Carty Tileworks, Carty Port, Penninghame, Wigtownshire

Canmore

Carty Tile Works, Wigtownshire Carty Tileworks was a typical small rural tileworks, making clay drainage tiles for local markets. When built it probably shipped some of its products to market, as there were the remains of a wood-piled quay beside the works.

This view (below) shows the single kiln in the centre, with the chimney which provided the draught for it. Behind it are the single-storey wooden sheds in which the tiles were moulded and dried before being fired in the kiln.

This was one of the last ceramic drainage tile works to operate in Scotland, as flexible plastic pipes were already taking over in the 1970s.

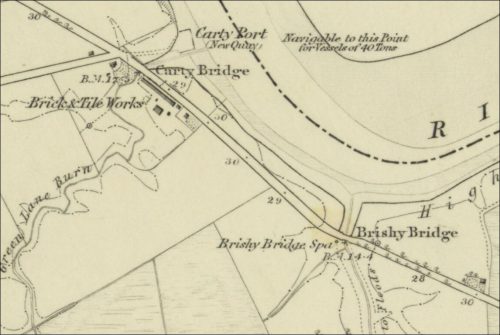

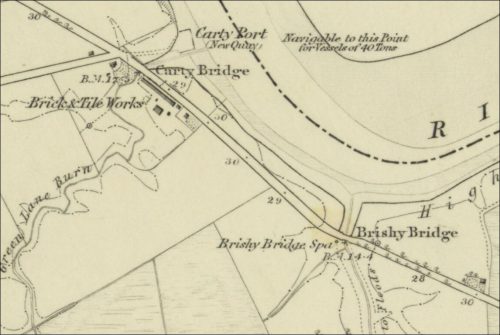

1845 – 1849 – ScotlandsPlaces – Carty Port. A new harbour constructed on the Wigtonshire side of the River Cree by the Earl of Galloway in the year 1828. Situated 2 1/2 miles from N. [Newton] Stewart 4 1/2 up the river. Boats of 40 tons may put in with safety on ordinary tides. There are two dwelling houses and a brick and tile works at it.

Below – 1846 – Carty Tileworks.

Below – 14/12/1858 – Headed notepaper – Carty, Baldoon and Millisle Tile and Brickworks – Robert Picken.

Below – 10/02/1883 – Glasgow Herald – Tile plant for sale at Carty. Apply William McGill, Carty Tileworks.

29/07/1886 – Ayr Advertiser – Quoiting – Mr Crawford, Carty Tileworks was the winner of a pair of vases presented by Mr John Hannah to the Newton Stewart Quoiting Club.

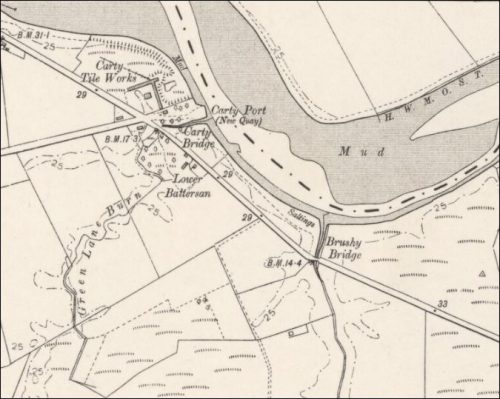

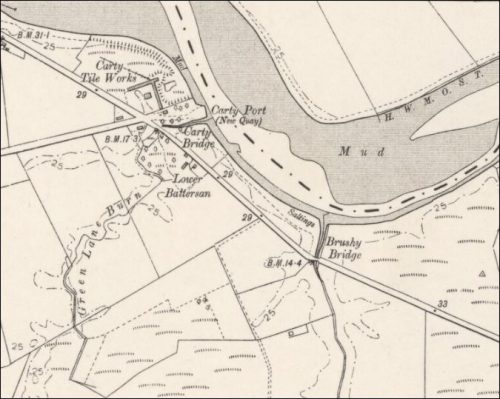

Below – 1894 – Carty Tileworks

1903 – David Crawford, Brick and Tile Maker, Corty (Carty?), Newton Stewart.

