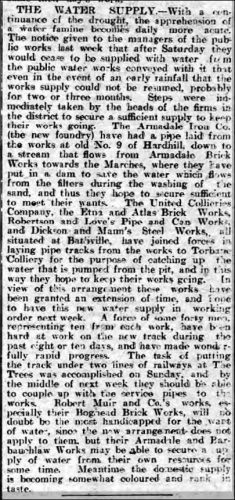

Below – 25/08/1911 – Linlithgowshire Gazette – Drought causes local firms to unite in order to construct a pipeline to bring in water – United Collieries, Etna and Atlas Brickworks, Robertson and Loves Pipe and Can Works. Robert Muir and Co’s works at Boghead brickworks will be disadvantaged as they will not be connected to this new supply but their Armadale Barbauchlaw Works may be able to secure a supply of water from their own resources.

Below – 1912 – La Rural – A directory detailing the area of Buenos Aires. See page 628. Is this an advert for Muir of Boghead exporting fire clay to Buenos Aires?

1912 – 1913 – R Muir and Co, 196 St Vincent Street, Glasgow.

30/04/1915 – Linlithgowshire Gazette – Armadale – An old Armadale boy killed – Mr Robert Muir, late managing director of the firm Messrs Robert Muir and Co., Ltd. Armadale, Barbauchlaw, South Broadrigg, and Boghead Brickworks, now residing at Carfin, has just received word from the War Office that his son Robert, who was serving with the Guards, has been killed action. The young soldier received his schooling at Armadale, where he made a large number of friends, with whom he continued in the closest intimacy, and was engaged to be married to Miss Grace Shaw. With the deceased’s parents and family and Miss Shaw, the deepest sympathy is felt.

18/02/1916 – West Lothian Courier – Wanted. Wet panman for Boghead Brickworks, Armadale. Constant work, good wages. Apply to the foreman at the work.

11/01/1918 – Linlithgowshire Gazette – John McCracken, a kiln burner, who resided at 33 East Main Street, a burning accident to whom we reported hist week, died at Edinburgh Royal Infirmary Monday night. He stumbled and fell while carrying large oil lamp to fire a kiln at Messrs Robert Muir and Co.’s Boghead Brickworks. The oil from the lamp splashed about his clothes and ignited, and no one being at hand assist him, struggled as best could until he had torn all his clothes off, but not before he was severely burned about the. body, legs, and arms. He struggled into the bothy and lay down there. Shortly afterwards a tramp appeared to rest there for the night, and to him, the unfortunate man gave instructions to inform his wife, who hastily reached him and sent for the doctor and the ambulance waggon. Unhappily the doctor was attending to another case a good distance away, but Provost Greig, arriving with the motor ambulance waggon, rendered first-aid and brought the man home, where, after, being attended to by Dr Gilchrist, he was removed to Edinburgh Infirmary, where he arrived after midnight on New Year’s morning. From the first little hope was entertained of his recovery. He was 52 years of age and acknowledged by the company to have been one of their most valued servants.

12/04/1918 – Linlithgowshire Gazette – Boys leg cut off – John Wardlaw. 15 years of age, son of Mrs McCracken, East Main Street, while working at Etna Brickworks on Saturday, had the misfortune to lose his right leg. He had occasion to pass a card to one the workmen and to do so, it is reported, that he made to step over the brick making machine when his foot slipped and got into such a position on the turntable that his leg below the knee was completely severed. He was immediately conveyed to Edinburgh Royal Infirmary. On Hogmanay night his step-father, John McCracken, while engaged as a kiln burner at Boghead was so severely burned that he died in the infirmary, and in addition, Mrs McCracken has another boy dangerously ill with meningitis. The greatest sympathy is felt for Mrs McCracken in her affliction.

22/04/1921 – Linlithgowshire Gazette – Owing to the scarcity of coal, Boghead Brickworks have had to shut down this week. The other two works of Messrs R. Muir and Co Ltd, have had to go on short-time working a day now and again to keep the kilns on, as it is very costly to restart them after they get cold.

12/03/1921 – The Scotsman – The Estate of Boghead, Bathgate as previously advertised will be re-exposed for sale on Wednesday 23rd March 1921 … at the reduced upset price of £20,000 … if not sold in one lot the Estate will be immediately re-exposed in the following lots:- Lot 1. Mansion House, garden and offices along with Whiteside Home Farm, grass parks and brickwork ground – £11,500 …

18/03/1921 – Linlithgowshire Gazette – Messrs Robert Muir and Co Ltd, fireclay workers owning Armadale, Barbauchlaw and Boghead Brickworks have appointed a manager to fill the position vacated by Mr James Gillespie. The new manager, Mr Watson, comes from the Paisley District and commenced duties on Friday last.

18/03/1921 – West Lothian Courier – R Muirs and Coy’s new brickworks manager. On Friday last Mr Daniel Watson, who succeeds Mr Gillespie as brickworks manager with Messrs R Muir and Coy, Armadale commenced his studies. Mr Watson is a native of Cleland and figuratively speaking, may be said to have been born into the business. His father was in the same line and it is very interesting to note, was the first manager of the Etna Brickworks, then owned by Mr James Wood of Wallhouse and which are now owned by United Collieries Ltd. His uncle too, is in the same business and he, it is also noteworthy to state, was for a period, manager at Mr King’s Possil Brickwork, Glasgow. Mr Watson entered the brickworks at the early age of 12 years and while yet in his teens was appointed manager of Cambuslang Brickworks. From here he went as a manager to the Linwood Brick Manufacturing Company, Paisley and it is from Paisley that he comes to take over his Armadale managership. Just a little over 40, he looks the ideal manager, and his, very obviously, a great liking for and interest in the work which he has followed now for fully 30 years.

03/06/1921 – Linlithgowshire Gazette – Public works coming to a complete stand – Week after week one public work after another is compelled to shut down for want of fuel. First, the Atlas Steel Foundry had to close down, then Messrs R. Muir and Co,’s brickworks, and next Messrs Robertson and Love’s Fireclay Pipe and Can Works, and lastly Messrs Dickson and Mann, Ltd., have had to close their steel foundry, and the Etna and Atlas Brickworks, which were well stocked to begin with, have now also had to shut down for want of coal. Messrs Dickson and Mann could probably have held out little longer as far as fuel is concerned, but the opportunity is being taken to make some desirable repairs on the furnace. They are still carrying on their engineering shops, and the United Collieries are able to carry on their machine shops and wagon building shops, being little fuel required with them. All the chimney stacks being now smokeless, the air is pure that one can’t help commenting what a blessing it would be to humanity if the air pollution by smoke could be entirely eliminated. It’s a poor misfortune that does not yield some compensation.

18/09/1925 – West Lothian Courier – A charge of having stolen 236 feet of wood lining from Boghead Brickworks, Armadale on 12th July last was preferred against George Weir, miner, residing at Cappers Rows, Armadale. The accused, while pleading guilty, said this was an old brickwork. The boys were making bonfires with the wood, and thinking there would be no harm in him making a better use of it, he took four lengths. The boys were just destroying the wood, and be did not expect to be charged for all the wood. The Depute Fiscal (Mr Gammie) said there had been complaints about people taking away this wood. The Sheriff imposed a fine of 10s or five days and allowed 14 days to pay. (Note – SBH – This appears to infer that the Boghead Brickworks had been closed for several years prior to this date.)

1928 – Works closed? ( Note SBH – I need to try and confirm this date).