Gartcosh brick found in Sri Lanka

— 11/02/2025This brick was photographed by Siobhan Ratchford at the The Queens Hotel, Kandy, Sri Lanka. Gartcosh Fireclay Works, Gartcosh, Glasgow. . . . .

The Glenboig Star Fire Brick Works and the Glenboig Fireclay Works joined to form the Glenboig Union Fireclay Company, Glenboig which by the end of the 19th century was reputed to be the largest fireclay company in the world.

******************************************************

Robert Hillcoate is known to have been working the fireclays in Glenboig beginning in 1836. By 1843 Hillcoate was gone and John Thomson was managing director of Glenboig Firebrick & Tile Works. In 1858 James Dunnachie joined the company as secretary and salesman. In 1860 Thomson was joined by Richard Smith and Charles McLean as partners in Thomson, McLean & Company.

Dunnachie persuaded John Hurll and John Young to join him after the death of Smith in 1865 and The Glenboig Fire Clay Company was formed. The partnership was broken up in 1873 when Dunnachie left to build the Glenboig Star Works (see below), John Young left to concentrate on his Heathfield and Cardowan interests and John Hurll stayed on at Glenboig.

1836 – Robert Hillcoate is known to have been working the fireclays in Glenboig, beginning in 1836.

1841 – 1842 – Hillcoate & Thomson, fire brickworks, Glenboig, Monkland and Kirkintilloch Railway, store Garnkirk and Glasgow railway, Townhead. Orders left at A. & J. Nisbet’s, ironmongers, 100 Trongate.

1843 – 1844 – Glenboig Fire Brick Work. P W Dixon, Agent, 107 Buchannan Street, Glasgow. Store Garnkirk and Glasgow Railway Depot, Townhead. Orders left at A & J Nisbet, 100 – 102 Trongate.

1843 – 1844 – John Thomson, Fire brick maker, Glenboig Store, Garnkirk Railway Depot, Townhead. Orders left at 100 – 102 Trongate.

1846 – 1847 – John Thomson, fire-brick maker, Glenboig, parish of New Monkland. Orders left at A. & J. Nisbet’s, 100 and 102 Trongate.

04/09/1846 – Glasgow Herald – Labourers wanted – apply Glenboig Fire Brick Works, Garnqueen Station.

31/08/1847 – Greenock Advertiser – On Saturday last, while a young man named Thomson was superintending the blasting of fire clay at Glenboig fire brick and tile works, an explosion took place by which he was thrown upwards of 50 feet into the air and fell amongst a heap of stones. The youth had been dreadfully burned in the face and has had one of his legs broken and has altogether sustained such severe injuries that his life is despaired of.

1849 – 1850 – John Thomson, Glenboig Fire Brick Works. Orders left at 180 Trongate.

1849 – 1850 – Glenboig Fire Brick and Tile Work. Orders left at A. Nisbets 180 Trongate, Glasgow.

24/05/1850 – Glasgow Herald – The subscribers pay their labourers their wages daily if required. John Thomson & Co. Glenboig Fire Brick Works. 22/05/1850.

21/06/1850 – Glasgow Herald – Death – At Glasgow – on the 15th, of consumption, Anna Hillcoate, teacher, Lochranza, Isle of Arran, daughter of the late Mr Nichol Hillcoate, bricklayer and brick manufacturer of Gartsherrie and Glenboig.

06/09/1850 – Glasgow Herald – The co-partnership carried on by the subscribers as sole partners under the firm of John Thomson & Co, fire brick and tile makers at Glenboig, in the Parish of New Monkland, has been dissolved on this date by mutual consent. The debts due by the Company will be liquidated and the debts due to the Company will be uplifted and discharged by the subscriber, Mr Thomson. Glasgow 04/09/1850 – Thomas Hill (Hillcoate?) and John Thomson. Witnesses – James Keyden and Adam Paterson.

14/10/1851 – Greenock Advertiser – Deaths – At Milton Street, Glasgow on the 12th inst, of consumption of the lungs, Mr Nichol Hillcoate, son of the late Nichol Hillcoate Esq, bricklayer and manufacturer of bricks at Gartsherrie and Glenboig.

Below – 1852 – Advert for John Thomson and Co, Glenboig.

1853 – Imported brands continued to be preferred even though local fire bricks were being made by this time. In 1853 ten thousand fire bricks were imported for use in the Sydney Mint, Australia where there were a number of furnaces and boilers, and these were branded: Upward arc of lettering STAR WORKS J [six-pointed star] D GLENBOIG

James Donnachie manufactured these at the Glenboig Star Fire Brick Works near Glasgow, and he claimed to be the sole manufacturer of bricks for the Siemens furnace. They were shown at Sydney in 1879 and Melbourne in 1880. In 1888 – 1889 fire bricks were shown at Melbourne by what must have been a descendant or related company, the Glenboig Union Fire Clay Co Limited of Glasgow.

12/01/1855 – Glasgow Herald – Royal Patriotic Fund, Lanarkshire – Contributors – John Thomson & Co Glenboig.