Below – 1907 – Carty Tileworks

13/08/1938 – The Scotsman – Two hour fight to save mare – Embedded in Clayhole – Fourteen men had a hard two hours struggle to save a Clydesdale mare which became deeply embedded in a treacherous clayhole on a marsh between High Baltersan and Low Baltersan Farms, Newton-Stewart, yesterday morning. The animal was discovered by Sergeant G . Nicholson, of Glasgow Police, at present holidaying at Carty, Newton-Stewart, while out for a walk. Seeing the animal, with only the head, neck, and part of back visible, he ran for assistance to workmen at Carty Tileworks. Ropes and shovels were brought, and after some time the men were able to pass ropes underneath the body of the animal and haul it to safety. The mare was the property, of Mr Robert Currie, Moorpark of Barr, Newton-Stewart.

13/03/1943 – Dumfries and Galloway Standard – For sale, The old established brick and tile works known as Carty Brick and Tile Works situated about two miles from the Market Town of Newton-Stewart. The Works are fully equipped and are in active production. There are ample Clay Reserves of first-class quality, Works Railway Siding, Dwelling-Houses, etc. The Clay is suitable for Pottery. The Works are the only ones in Southern Scotland and have always been producing to full capacity. They have been carried on successfully for nearly 60 years by the present owner, who is retiring from business. For further particulars apply to David Breckenridge, Solicitor, Newton-Stewart.

1961 – 1962 – A directory of British clay products and manufacturers – Carty Tileworks. Head office c/o Allan Howie, Harbour Street, Ardrossan, Ayrshire. Tel – Ardrossan/Saltcoats 468. Works – Newton Stewart, Wigtownshire. Tel Newton Stewart 116. Agricultural drain tiles.

Below – A fantastic article on the Carty Tileworks as compiled by Craig Gordon for a school project in 1987.

Carty Tile Works

Carty tile works – (unknown date) Important little Galloway industry.

In A Pleasant Wilderness

DOWN by St. Ninian’s Creek where the River Cree idly meanders towards the sea lies Carty Port and the Tileworks. Mud stretches on either side of the river in thick, oozy banks and when the tide is out it glistens in the sun like the wet grey back of a seal. There grow long, golden rushes by the edge of the mud. The land on either side is an entanglement of wile plant life and when the wind blows, even gently, across the flats, the stillness is broken by thousands of whispers and rustlings in the undergrowth.

The low, long building of the Tileworks have rested a place for themselves amongst the pleasant wilderness by the river. They are unpretentious in style and look more like an aftermath of the war with their mission shapes. In front of them stands the kiln and its chimney, cracked with extreme temperatures, both hot and cold, and bound round with staunch iron bars. By the roadside lies the product of the works-bright red, brittle drainage tiles.

Damp Grey Avenue

The fired were black when I arrived there, but I could hear the busy noise of the machinery coming from the direction of the sheds. On entering one of the sheds I found myself amongst avenues of damp grey pipes and at the far end, I could see two men feeding clay into a mill which came out soft, pliable and even in texture. hey directed me towards the manager, Mr John Gordon, who was working with three other workers on a pipe-making machine.

“That’s Me”

I had to shout above the din to make myself heard. “Which is the manager please,” I asked. The man I directed the question at smiled and said “That’s me.” Mr John Gordon, manager of the Tile Works, a well-built man, good-natured man. He has a strong face, only slightly lined and friendly, smiling eyes. When he heard why I had dropped in he laughed, shook his finger at me and said, “Now, no names mentioned!” The others laughed.

Nothing Much

John gave instructions to one of the men then turned to me. “What do you want to know? there’s nothing much to see,” he said pleasantly. “How long have you been here?” I asked. “Oh, about thirty years or more,” he replied, and took in the scene around him contentedly. He continued. “They have been making tiles here for nearly one hundred years.” We were standing by the wall of red tiles and I asked, “How are these red tiles I asked, “How are these red and the ones in the shed grey?”

