General Refractories Limited, Sheffield, England and Scottish connections.

Below – 1930‘s – Advert for Dykehead firebricks as manufactured by General Refractories.

19/02/1937 – Western Mail – The refractories stand. Many orders expected at Birmingham The importance of refractory materials is well presented by the stand of the General Refractories Group at the British Industries Fair, Birmingham. The stand is one of the largest in the exhibition and the wide ramifications of the group are graphically represented by special maps. The design of the stand indicates the extent of the business which is expected. On top, there has been constructed a special room, in which orders can be transacted and which contains facilities for a dictaphone typist. Space is devoted to the products of various companies in the group. For instance, the Glenboig Union Fire Clay Company. Ltd. (Lanarkshire), has a large. section, in which are exhibited firebricks from several of the Scottish interests. The stand carries comprehensive displays of heat resisting and heat insulating materials. Conserving heat is one way in which the manufacturer can cut down expenses. It is certain that there will be many inquiries about the insulating firebricks on view. They save 8 per cent of waste heat and reduce fuel costs by 20 per cent. There is a striking display of the new Saxpyre product, an improved basic refractory, while there are important exhibits of moulding and silica sands.

Below – 23/07/1937 – South Yorkshire Times – Reference to Saxpyre bricks.

Firebricks:- Glenboig, White Carr, Castlecary, Gem, Stour, Gartcosh, Dykehead, Llagennech.

Insulating materials:- Fosalsil, Economite, Super and Insulite Bricks.

Silica bricks:- Meltham, Lowood, Allen and Bawtry Bricks.

Plastic refractories:- Durax No. 1, Durax No. 2, Pyrocrete, Rotaline, Glendoline.

Cements:- Sintex, Pyrolyte, Durax No. 3.

Sands:- Mintlyn, Somerford, Harperley, K.L. Silica, Bramcote, Zenith, etc., etc.

Below – 30/12/1937 – Sheffield Independent –

.

.

06/01/1939 – Western Mail – General Refractories scheme of consolidation. In accordance with the policy of consolidation which is now in progress the board of the General Refractories Ltd announces that certain subsidiary companies are being placed into voluntary liquidation for the purposes of amalgamation. The following companies are being liquidated for the purposes of amalgamation with General Refractories Ltd:- The Armitage Works Company Ltd, Henry Brooke and Co (Denholme) Limited, W. H. Girling and Co Limited, the Guiseley Silica Company Limited, the Midland Refractories Company Limited, the Weeland Sand Company Limited and the Ambergate Colliery Company Limited. In addition, the following companies are being liquidated for the purpose of amalgamation with the Glenboig Union Fireclay Company Ltd:-Castlecary Firebrick Company, Ltd., Faskine and Palacecraig Bricks and Coal, Ltd., and George Turnbull and Co., Ltd. Also South Wales Refractories, Ltd., is being liquidated for the purpose of amalgamation with N. B. Allen and Co., Ltd., which company, subject to the consent of the Board of Trade, proposes to change its name to N. B. Allen and South Wales Refractories, Ltd. The board considers that the scheme of consolidation now being carried into effect will result in considerable economies and will simplify control of the trading activities of the group.

Below – 04/1960 – Refractory Journal.

Below – 07/1960 – Refractory Journal.

1961 – 1962 – A directory of British clay products and manufacturers – General Refractories Ltd, Genefax House, Sheffield, 10 Yorks. Tel: Sheffield 31113. Works – Sandy Lane, Worksop, Notts. Basic Refractories – Wharncliffe Works, Deepcar, Sheffield. High Alumina Refractories – Lowood Works, Deepcar. Silica Refractories – Davison Works, Buckley, Chester. Acid Resising Refractories. Trade names ‘Alumantine’ – high alumina fire bricks; ‘Glenboig’ – Scottish fire bricks; ‘Sillmax’ – sillimanite bricks; ‘Davison’ acid resisting bricks; ‘Durax’ – refractory concretes.