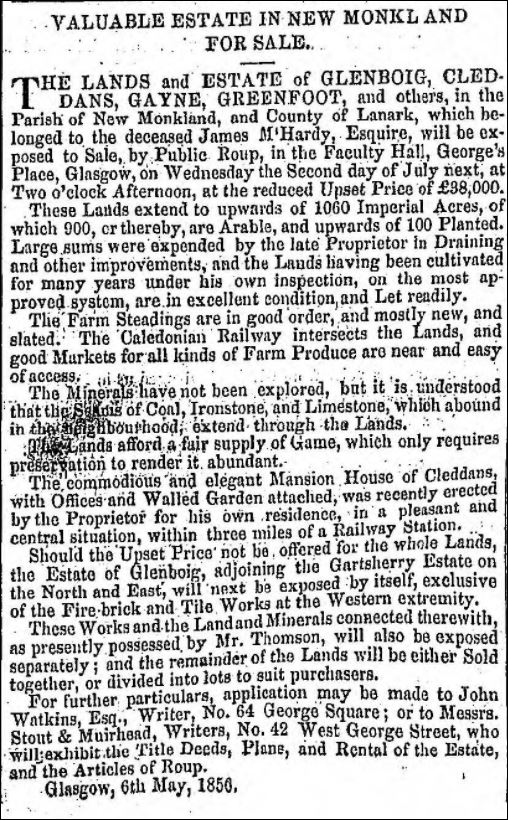

04/06/1856 – Glasgow Herald – The Estate of Glenboig for sale. Also references the Glenboig Firebrick and tile works possessed by Mr Thomson which will be exposed for sale separately. Glasgow 06/05/1856.

Below – 11/06/1856 – Glasgow Herald – The lands and estate of Glenboig, Cleddans, Gayne, Greenfoot and others in the Parish of New Monkland which belonged to the deceased James McHardy esquire will be exposed for sale … Should the upset price not be offered for the whole of the lands, the Estate of Glenboig, adjoining the Gartsherry Estate on the North and East will next be exposed by itself, exclusive of the fire Brick and Tile Works on the Western extremity. These works and the land and minerals connected therewith are presently possessed by Mr Thomson, will also be exposed separately …

c. 1858 – James Dunnachie joins the company as a bookkeeper and traveller.

1858 – Mineral Statistics of the United Kingdom of Great Britain and Ireland for 1858 – Glenboig, clay of coal measures. Name of freeholder – Patrick Rankine Esq. Manufacturer – John Thompson. Manufacture – Bricks, covers, flooring tiles and blocks. Estimated 3,880 tons annually.

Below – 1858 – Glenboig Firebrick Works.

Below – 1858 – Glenboig Firebrick Works.

1858 – 1861 – ScotlandsPlaces – Glenboig Fire Brick Works. John Thomson Esqr. Tolerably sized Fire Brick Works situated at the northwestern extremity of the Parish. The property of John Thomson Esqr.

1860 – John Thompson is joined by Richard Smith and Charles Mclean under the partnership name of Thompson McLean and Co.

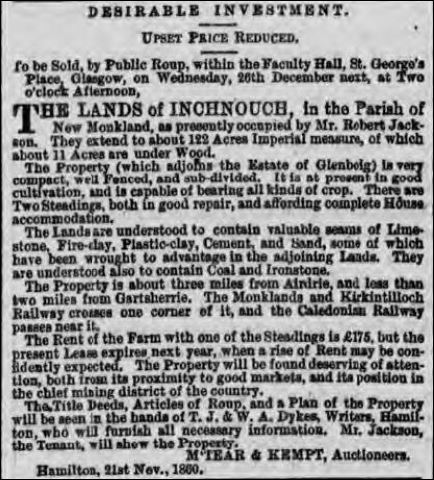

Below – 14/12/1860 – Glasgow Herald – Advert for sale of lands at Inchnouch, adjoining the Estate of Glenboig. The lands are understood to contain fire clay and plastic clay, cement and sand, some of which have been wrought to advantage in the adjoining lands …

02/08/1861 – Glasgow Herald – Reference to Mr James Thomson (not John ?), Glenboig Fireclay Works being available to show potential tenants around the adjoining Inchnouch Farm, New Monkland.

1861 – 1862 – Thomson, McLean, & Co., fireclay manufacturers, Glenboig, by Coatbridge, 49 West George Street.

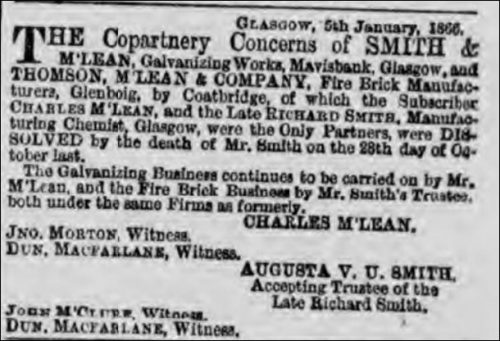

1865 – Richard Smith of Thompson McLean and Co. dies and the company dissolves.

1865 – James Dunnachie takes over the company and forms the Glenboig Fire-clay Co with John Hurll and John Young, themselves pioneer firebrick manufacturers. They pay £5,000 for the works.

Below – 06/01/1866 – Glasgow Herald – Thomson, McLean & Co, Fire brick manufacturers, Glenboig of which Charles McLean and the Late Robert Smith were partners has been dissolved on the death of Smith (28/10/1865). Mr Smiths’ trustees will carry on the brick business. Mr McLean has left the brick business to continue other interests.

20/01/1866 – Perrys Bankrupt Gazette – Scotch partnership dissolved – Charles McLean and Augusta V. A Smith, deceased, fire brick manufacturers, Glenboig, near Coatbridge and Glasgow, 23rd Oct.