Yellow, Then Red

“Well,” John replied, drawing himself up. “First of all we use a yellow clay which we get from the field behind my house, This is milled to get an even texture, then is pressed through the moulds where you met me, and the tiles are placed n the shelves to dry. When they are dry enough they are fired in the kiln and turned out red during the heating.” “How do you know when they are dry enough to fire?” I asked. “You can tell by the colour of them,” he replied. “Any damp patches show up If you fire them when they are still damp when the frost has been at them they crack.” We walked across to the sheds and John took down a tile and showed me how the tell-tale damp patches showed up. “We close the sides of the sheds in the wintertime or when there is a frost,” he informed me. “Are these the heaters suspended from the roof?” “Yes,” he replied, “And they are very effective. You would be very surprised at the heat that comes off them.”

Matter Of Experience

A question had been running through my mind for some time and that was how Mr Gordon knew when the tiles were fired enough. Was there some kind of thermostatic control on the kiln that maintained the firs at a certain temperature, I asked him. He shook his head slowly and smiled. “No, no ; there’s nothing like that here. It’s a matter of experience I suppose. You just know when the tiles are ready. I’ve no idea what the temperature would be inside the kiln, but if one stands on top of it one can see all the tiles because they stand on their ends and, as I say, one just knows when they are ready!” Mr Gordon made it sound easy because to him, of course, it’s a task, but I believe it takes quite a while to expertly estimate what the correct temperature should be for firing. Many a shapely vessel had to be thrown away after hours of work because of the lack of experience in firing!

Efficient

“What kind of kiln is your one, John?” I asked “It works on a downdraft principle,” he said. “The heat rising to the top of the kiln and comes down through the tiles. It’s far more efficient than the old one. It saves us quite a bit in coal and about ten hours in firing time.” “How many tiles can you get in for one firing?” “About fourteen to fifteen thousand. It takes thirty-six hours to fire them. This is done once a week. Come and I’ll show you how the tiles are made.”

“Cheese Cutter”

We went into the shed where I first found John and where the clay was coming out of the moulds in three long lengths of piping. A giant “cheese cutter” made of piano strings cut the clay into four short sections and two men took them off the moleskin rollers with large, unwieldy, three-pronged, wooden forks and laid them on shelves to dry. “Have a shot yourself!” shouted John above the noise of the machinery, and one of the younger men offered me his fork. I almost dropped it immediately. The thing seemed to weigh a ton. I began to wonder how I would manage when I had a load of wet clay on the end! I went through the actions. I had watched and struggled with my load towards the lowest shelf I could find but nearly dropped the lot. The second effort landed the clay on the edge of the shelf and there it stuck like glue. One of the men came to my rescue and we got it shelved properly. John grinned, “It’s quite heavy!” he said. I gave him a spent nod. Just at that moment one of the men came along with a barrow loaded with blocks of clay for the machine.

The “Cart Horse”

“I’m just the “cart horse” around here,” he said with a laugh and the others joined him. “Like to try the barrow?” I complied and realised what he meant. He continued “Whatever you write he said, don’t forget the cart horse. He’s also important! “Aye, it’s good healthy work,” said John. “Our latest member tells me that he’s been eating twice as much since he came here.” I said my good-byes shortly after this and they all gave me a cheery wave-a happy group of workmates contented in their job of producing for near and far. Carty Tile Works doesn’t look much but it’s important: and what’s more important the men like their job.

Carty tile works 2

Below – examples of products believed to have been manufactured at the Carty Brick and Tile Works. They were found on site.

Below – 18 cored brick

Below – Drainage tile – 14½” x 3″

.

Below – Drainage tile – This tile is broken so the original length is unknown. Height 4″ x width 3¾” x base 2½”

.

Below – Drainage tile – 13″ x 3 1/4″. There is some unusual stippling on the outside of the tile – this resembles marks left by material or sacking perhaps.

.