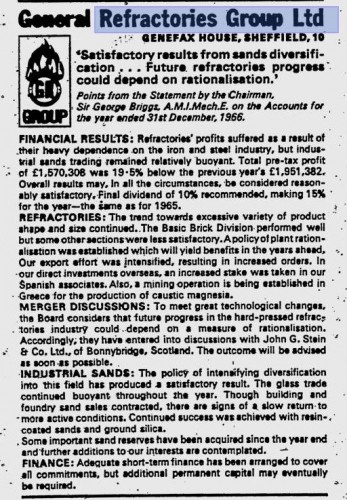

Below – 23/03/1967 – The Glasgow Herald.

Below – 08/1987 – The Refractories Journal –

*****************************

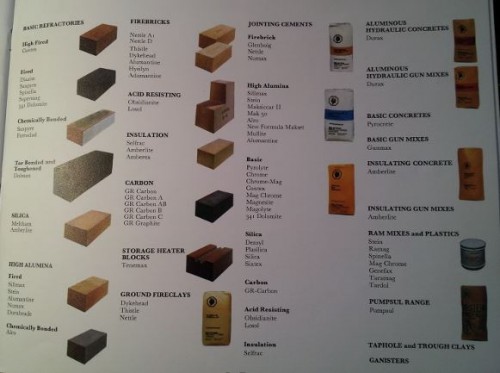

The following products are taken from a GR – Stein Refractories Ltd leaflet with an unknown date.

“Refractories for the lime industry”

Basic Refractories

Contex 60 – High fired magnesite chrome

Contex Msg CSD – High fired magnesite chrome

Spinella CN – Fired magnesite chrome

High Alumina Refractories

Numax – Aluminous firebrick

Stein 45D – Aluminous firebrick

Sillmax 55 – Fired high alumina

Sillmax 63 – Fired high alumina

Stein 63 – Fired high alumina

Stein 70D – Fired high alumina

Firebrick Refractories

Nettle D – Dense 42% alumina firebrick

Nettle A1 – Dense 42% alumina firebrick

Thistle – 35 – 372% alumina firebrick

Davison Refractories

(Note: – Davison’s specialised in refractory and acid-resistant bricks. Charles Davison’s Ewloe Barn Brick and Tile Works and Old Ewloe works were active from 1933 to 1951, and was later merged with General Refractories Ltd, and then taken over by the firm of G. R. Stein Ltd. The site closed in 1967.)

Alumantine 70/72 – Fired high alumina

Alumantine 60/65 – Fired high alumina

Alumantine 43/45 – Fired high alumina

Alumantine 40/43 – Fired high alumina

Hysilyn – Dense 28% alumina firebrick

Adamantine – Dense 25% alumina firebrick

Insulating firebrick

Selfrac 23 – Hot face insulating brick. ASTM C155 Group 23. 1260c

Insulation Refractories

Amberlite S43 – Solid grade Diatomic

Amberlite 43 – Solid grade Diatomic

Amberex HT – Calcium silicate ‘back up’ insulation

Jointing Cements

Pyrolyte cement – Basic jointing cement

Sillmax AS Cement – High alumina jointing cement

Stein High Alumina AS Cement – High alumina jointing cement

Maksiccar 11 Cement – Aluminous jointing cement

Selfrac AS Cement – Insulation jointing cement

Monolithic Refractories

Durax C1350 – Coarse-grained concrete

Durax C1600 – Coarse-grained low iron concrete

Durax AR GM – Abrasion-resistant gunning concrete

Durax 1700GM – High alumina gunning concrete

Durax BF Gun Mix – Low iron gunning concrete

Amberlite 50/GM – Lightweight insulating concrete

Amberlite 50P/GM – Lightweight gunning concrete

Amberlite 90 – Medium-weight insulation castable

Pumpsul VH35 – Lightweight insulating concrete for installation pumping

Stein 45 Plastic – Heat setting aluminous plastic

Stein 73 Plastic – Heat setting aluminous plastic

************************************

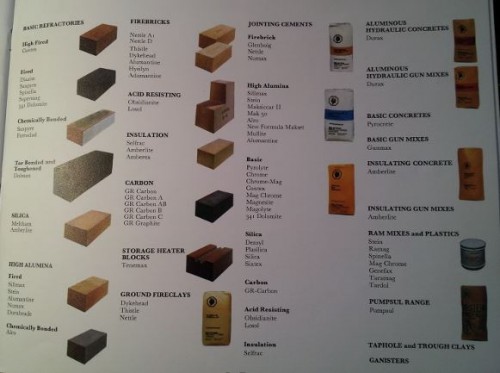

The following products are taken from a leaflet with an unknown date.