25/05/1871 – Greenock Telegraph – Mad freak – Early on Tuesday morning a fearful explosion of gunpowder, resulting from the freak of a collier, occurred at Inchneuk Cottages, Glenboig Brickworks, by Coatbridge. A miner named Stewart McCandlish occupied one of the cottages, in which there resided, besides himself and wife, two lodgers named William Beckett and Francis McMahon. On Monday McCandlish and the two lodgers had been indulging in a carouse, which was prolonged till about one o’clock Tuesday morning, the three men sitting the fire with bottles and glasses drinking and joking. The fire, having become low, McCandlish took a cask of powder which kept for use in blasting, and taking it below his arm, commenced throwing handfuls of powder from the cask into the fire. Ere long the powder ignited, and a fearful explosion ensued. The house was broken to pieces, the door being broken into splinters, and the three men much injured. The two lodgers, Beckett and McMahon, who had remained sitting at the fire while McCandlish threw in the powder, were severely cut and burned about their heads and arms; while McCandlish was blown completely out of the house some distance. When picked up, it was found that he was also dangerously hurt; but providentially Mrs McCandlish, who was in bed at the time, escaped without the slightest injury. James Donnachie, Esq, of the Glenboig Works, who was at once sent for, bestowed every attention on the injured men and sent for Dr Murray of Muirhead. On the doctor’s arrival, he ordered the removal of the three men to the Glasgow Royal Infirmary, and a conveyance being kindly granted for that purpose by Mr Donnachie, Beckett and McMahon were removed without delay. McCandlish, however, would not allow himself to be taken. The whole of the men remain in a very precarious condition, little hope is entertained of their recovery.

1872 – When the Dunnachie, Hurll and Young partnership folded in 1872, Dunnachie built the Star Works immediately adjacent to the Old Works, and in competition with them. His bricks, at that time, bore the legend J. D. and the title “Star Works, Glenboig” or “Glenboig” with a star imprinted below the word. Hurll and Young went off and started the Cardowan Fireclay Company together and took over the Heathfield Brickworks which had started c. 1833.

1872 – 1873 – James Dunnachie (of the Glenboig Fire Clay Co.) Glenboig Cottage, near Coatbridge.

Below – 26/12/1873 – Edinburgh Gazette – Glenboig Fire Clay Co taken over by John Hurll.

03/05/1878 – Aberdeen Press and Journal – Paris Exhibition. Exhibitors – James Dunnachie, fire clay manufacturer, Glenboig Star Firebrick Works – fire bricks as used in the Seimens’ furnace, forge, rolling mill, puddling and all other descriptions of furnaces subjected to the most intense heats and sudden changes in temperature; glasshouse blocks; fire clay tuyeres used in the Bessemer steel process; and samples of Glenboig star fire clay; Hislop’s built gas retort …

05/04/1878 – The Scotsman – Paris Exhibition – The following Scottish Companies will contribute – … The Glenboig Fireclay Company, Coatbridge send samples of brick specially adapted for resisting the most intense heat. These bricks are largely used in the iron, steel and chemical works of Newcastle, Cleveland and West Cumberland districts while more than a million are forwarded yearly to Germany, Russia and Belgium. The fireclay used in them is, in point of geological position, the lowest known in the Lanarkshire carboniferous formation being at Palace Craig 700 yards below the surface, though owing to some upheaval it is worked at Glenboig at a depth of 40 yards …

10/09/1878 – Glasgow Herald – Paris Exhibition – In class 66 (Architectural and building materials) the Glenboig Fire Clay Company, 68 Bath Street, Glasgow are to receive a silver medal. Mr James Dunnachie, Glenboig Star Fire Brick Works, 2 West Regent Street is awarded 2 silver medals – 1 in class 66 and the other in class 43(metals and refractory materials) including tuyeres, runners, plugs, stoppers, etc for use in Bessemer & Siemens Steel processes.

17/10/1879 – The Argus, Melbourne – Alex Sutherland and Co are selling Glenboig Star firebricks.

26/02/1880 – The Sydney Morning Herald, NSW – Scott Henderson & Co agents for Glenboig Star firebricks.

25/05/1880 – Greenock Advertiser – Honours to Scottish exhibitors – James Dunnachie, Star Fire Clay Works – Refractory fire bricks, gas retorts, etc.

23/04/1881 – Lanarkshire Upper Ward Examiner – Explosion in a clay pit. On Thursday forenoon a miner named Robert Armstrongresiding at Glenboig got himself rather severely Robert Armstrong burned by an explosion of gunpowder which occurred when he was at work in a clay pit at the Star Fire Clay Works, Glenboig belonging to James Dunnachie. Armstrong had been in the act of tilling a charge of gunpowder for the purpose of firing a shot when a spark fell from the lamp which he had in his cap, amongst some loose gunpowder he had in his hand. An explosion ensued and he was burned pretty severely about the face. Dr Murray, Muirhead attended upon the sufferer and is of the opinion that no fatal issue is at present impending.

28/05/1881 – Invoice – Glenboig Fire Clay Company, Glenboig Fire Brick Works near Coatbridge. Depot, Head of Glebe Street, St Rollox, Glasgow. Office, 68 Bath Street, Glasgow. Fire bricks, sewerage pipes, chimney cans, silver sand.

28/05/1881 – Dundee Courier – Prosecution under the factory Act. Employer fined £70. On Thursday before Sheriff Mair at the Airdrie Sheriff Court, John Hurll, proprietor of the Glenboig Fire Clay Works was brought up at the instance of Mr Strokes, H.M. Inspector of Factories on a charge of having neglected to fence the shaft of a pipe mill in the fire clay works at Glenboig, whereby a young woman named Jane Davison, was caught by the dress by a revolving shaft and so seriously injured that she shortly thereafter died. Mr Hurll pleaded guilty and the Sheriff sentenced him to pay £70 with £1 3s of expenses and failing payment, 2 months imprisonment. The Sheriff in giving his decision requested the Government inspector to communicate with the Secretary of State as to the payment of the fine to the parents of the deceased as provided for in the Act.

