Canmore

Below – Glasgow Iron and Steel Co – Source

Glasgow Iron and Steel Co of Wishaw – 1844 Company established.

1853 – The Glasgow Iron Co acquired the derelict works at Motherwell of the West of Scotland Malleable Steel Co for £42,050. The works were managed by Thomas Martin, who improved, and patented, the refining and puddling of iron.

1864 – Wishaw Iron Works were taken over by the Glasgow Iron Co, from St Rollox, who also operated a malleable ironworks in Milton Street, Motherwell.

1888 – Incorporated as Glasgow Iron and Steel Co.

Appointed Thomas Williamson as engineer and manager.

1894 – The works were converted to open-hearth steel making.

1895 – James Riley appointed as the general manager of the company’s collieries, blast furnaces, malleable-iron works and steelworks. Riley was a leader in the evolution from malleable iron to steel.

1895 – The works were the first to use a gas engine to generate power for lighting and the rolling mills, driven by blast furnace gas, from Lamberton and Co in Coatbridge.

1900 – Announcement of two new melting furnaces. Also mention that Mr Riley left, having purchased the Richmond Ironworks at Stockton-on-Tees.

1902 – The Motherwell works were closed.

1914 – Steel manufacturers, coalmasters. Specialities: steel plates for ships and boilers; patent interlocking steel piling, bars, angles, channels, billets and slabs; sulphate of ammonia, oil, pitch and tar.

1920 – Beardmores joined with Swan, Hunter and Wigham Richardson of Tyneside to acquire the Glasgow Iron and Steel Co. However, a general trade depression followed exacerbating the overcapacity in the steel industry, and the plant made losses in 1921 and 1922. This was at a time when Beardmore’s had expanded their Mossend Steel Works. The steel plant at Wishaw was closed and eventually dismantled. The blast furnaces at Wishaw remained in operation and made a profit until 1927 when they also went into loss and were closed in 1930.

1947 – Beardmores sold its remaining interests in the Glasgow Iron and Steel Co to Lithgows

1952 – The company commissioned and built the Mayfield brickwork in Carluke.

**********************************

History 1844 – 1976 – Although Glasgow Iron and Steel Company was registered as a limited company in 1888, it first traded as c company in 1844. The basis of the company was, as its name suggests, iron and steel and records show that it is apparently operated from time to time a number of foundries and ironworks in West Central Scotland and it is known that in 1899 the company had 8 working coal and ironstone mines. It also diversified in 1914 to become the largest producer of cement in Scotland and it was at this time that the trade name of GISCOL was established.

The remnants of the iron and steelworks were eventually lost to the company in 1947/48 (nationalisation), the mines being closed some years earlier.

13/12/1884 – Wishaw Press – John Murphy and Wm. Handy, miners and James Wheelan, labourer and Win. Johnston, blacksmith, all with no fixed residence, were fined 15s or 10 days imprisonment for lodging in the Glasgow Iron Company’s Brickwork on Tuesday morning without leave of the owner. (Note – SBH – I am uncertain as to which exact brickworks this relates to).

06/03/1886 – Wishaw Press – Lodging in a brickwork. Thomas Burns, labourer with no fixed residence, pleaded guilty to a charge of lodging in the brickwork at the Glasgow Iron Company’s No. 7 Pit, without leave of the owners, last Sunday night, and was fined 7s 6d or 5 days’ imprisonment. (Note – SBH – I am uncertain as to which exact brickworks this relates to).

22/04/1893 – Wishaw Press – Article regarding a serious assault in the vicinity of the Glasgow Iron and Steel Co’s No 7 Brickwork near the South Station, Wishaw … (Note SBH

30/09/1893 – Wishaw Press – Burning accident. On Saturday morning, a miner named Wm. Horn (44) with no fixed residence, was severely burned at No. 7 Brickwork, belonging to the Glasgow Iron and Steel Company. He had been sleeping about the stoves and it is supposed that some ashes had fallen out and set his clothes on fire. While a police officer was on his way towards the South Station, Horn cane running out crying that he was burning. The constable at once put his cape around him and extinguished the flames. Dr Duff was sent for and attended to the injuries, and found that the man had been severely burned about the arms and side. He was sent by ambulance waggon to the Glasgow Royal Infirmary. (Note – SBH – I am uncertain as to which exact brickworks this relates to).