High Fired

Contex

Fired

Diazite

Saxpyre

Spinella

Supermag

341 Dolomite

Chemically Bonded

Saxpyre

Ferroclad

Tar Bonded and Toughened

Dolmax

Silica

Meltham

Amberlite

High Alumina

Sillmax

Stein

Alumantine

Numax

Durabrade

Chemically Bonded

Alro

Firebricks

Nettle A1

Nettle D

Thistle

Dykehead

Alumantine

Hysilyn

Adamantine

Acid Resisting

Obsidianite

Losol

Insulation

Selfrac

Amberlite

Amberex

Carbon

GR Carbon

GR Carbon A

GR Carbon AB

GR Carbon B

GR Carbon C

GR Graphite

Storage Heater Blocks

Tenemax

Ground Fireclays

Dykehead

Thistle

Nettle

Jointing Cements

Firebrick

Glenboig

Nettle

Thistle

High Alumina

Sillmax

Stein

Maksiccar II

Mak 50

Alro

New Formula Makset

Mullite

Alumantine

Basic

Pyrolyte

Chrome

Chrome – Mag

Contex

Mag Chrome

Magnesite

Magolyte

341 Dolomite

Silica

Densyl

Plasilica

Silica

Sintex

Carbon

GR Carbon

Acid Resisting

Obsidianite

Losol

Insulation

Selfrac

Aluminous Hydraulic Concretes

Durax

Aluminous Hydraulic Gun Mixes

Durax

Basic Concretes

Pyrocrete

Basic Gun Mixes

Gunmax

Insulating Concrete

Amberlite

Insulating Gun Mixes

Amberlite

Ram Mixes and Plastic

Stein

Ramag

Spinella

Mag Chrome

Genefax

Taramag

Tardol

Pumpsul Range

Pumpsul

Taphole and Trough Clays

Ganisters

********************

Below -Undated – Another little resume of the company from a brochure.

Manuel, Castlecary, Star and Chapelhall Works

Refractories play a vital part in heat-using industries all over the world. Key industries such as iron and steel, cement, glass, petrochemicals and power generation depend upon refractories for lining furnaces, which operate at temperatures up to 2000c.

To keep pace with rapidly changing industrial user technology, the refractories industry has deployed large capital investments in highly mechanised plant and machinery. Production methods have been streamlined with a precise degree of technical control never before achieved. Research and development facilities are able to withstand severe conditions such as chemical and slag attacks and thermal shock.

GR-Stein Refractories Limited (a member of the Hepworth Ceramics Group) is one of the world’s leading refractory manufacturers with 13 plants throughout the UK, making over 300 refractory products. Over 2,000 people work in the company’s Scottish works, which comprises four production plants – Manuel, Castlecary, Star and Chapelhall.

Manuel

Situated on an 87-acre site near Linlithgow, Manuel is one of the largest plants of its type in the works, with an annual production capacity of nearly 200,000 tons.

Manuel was built in 1928, primarily to manufacture a high-quality firebrick from a newly developed high-quality fireclay seam in the area. Today, the plant also manufactures large tonnage of high alumina and basic refractories, mostly from imported raw materials. Approximately 1,000 people at Manuel produce exports to 85 overseas countries.

Castlecary

The Castlecary plant is situated in the Central Scotland industrial belt between Edinburgh and Glasgow. Castlecary, like Manuel, is based on a local fireclay mine which provides the raw material for the production of firebricks, phosphate bonded refractories and a wide range of Tenemax domestic storage heater blocks.