August 1881 – Invoice – Invoice – Glenboig Fire Clay Company, Glenboig Fire Brick Works near Coatbridge. Office, 68 Bath Street, Glasgow. (The office is also recorded on this invoice as being 188 Buchannan Street, Glasgow but this has been scored through). Fire bricks, sewerage pipes, chimney cans, silver sand.

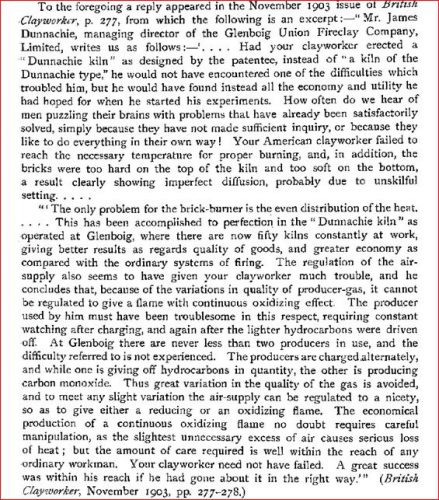

13/10/1881 – Glasgow Herald – Important improvements in burning fire bricks. A new application of heat regeneration. During the last twenty years or so, and more especially since the Bessemer and Siemens processes of making steel came to be established as great manufacturing industries at home and abroad, the district of Glenboig, near Coatbridge, has acquired a great reputation for the character of the bricks and other goods from the millstone grit fire-clay which has been so beautifully deposited in that particular portion of the Lanarkshire coalfield. For furnace construction, there is nothing to surpass a genuine Glenboig brick in respect of its fire-resisting power unless it is that peculiar product of South Wales manufacture known as the Dinas fire-brick, which, however, is almost exclusively composed of silica and has but a limited range, of practical application. When some important improvements in burning fire-bricks are completed it may confidently be expected that Glenboig manufactures will rise still higher in reputation. Occasionally in recent years some of the manufacturers of fire-bricks of this country have considered it desirable to adopt the heat regenerative system to the burning of such goods, but in no attempt that has been made, so far as we are aware, has any marked economical result been attained until within the last two or three weeks. The special case to which we are about to refer is that of Mr James Dunnachie, of the Glenboig Star Fire-Brick Works, where there are manufactured goods of such remarkably refractory power as to be in, great demand for furnace construction. Having a raw material of such splendid quality as a fire-resisting medium, it was but natural that the gentleman whom we have named should exert every endeavour to turn it to the best possible account, both in the preparing and moulding stages of the manufacture and in the economical and perfect firing of the bricks after being prepared. Having lately inspected the new firing arrangements at the Star Fire-Brick Works, we give a brief sketch of the modus operandi pursued by Mr Duunachie and we would just remark in passing that the arrangements in question, which have long been worked out, were first brought into practical use in connection with the adoption of the Wilson, producer to supply the requisite gaseous fuel. It is not necessary that we should here describe that useful and valuable invention, but it is proper to state that this is the first occasion for it to be employed in the successful burning of fire-bricks. As at present developed, the arrangement adopted is a kiln consisting of two parallel stacks of brick work, about 24 feet apart, and each containing five separate chambers, in each, of which from 13,000 to 14,000 bricks can be fired at one “heat.” In order that the kiln may be capable of continuous regenerative firing the two sets of chambers are connected with each other at the two ends by means of under-ground flues, and in this way the ten chambers may be regarded as one continuous series – that number being required for completely carrying out the ideas of the inventor, The space between the two parallel stacks of brickwork is covered in by means of an iron roof, so that the operations of charging the green bricks and discharging the finished goods may be pursued in all kinds of weather. ‘There are, however, doors at both ends of the chambers. At the west end of the space just referred to there are erected two of Wilson’s gas producers of large proportions, for which the gaseous fuel is led to the underground flues for working the separate chambers when charged with bricks to be fired. One great advantage of this system of heat-regeneration in burning fire-brick is that there is always a regenerator chamber in readiness for heating the air requisite for the combustion of the gaseous fuel. Of course, in commencing the process at the Star Fire-brick Works it was necessary to fire the first chamber in the usual way by means of specially erected coal furnaces, but as soon as it was fired off, it was ready to become part of the future plan as the first regenerator chamber. At the time of our visit, the system was in successful operation with one set of five chambers, and the stack of brickwork containing the other five was in rapid progress. ‘The experience with the gas-fired kilns up to the present is that the firing operation can be thoroughly performed in from 18 to 24 hours, whereas in the best type of kilns used at the same works, employing coal as the fuel, the burniug usually occupies from four to six 12-hour shifts. It is not considered a too sanguine expectation to suppose that, if desired, the time required for burning off a kiln chamber under the new order of things may eventually be reduced even to 12 hours. There is no necessity, at this early stage of Mr Dunnachie’s operations, for giving any detailed account of the structure of his new kiln, and we, therefore, limit our remarks to a brief notice of the mode of employing the gas and air – the fuel and the supporter of combustion. Assuming, then, that No. 1 chamber has been fired off, and that the effluent gases produced in the combustive process have passed through chamber No. 2, which is the next in the series, the contents of the latter are now in all probability at a bright red heat; the gas from the producers – at a temperature of from 600 degs to 800 degs Fahrenheit – is turned on direct to No. 2. and so likewise is the highly-heated air that is streaming through No. 1 – the regenerator chamber. These two currents are allowed to mix in the fires or burners beneath the floor of the chamber, and a magnificent glowing effect is soon evident. The underground flues are provided with valves that can be brought into action at a moment’s notice for turning on or turning off the gaseous current and regulating it according to the condition of the mass of bricks being operated on at the time. These valves are worked in the covered space formerly referred to and at what may be termed the working front of the kiln. The quantity of air that passes from the regenerator chamber is regulated by means of dampers, which are also under the most complete control. At the end of from 18 to 24 hours, the firing is completed, and the particular chamber that has just been burned off becomes, in its turn, the regenerator for the next in the series, which by this time has doubtless already attained to a full red heat through the action of the heat of the effluent gases, but which heat is economised in the manner indicated. And in this way, the new system of using gaseous fuel in the fire-brick manufacture may be fitly spoken of as one of continuous heat regeneration. The economy already attained as regards fuel is very significant, the saving of which is upwards of 50 per cent, and there is every reason to expect that it will yet reach 75 per cent when the other five-chambers are brought into use. Besides the economy in fuel just stated, and the speed in burning, the special features of the new system of firing that have been aimed at and attained are the use of gaseous fuel, combined with the perfect diffusion of the heating current. Owing to the manner in which the gas and air flues are arranged in each chamber the most absolute perfection is attained in the admixture of the gas and hot air for the burning process before they are admitted into the kiln chamber proper. It is also worthy of mention that, if the front of the kiln should become too hot, cold air can be admitted at pleasure, and that it is possible to take off the effluent gases from any one chamber either at the top or bottom. Furthermore, the heat current may be conveyed directly to the next chamber in the series, so that there is practically no waste of heat at any stage of the process. From all the various circumstances which we have mentioned, we may (using the remark of a competing manufacturer of fire-bricks) characterise Mr Dunnachie’s new system of burning bricks as being a revolution in the manufacture. So for as can be seen at present, there is abundant reason to believe that the same system of using gaseous fuel in continuous regenerative firing may be adopted with an equally marked economy in the manufacture of pottery ware and in other more or less similar industrial processes.