1931 – The company was owned jointly by Swan Hunter and Lithgows Limited who as shipbuilders wished to ensure a supply of steel sheet for the new generation of vessels.

Glasgow Iron and Steels’s first venture in brickmaking was in 1952 when it commissioned and built the present Birkfield Brickworks in Carluke and this was consolidated in 1954 with the purchase of the Motherwell Brick Company Limited. Nevertheless, brickmaking remained an ancillary part of the company operations until 1976.

Below – 23/05/1969 – Wishaw Press – GISCOL advert.

03/07/1970 – Wishaw Press – Glasgow Iron and Steel Company Ltd, Kiln emptiers, Experienced men required for brickworks in Carluke area Good wages and production bonus in operation. Apply to the Manager, Birkfield Manager, Boghall Road, Carluke.

Below – 04/07/1969 – Wishaw Press – GISCOL advert.

1976 – Separate brickmaking division established. Capacity 18 million common bricks per annum (4.9% of the Scottish market). Iain Irvine sales manager.

1980 – Purchased 7 million tons of potential raw material in Ayrshire (A Kenneth & Sons Ltd). Market share 7.3%

1982 – Lithgows acquired 100% control of the company. Board adopted a policy of positive expansion.

1983 – Company purchased Etna Brickworks from Steetley Brick Co Ltd (capital cost recovered within 8 months). Market share 20.1 %

1984 – Company purchased a further 7 works from the Scottish Brick Corporation. Market share now 70% of the Scottish market. Company 6th largest producer in the UK.

1985 – After initial contact with Proctor & Lavender, the company sells first facing bricks in England. Identified and secured new sources of raw material.

During 1985 1986 the company completed detailed research into the UK market. As a result, the board of GISCOL are committed to a policy of expanding both its own capacity and its range of facing bricks.

In addition to the mainstream brickmaking, GISCOL has additional interests in landfill, coal recovery and opencast mining.

Source GISCOL bricks brochure dated 22/10/1986.

At this time the director were

C H Parker – Chairman, Non-executive

JC Workman JP – Managing Director

I P Irvine – Director Sales

R A Thomson – Director of Production

D P Harvie CA – Director of Finance

Sir Michael Nairn Bt – Non-Executive

GISCOL (registered as a company in 1888) was the trading name of the Glasgow Iron & Steel Company Limited, an iron and steel producer with foundries and ironworks situated in West Central Scotland.

As part of this work, the company sunk pits at Machrihanish in 1946, which eventually became the Argyll Colliery, though the coal industry was nationalized before GISCOL could take control of production.

In 1952, the company commissioned and built the Mayfield Brickwork in Carluke. In 1983 Giscol added the Etna Works (established in 1897) to its portfolio and ran both together until a management buy out in 1997 saw the formation of Caradale Traditional Bricks. By the mid-1980s the oldest kilns at Etna had been demolished.

Caradale currently operates like a traditional brickmaking company using shale clay in the traditional manner at Etna and Mayfield, though it no longer has any connection with other industrial work.

25/05/1934 – Motherwell Times – We are glad to hear that Range Road (Grange Road?) District (Motherwell) is taking on signs of life again after a long season of stagnation. The tradesmen have made a start with the new brickworks in which the officials and shareholders of the Glasgow Iron and Steel Company Limited are said to be chiefly interested. The new Company have a large supply of clay and no end of blaes heaps at their disposal, out of which they hope to make an excellent composition brick and put it on the market at an early date. Close by the brickwork of Messr’s Wilson and Clyde and the Coltness Companies betwixt them have obtained part of the Motherwell Waggon Works which they intend to utilise for the repairing and perhaps manufacturing of all the waggons in their respective services. I understand that the surplus ground is to revert back to the superior by arrangement betwixt him and the liquidator of the defunct Motherwell Waggon Company, but it is gratifying to know that, through the new brickwork and the partial opening of the Motherwell Waggon Work, a measure of prosperity is returning to Range Road area.