(Harley Marshall, who used to work at the Castlecary works remembers storage and electric heater blocks being made for Electrolux, Elux and Belling and a heavy, high percentage iron content block called Feolite. All these blocks were marked with the customer’s name and not the manufacturer eg, not Stein etc). Kenneth Sanderson was at one point manager of the production of storage heater bricks. He also remembers Castlecary producing many fire bricks for use by the Kenyan Railways)

In addition, Castlecary manufactures refractory cements and monoliths, including mouldables, gun mixes, ram mixes and concretes.

Employing approximately 540 people Castlecary is the HQ of GR-Stein’s Scottish operations and handles all the company’s exports.

Star

Employing over 200 people, Star Works is situated at Glenboig, near Glasgow. Like Manuel and Castlecary, Star is based on a high-quality fireclay seam and produces a range of products that are complementary to Manuel and Castlecary’s output.

Chapelhall

Chapelhall Works near Airdrie has approximately 50 employees. It is a plant that makes a vitally important contribution to the Northern Division’s output, by manufacturing refractory bricks, castables and mouldables.

****************************************

Information from John Bramall regarding product pricing at Gr Stein.

It’s worth noting that GR-Stein UK prices were always £ per piece or £ per 1000 pieces usually delivered to UK site though the cheaper products (Scottish firebricks mainly but also some monolithic products too) were priced in relation to haulage distance – so Nettle D would be cheaper in Scotland than the Midlands and the Midlands were cheaper than the South East, Wales etc. I think there were about 6 delivery regional prices. Small lots, of say, 1 pallet would be sold as an ex-works packed price with haulage charges at cost on top.

Export prices were always £ per tonne. This is because sea (and air) freight is charged by weight.

So an export job might be quoted as £xxx per tonne, packed, ex-works plus shipping at cost. Sometimes GR-S would quote prices FOB UK port. FOB = Free On Board. So the overseas customer has to arrange and pay for sea freight costs with GR-S paying (but included in the price) for transport to the docks and cranage onto the designated ship. You can imagine that an overseas customer wouldn’t have a clue what the cost of haulage is inside the UK! For some export orders, there would be extra charges for crates as opposed to shrink-wrapped – depending upon destination and customer requirements. You’ve got to remember some goods were shipped to some 3rd world destinations e.g. Zambian copper mines, Chile likewise, sugar mills on tropical islands, new steelworks in jungles in Brazil.

When an order is received it goes through accounts/credit control to see if GR-S will accept the order or agree on other terms with the customer.

If it’s an export order there would normally have been a reference to an export credit insurer at the quotation stage and their cost would have been added into the quoted price – might add c. 5% to the prices. So when the order is received then GR-S would get the export insurers confirmation that the same terms (or other) apply. Remember it could be 6 months or more between tender and order.

At GR-S in 1975, it was all ‘mainframe’ computer order processing. So if you got the manually prepared quotation right and it was accepted by the customer then it was straight forward. Put the order on to the system as a ‘master’ document – that created an ‘Order Acknowledgment’ that went to the customer; a ‘works order’ that went to the works; office copies to the head office sales office, regional sales office and a copy to the order progress section at Head Office. So everyone knew what was on order, when it was due for delivery and allowed the order progress people to check it got made on time.

As products were made, packed and cleared for shipping a new set of documents was created based on the original computer docs to cover haulage, invoicing and accounts.

It was all very efficient.

UK sales were usually on open account – pay after 30 or 60 days from date of despatch or cash before despatch if a new customer or poor credit record.

The hard part was getting the enquiries; pricing up the jobs from drawings; winning the tenders; getting the products made on time and shipped out, then, getting paid!

Below – These insulation bricks were found at the Manuel Works by Ian Suddaby. Selfrac Plus, Super and Solid Fosalsil. They are all listed as General Refractories products. Ex workers at Manuel remember only the Selfrac bricks being made there. They believe the Super and Fosalsil were brought up from England.

Below – 27/08/2023 – Manuel Brickworks, Whitecross – Photos by Ian Suddaby. Groundworks on the site revealed some old plastic buckets of Makset.

.

Below – Label ‘Makset 301’ found at the Manuel Brickworks by Ian Suddaby.