04/11/1881 – Dundee Courier – A letter was read from the Glenboig Fire Clay Company stating that they were working up to stoop the fireclay below the school at Glenboig and the matter was remitted to the clerk to examine the plans and report at the next meeting.

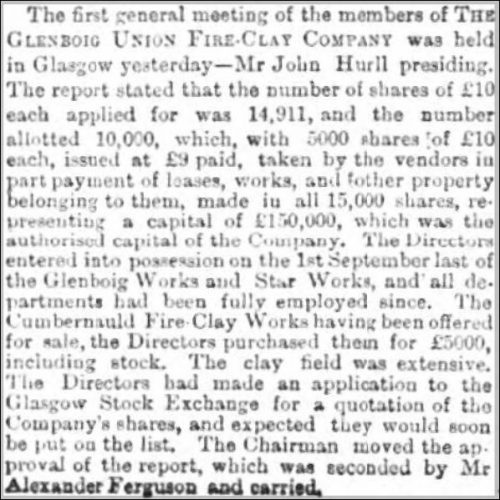

1882 – The Starworks and the Old Glenboig Works companies decided to amalgamate as the Glenboig Union Fireclay Company Ltd with Dunnachie as Managing Director.

1882 – The Cumbernauld Fire-clay Co (founded 1874) or Cumbernauld Fireclay Works and Mine, had works beside the Caledonian Railway with fire-clay from Abronhill. In 1882 the Works are sold for £4000 to the newly formed Glenboig Union Fire-Clay Co, under James Dunnachie. The company was registered on 26 August, to acquire the businesses known as the Glenboig Fire Clay Works and the Glenboig Star Fire Clay Works, carried on by James Dunnachie and the Glenboig Fire Clay Co respectively at Glenboig, near Coatbridge, Lanarkshire.

Below – 23/12/1882 – First General meeting of the members of the Glenboig Union Fireclay Company – John Hurll presiding.

06/06/1882 – Invoice – James Dunnachie, Star Fire Brick Works, Glenboig near Coatbridge. Office, Victoria Buildings, 2 West Regent Street, Glasgow.

Dunnachie’s invention of a gas kiln for firing bricks was to earn him even greater praise and money. The gas kilns first proved themselves at the Company’s works at Glenboig, Cumbernauld and Gartcosh, as they allowed greatly increased temperatures and considerable savings in fuel costs.

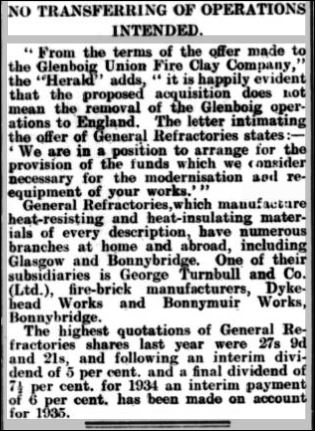

Palacerigg Mine 1884-1958 called the “Glen Cryan Mine” was first run by Glenboig Union Fireclay Co. Amalgamated with General Refractories of Sheffield (but continued to trade in Scotland under the Glenboig name).

1883 – 1897 – Invoices – Numerous. All headed The Glenboig Union Fireclay Co Limited, Victoria Buildings, 4 West Regent Street, Glasgow.