Below – 08/04/1949 – Motherwell Times. GISCOL open a new brickworks in Carluke.

.

.

Below – 22/04/1949 – Giscol open a new brickworks at Boghall Road, Carluke.

Below – 28/07/1977 – The Glasgow Herald – GISOCL and MBC (Motherwell Brick Company) advert – “In with the bricks”

Below – 06/05/1983 – The Glasgow Herald – GISCOL buy Steetley Brick at Armadale.

Below – 27/11/1984– Glasgow Herald – GISCOL advert – Note trademark design.

17/01/1986 – Irvine Herald – More than £100,000 has been invested in the past year on new plant and machinery to upgrade Giscol Bricks existing works in Ayrshire. The brickworks are Pitcon and Broadlie at Dairy and Annandale at Kilmarnock. A substantial market for facing bricks has been developed from the Annandale works with many orders coming from the north of England and more recently bricks have been supplied to a number of sites in the London area Southampton and Bournemouth. The development at Annandale is expected to ensure a secure future for the works and continuing employment for the 120 staff of a staff throughout Ayrshire. In addition to facing bricks to England, Giscol are also supplying common bricks from their Dalry plants to the Liverpool-Manchester area where they are being used to blend with existing buildings. It is intended to develop the Pitcon works to fully exploit this potential market. Giscol have spent a further £25,000 in providing access to a bing at Lamridden in North Ayrshire. The bing has 30 years of material which will be used to produce the traditional Ayrshire clay common brick, for example, well fired, sharp arrises and good colour The investment in the bing is all part of the process of upgrading the quality of products from Giscol’s three Ayrshire works. Production of bricks by Giscol is now considered of such quality that they were used in the restoration of property in Ayr where bricks of a certain specification were necessary. Pitcon were able to provide old imperial-sized bricks to closely match the rest of the development. With a quality local product available Giscol are disappointed that local authorities in Ayrshire have in the past 10 years used materials manufactured outside the area. An information drive will be mounted to make Cunninghame District Council, Kilmarnock and Loudoun District Council, Kyle and Carrick District Council and other Strathclyde Region offices aware of developments at Giscol.

17/01/1986 – Irvine Herald – Sound foundation. Giscol Bricks – Glasgow Iron and Steel (Brick) Ltd were established in 1840 and involved in the past in steel, cement and mining. Expansion into the brick industry came in 1981 when an old established Dreghom company, A Kenneth and Sons was bought over providing access to a substantial amount of raw materials. Further expansion followed in 1984 with the acquisition of Scottish Brick and this move meant Giscol were the only clay common brick manufacturers in Ayrshire. Giscol’s local sales office for Ayrshire is in Kilmarnock and enquiries should be made to Agnes Beaton on 056320316.

Giscol Brick and A. Kenneth & Sons Ltd are continuing to invest in Ayrshire.

Below – 17/01/1986 – Irvine Herald – And now a big hand for bricks! They always get a good reception. Rain, hail or shine you can depend on bricks – GISCOL bricks …

Below – 27/05/1988 – Glasgow Herald – GISCOL advert – Note trademark design.

Below – 16/02/1989 – The Glasgow Herald – The history of GISCOL.

16/02/1989 – The Glasgow Herald – Bricks for facing up to the rigours of climate – Giscol Bricks, the largest privately-owned brick making company in Britain, has produced a special range of high quality facing bricks custom-built to withstand the rigours of the Scottish climate. The Abbotsford Collection reflects the Glasgow Iron and Steel Company Ltd’s Scottish heritage with names such as Glendevon Buff, Braemar Mixture, Kirkfield Red Mixture, Atholl Buff Rustic, Drummond Red Rustic and Rannoch Brindle in its portfolio. They are made from top-quality materials in an eye-catching range of colours and textures, are low in soluble salts and frost resistant to BS3921: 1985 in accord with British Ceramic Research Laboratory and other accredited lab tests. Their design consciousness ensures that brick specifiers’ requirements can be matched. Part of the Lithgow Group, Giscol has had its former iron and steel activities superseded completely by brick making in recent years. Since 1982 it has been concentrating its resources to this end by way of strategic acquisitions in the industry. It has also embarked upon a major investment programme of approximately £2m which has added significantly to the brick making capacity of the company’s seven-plant production in Scotland.

A major part of the investment has gone into two ceramic fibre-lined kilns – the most advanced of their kind in the UK – in operation at Giscol’s Armadale and Edinburgh plants. They are being used to produce the Abbotsford Collection of facers, giving Giscol the most comprehensive range of bricks manufactured north of the Border. Facing brick has undergone a revolution in Scotland as architects and designers have acknowledged that their new building often lose their surface sheen within a few months of completion due to the extreme weather conditions experienced and most of the growing demand for facings is coming from the Central Belt. Today’s preference for facing brick can be traced back to a reaction to the drab, industrialised precast concrete finishes used in the comprehensive development areas of the 1960s. Because of the company’s vision, Giscol is benefiting from the increasing desire of Scottish architects and contractors to use quality building products manufactured in Scotland and the resulting rise in sale/production serves to complement their high volume sales down south.

Scotland sends some 70 million facing bricks to the southern market where they are eagerly sought after for their high quality while 100 million facers come back across the border to feed the current Scottish building boom. Giscol’s avowed aim is to capture a substantial slice of the expanding home market and the versatility of its new advanced kilns means a greater control of firing temperatures and kiln atmosphere leading most importantly to speed of production.

As Giscol’s chief executive and former production director Alister Thomson put it: “We have developed a wide range of facing bricks and are in the number one position in Scotland for the complete range of commons, engineering bricks and facers. Giscol is increasing its brick making capacity to match increasing demand and the company is ready through substantial investment and greater quality control to ward off the threat posed by imports from abroad when the Single European Market comes into force in 1992.” While Scotland is no longer seen as just a stone and render country Giscol is set fair for an increased expansion of business in the quality facings quarter. Brick faced buildings are back in popularity with local authorities and housing associations as there is a marked swing away from rendered structures. Brick is conducive to a warmer look and is used creatively to give a building a more individual stamp.

The Scottish Special Housing Association’s Gear project in Glasgow’s East End is a classic example of the intelligent use of facing brick to blend in with community characteristics without institutional uniformity. The correct choice of brick for a particular location is all important and Giscol’s all-Scottish Abbotsford Collection makes the architect’s task easier. Facing bricks add a decorative dimension to the exterior of a building and greatly enhance its appearance at a minimal cost. Made in Scotland from Scottish clay too much stricter technical standards for the more demanding environment of the Scottish market the Abbotsford collection with its smooth and rustic faces and rich colours are adaptable to many a feature finish in the arts and crafts tradition where the warm tones of the brick accentuate the architect’s lines.

**************

Further expansion in the pipeline – The anagram of the Glasgow Iron and Steel Company Limited is Giscol and the 100-year-old company refurbished its image in 1982 to concentrate on brick manufacture in Scotland. Today Giscol Bricks hold the Scottish number one position in volume terms and its Abbotsford Collection of facing bricks it is distinguished one with a fine pedigree. Giscol is the principal Scottish supplier of quality facing bricks due to its expertise and sophisticated kilns at Edinburgh and Armadale and 60 million facers are produced every year.

The Glasgow Iron and Steel Company was registered as a limited company in 1888 and as the name suggests its main activities were iron and steel. It operated a number of foundries and ironworks in West-central Scotland, had coal and ironstone mining interests and by 1914 it had become the largest producer of cement north of the Border into the bargain.