Below – 03/02/1883 – Glenboig Evening Post –

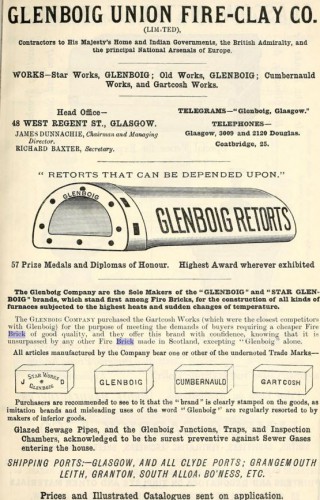

05/02/1883 – Glasgow Herald – James Dunnachie and others V John Young & Sons. The complainers here are the proprietors of the Star Fire-Brick Works, Glenboig, near Coatbridge, and the Glenboig Fire-Clay Company, Glenboig, and they sought to interdict the respondents, who are sewage-pipes and fire-clay goods manufacturers, Heathfield and Cardowan, Lanarkshire, from selling, shipping, or exporting any fire-clay goods stamped with the word Glenboig other than fire-clay goods manufactured by the complainers. They state that the clay obtained in the Glenboig seam, which is co-extensive with the farm of Glenboig, is of superior quality, that it is especially valuable in the market, that it belongs to and is marked by them; and that the respondents have been making and selling goods under the name of Glenboig with the view of deceiving purchasers. Last year the Lord Ordinary on the bills granted interim interdict and ordered answers. In these the respondents say that they own and work the clay of the Glenboig seam; that the clay is identical in quality through the whole extent of the seam, extending beyond Glenboig Farm; that the goods made a from it are known as Glenboig goods by whom-so- ever made, and that the term is not confined to goods made by the complainers. In addition, they maintain that the trade and the public have long known that they made goods from the Glenboig seam and sold such goods as Glenboig and further, that it was a recognised custom that all goods manufactured from a particular seam should be so described, no matter who made them. Evidence was led at considerable length a fortnight ago, and today decision was given in favour of the respondents. The Lord Ordinary said that there were two things which the interdict was intended to strike at – first, the imitation of the trademark of both or either of the complainers; and, second, the use of the name “Glenboig” at all, not merely as a trademark in the proper sense, that was, as a distinctive mark impressed upon the respondents’ goods, or affixed as a distinctive word in catalogues, advertisements, or in any other way to designate goods manufactured and sold by them, and that irrespective altogether of the meaning that they may take to inform their customers or the public that they are not goods manufactured by either of the complainers. The second of these claims was pressed by the Solicitor-General, who stated that certain circulars and advertisements which the respondents had been in the habit of issuing for many years without complaint could not have been effectively challenged although they fell within the terms of the interdict now asked. His Lordship did not now understand it to be maintained that the complainers had acquired such an absolute and exclusive right in the use of the word Glenboig that they were entitled to prevent another manufacturer employing it as a distinctive of fire-clay goods which were not themselves marked with it, even though he did so in a way neither calculated nor intended to deceive. Nor was it intelligible that such an exclusive right to the use of a distinctive name should be vested at the same time in two independent and competing manufacturers. The question requiring consideration, therefore, appeared to his Lordship to be whether the complainers were entitled to interdicts in the terms asked against the use of the word “Glenboig” by the respondents a trademark, or against his use of that word in combination with another word or words because it was perfectly clear that the use of the word “Glenboig” by itself would be a direct invasion of the Glenboig Company’s right. The two complainers are tenants of portions of a bed of clay lying under the lands of Glenboig, and each of them has works situated upon the lands. Their averment and it was entirely borne out by the evidence, was that the clay on the Glenboig Farm possessed many exceptional qualities, and was described as possessing to a larger extent than other fire-clays the power of resisting heat at high temperatures, and in particular that the goods made from it are free from the risk of cracking after being subjected to an extreme heat. This was a most valuable quality in fire-clay goods. And then the complainers went on to say that the goods manufactured by them had acquired a favourable reputation in districts where they were used, as Glenboig goods. Each of the complainers is the registered proprietor of a trademark which they impress upon the goods manufactured by them. The Glenboigs Company’s mark consisted of the word ‘Glenboig’ alone, while Messrs Dunnachie’s mark is a device consisting of the words ‘Star Works, Glenboig’ with a star and the initials ‘J D’ between these two letters. The complainers said, and they quite clearly proved, that these two words, ‘Glenboig’ and ‘Glenboig’ Star’ had established a reputation for excellence, and commanded a high price both, in the home and foreign markets. There could be no doubt that the complainers’ goods were in great demand and had a fair reputation both in this country and on the continent, and that reputation, which was proved to be well merited, was of great commercial value. There could be as little doubt that this high reputation was attributable not to any peculiarity or special excellence in the manufacture, but to the distinct qualities of the Glenboig clay. It was not disputed that the complainers are excellent manufacturers and that they would not have acquired a reputation for their fire-clay goods had they not been well and carefully made, but at the same time there was nothing exceptional in their process, and if the same material had been wrought by another competent manufacturer his goods must have obtained the same currency and demand as those of the complainers. Without going into details, his Lordship was of opinion that the respondents, who are the lessees of a fire-clay field in the immediate neighbourhood of the complainers, began about eight years ago to work a seam identically good in quality to the seams worked by the complainer. It was, in his opinion, perfectly immaterial to consider whether there was uninterrupted continuity of a strata between the mineral field worked by complainers and the mineral field worked by the respondents. For all practical purposes, they were working the same seam, and his Lordship thought it had been proved that before the respondents reached that seam it was known among engineers and fire-clay manufacturers to extend beyond the limits of the area leased by the complainers and that both within and beyond that area it was known by the name of Glenboig clay, and by no other name. Now it appeared to his Lordship that as soon as the respondents had reached Glenboig clay and had begun to work it they were in entitled to take advantage, not of the complainer’s reputation as manufacturers, but of the reputation of the valuable raw material which they had ra acquired and accordingly it was hardly disputed in the argument that they were justified in issuing circulars in 1874 stating that they were engaged sinking a pit to the fire-clay known as the Glenboig seam. From that time downwards they had constantly advertised in various forms that they were manufacturing bricks from the clay known as Glenboig. That had been done without challenge from any of the complainers. Assuming these proceedings to be within the respondent’s rights, it was of course clear that they were not entitled to imitate the trademark of the complainers or in any other way to represent that the goods they sold were goods manufactured by the complainers. The complaint was that the respondents proposed to brand their bricks with the words ‘Young’s Glenboig’ and this was said to be a mere colourable imitation of the trademarks of the complainers. But neither of the complainers, in His Lordship’s opinion, was in a position to maintain that the use of the word “Glenboig,’ although accompanied by a distinct variation, was in itself an infringement of his trademark, because each of them as against the other had a right to the use of that word. They were competing against each other in the home and foreign markets, which conceded a right which in this action they both denied to the respondents. The only question, therefore, appeared to be whether the variation which had been adopted by the respondents was sufficiently distinctive. In his Lordship’s opinion the brand ‘Young’s Glenboig’ was just as distinguishable from Mr Hurll’s ‘Glenboig’ and Mr Dunnachies ‘Star Glenboig’ as either of these was from the other. There had been a great deal of evidence on this point, but it had been entirely in accordance with the conclusion that His Lordship had arrived at, that the brand ‘Young’s Glenboig’ could deceive nobody. But it had been said that in Russia and Germany it would be different. If it were so it might be a question how far that which was otherwise an ordinary bona fide trademark, used by a trader in this country, and unimpeachable here, could be prohibited and interdicted, merely because it was liable to lead to misapprehension in particular markets. There was no authority, so far as he knew, for that proposition. The marks being, names or words in the English language, they would be quite distinguishable wherever the words could be read and understood. On the whole, his Lordship was of opinion that the interim interdict formerly granted must be recalled, and the note of suspension refused, with expenses to the respondents …

23/05/1883 – Glasgow Herald – James Dunnachie and others V John Young & Sons – The complainers and reclaimers here are the proprietors of the Star Fire Brick Works, Glenboig, near Coatbridge and the Glenboig Fire Clay Company, Glenboig, and they sought to interdict the respondents, who are sewage pipes and fire-clay goods manufacturers, Heathfield and Cardowan, Lanarkshire from selling, shipping, or exporting any fire-clay goods stamped with the word Glenboig other than fire-clay goods manufactured by the complainers. There was a further conclusion in the prayer of the petition against the respondents advertising, for sale any goods as Glenboig goods other than those manufactured by the complainers, and also to prevent them, using the words objected to on invoices, memorandums, &c. The Lord Ordinary Kinnear after hearing evidence in the case issued an interlocutor finding in favour of the respondents, with expenses. A reclaiming note was presented against this decision, and upon it, counsel were heard towards the end of the last session, and avizandum was then made. Today the Court decided the case.

The Lord Justice Clerk, who gave the leading opinion, said that two questions were raised in this case – first, whether the respondents had assumed and applied to articles manufactured by themselves the trade name in use to be applied by the complainers to articles manufactured by them, and that for the purpose of inducing purchasers to believe that such articles were manufactured by the complainers; and secondly and separately, whether the respondents had used arid applied to their own ware the registered trademark of the complainers. The relative position of the parties to this dispute, His Lordship said, might be very shortly described. Both were manufacturers of goods from fire-clay, their works being situated about two miles from each other, and they used in their manufacture the clay found in the lands on which these works were placed. The name of the lands on which the complainer’s works stood was Glenboig and that of those occupied by the respondents Heathfield. The same seam and quality of clay were found in each. It had been the invariable practice in this trade to name the ware manufactured at the different works by that of the lands which they occupied, and thus the manufacture of the complainants had been universally known in the trade as Glenboig, and that of the respondents as Heathfield and they passed under these denominations in the market, and the ware, had been stamped with these respective names. It appeared, however, that the Glenboig fire-clay had attained a reputation in the market which Heathfield had never reached, and hence this controversy. The superiority of Glenboig was attributed by Heathfield to the fact that the former used in the manufacture a seam of clay of fine quality, which, although existing on the Heathfield lands also, the respondents had not been fortunate enough or skilful enough to arrive at. At last, in 1874, their workings struck this seam; and not allowing the excellence of their ware to make it known to the trade, they had pursued a system of advertisement in order to publish the fact that they were working the same seam of clay as that found at Glenboig, until at last, in 1882 they began to stamp the Heathfield ware with the words ‘Young’s Glenboig’. The object of these proceedings was not disguised. The Heathfield ware had no connection whatever with the neighbouring works, any more than it had with the other fire-clay fields in the vicinity, where precisely the same seams of clay occur; and it would have been quite reasonable to have called these fire bricks by the name of Garnkirk, Gartcosh, or Cumbernauld, as to stamp them with the name of Glenboig. The object of the proceeding was to attract to Heathfield goods part of the popularity of Glenboig. But it was said that in stamping their ware with the word ‘Glenoboig’ the respondents did not mean the trade or the public to understand that these goods were made at Glenboig, but only that they were made out of a seam of clay which they alleged to be known as the Glenboig seam. If it were material to the question before the Court his Lordship thought the evidence brought to establish that the word ‘Glenboig’ was known as a generic name applicable to a particular seam of clay wherever found, was both untrustworthy and inconclusive. The perusal of it had satisfied His Lordship that until the respondents commenced their advertisements in 1874 there was nothing like a general or even a partial use of the name in this sense even among scientific men. But it was quite sufficient for the present purpose that the witnesses were all agreed that until 1882 the invariable practice in the trade was to name the fire-bricks after the name of the lands on which they were manufactured and that none were even known to be named after a particular seam of fireclay. It followed from this universal custom that the name of Glenboig meant in the trade when applied to fire-bricks, those manufactured at the Glenboig Works, and was not understood or intended to mean anything else. His Lordship came to the conclusion, and with no hesitation that in stamping their goods with the words ‘Young’s Glenboig’ the respondents intended their customers to believe that they were manufactured at Glenboig and that because of the high reputation which that manufacture had attained in the trade. They could not mean their customers to believe that the word ‘Glenboig’ merely described the seam, because they knew that this was never done in the trade. On this part of the case, His Lordship said, he should desire no further evidence than that afforded by the immediate facts out of which this dispute had arisen. In 1882 the complainers received an order from a Glasgow firm for a large quantity of fire-brick. The complainers were too busy to undertake it, and they recommended the respondents to their customers. In the execution of this order, the respondents for the first time used the stamp ‘Youngs Glenboig’. The complainers immediately remonstrated, and Mr Young at once expressed his deep regret and said it had been done without his knowledge and that it was very wrong and should not happen again, and entreated the complainers to intercede with the Glasgow firm to accept the goods without the word ‘Glenboig’ stamped on them. But the Glasgow firm were obdurate. They wanted the stamp of Glenboig because their customers would accept no other, proving clearly that the trade attached no consequence whatever to the seam of clay from which they were manufactured and cared only for the stamp of the Glenboig manufactury. If this were so the addition of the word ” Youngs” was merely colourable. His Lordship was therefore entirely with the complainers on the first point and the second became immaterial. He was, however, of the opinion that the respondents had infringed or adopted the registered trademark of the complainers. But it had been contended that the respondents had not adopted the trademark, because ‘ “Young’s Glenboig'” was not the trademark. This contention appeared to His Lordship to be quite inadmissible. The respondents were not entitled to use the trademark and had no reasonable excuse for doing so and the addition of their own name would not justify them in adopting the trademark of their neighbour. It was said that Mr Dunnachie, who was also a manufacturer on the lands of Glenboig, had used without objection from the other respondents the trade name of ‘Star Glenboig’ and that, therefore, anyone who chose might adopt the trademark of the company if any other word were put before it. His Lordship could not see anything in this view, or any analogy between the cases. The ‘Star Glenboig’ ware was rightly and honestly so-called, unlike that of the respondents. It was Glenboig ware. The name expressed nothing but the truth, Whether the assumption of that designation would or would not have been an infringement of the other company’s trademark the court needed not to consider because it was not challenged. It did not follow that the trademark would have been acquired at all but for the acquiescence of the company in the modification thus introduced. His Lordship was, therefore, prepared to grant interdict prayed for in the first part of the prayer. In regard to the advertisements, although they were ambiguous and perhaps disingenuous, he was not prepared to say that they all constituted a violation of the complainer’s right. The respondents were entitled to say that their seam of clay was the same as that found in Glenboig, for that appeared to be true, but they were bound to make their meaning quite distinct and to use no word which could lead to the inference that the goods referred to were made at Glenboig. But the prayer of the petition was much too wide and he thought the complainers would be well advised if they confined their demands to interdict against stamping the goods and depart from the rest of the prayer. The other judges concurred in this opinion.