The trade name Giscol was established at that time. Between the wars the company was owned jointly by Swan Hunter and Lithgows Ltd, who wanted to ensure a steady supply of sheet steel for their shipyards. In 1982 Lithgows gained 100% control and the board adopted a positive policy of expansion with brick making as its prime objective. Throughout its 100-year history, Giscol (the Glasgow Iron and Steel Company Ltd), has played an important role in Scotland’s economic and industrial life. Its expansion into brickmaking helped to ensure that the Scottish industry would make a come back after the decline in the 1970s due to the cutback in public sector housing and the company’s recent investment of £2m on plant and equipment is already paying dividends. The myth has been exploded that Scotland cannot manufacture good facing bricks as the growing demand for Giscol’s Abbotsford Collection clearly shows.

Since 1982 the facing brick revolution in Scotland has shown a market sector increase of over 600% and streamlining and additional investment over the past few years have meant that he Scottish brick-making industry as a whole is capable of meeting all Scottish requirements. According to a Giscol spokesman: “The industry is healthy and expanding. Giscol, for example, has invested in the latest gas-fired kilns and always on the lookout for improvements we are experimenting with new methods and finishes. Many individuals together with their professional advisors are rediscovering the beauty, versatility and economy of using dependable bricks. We are geared to planned deliveries and quality control which will ensure that contracts both large and small will run in time.”

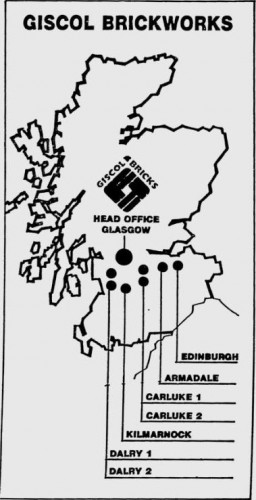

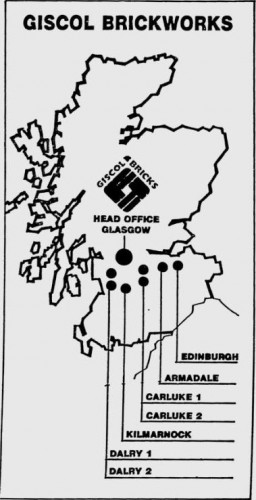

Giscol has currently seven plants in operation throughout central Scotland at Edinburgh, Armadale, Kilmarnock and two each in Carluke and Dalry, employing a total of 400 people in brick manufacture. Further expansion is planned. From its Glasgow sales office at Bergius House, Clifton Street, near Charing Cross, Giscol’s sales force covers every Scottish region, with a technical backup service available on request. Giscol is proud of its reputation in the booming Scottish facing-brick field in general and its multi-face Abbotsford Collection in particular.

*************************

Source – Tilcon coloured mortar, brick and block directory 1989.

Giscol bricks – Bergius House, 20 Clifton Street, Glasgow G3 7XS

Clay bricks.

Abbotsford collection.

Glendevon Buff, Atholl Buff Rustic, Kirkfield red mixture, Drummond red rustic, Braemar mixture, Rannoch brindle, Thornton buff, Barnton buff, Melrose buff.

Sole distributor in England Proctor & Lavender Limited, Bridge Estate, Lode Lane, Solihull, West Midlands. B91 2HB

Clay bricks

Giscol Range – Waverley blend, Glendale smooth, Lothian drag wire, Lothian rustic, Pentland buff, Royal mixture, Border mixture.

***************************

Below – GISCOL Birkfield sign rescued by GK

*************************************************

22/04/1997 – The Herald Scotland – Brickworks fined – A brickworks was fined £1000 yesterday after bosses admitted allowing sulphur dioxide to leak into the atmosphere at the Etna Brickworks in Armadale, West Lothian, which is owned by Glasgow Iron and Steel Co Ltd, of Clifton Street, Glasgow.

*************************************************