Mr Trayner for the complainers said that they accepted the suggestion of the bench and they did this all the more readily that they honestly believed that Messrs Young would be as glad to yield real obedience to the court as the complainers were to accept the suggestion.

A short discussion then took place on the question of expenses and the court on the grounds that the complainers had been substantially successful, gave them expenses …

17/09/1883 – The Scotsman – The following is the list of awards to Scottish exhibitors at the International, Colonial and Export Exhibition, Amsterdam 1883. Gold medal – Glenboig Union Fireclay Company Limited, Glasgow.

11/09/1883 – Ayrshire Post – Patents for inventions. List of specifications published during the week ending 1st September 1883, prepared by Geo. M. Cruikshank, patent agent, 133 Buchanan Street, Glasgow … Dunnachie silica bricks …

25/10/1883 – Glasgow Herald – The annual general meeting of the Glenboig Union Fireclay Company Limited was held yesterday in the company offices, West Regent Street. Mr John Hurll presided and there was a large attendance of shareholders … their customers were spread over Europe and America and they had shipped large quantities of goods during the past year, more indeed than had been sent for many years. The French, German and Russian trade had been fair. They had had some trouble in regard to an infringement of their trademarks but the company had been successful and they were not likely to be interfered with in future … dividend 9% …

Below – 1884 – Property Index 1884

14/06/1884 – Lanarkshire Upper Ward Examiner – Glenboig was the scene of considerable rejoicing on Tuesday last. Banners were flying all day in various parts of the works, guns were fired at intervals during the afternoon and evening, and, as soon as darkness began to set in, great fires were raised, leading the passengers by the trains to ask the question, ” What’s a’ the steer ?’ It was the marriage of Dr John Murray of Chryston to Miss Mary Jane Gibbes. The celebration took place at Glenboig in the house of Peter Hurll, Esq, brother-in-law to the bride, the officiating clergyman being the Rev. John Moodie of Kippin, formerly of Chryston. On the afternoon of Saturday last, at a meeting held in the schoolroom, Mr Thomas Dunnachie, in name of the employees of the Glenboig Union Company (Ltd.), presented the doctor with a valuable marble timepiece, and Miss Gibbes with a pair of bronze statues and a set of beautiful fruit knives, as a token of esteem, on the occasion of their marriage

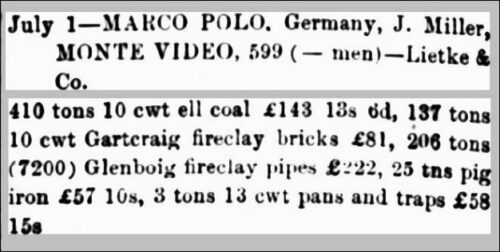

Below – 17/01/1885 – Clyde Bill of Entry and Shipping List – Glenboig Union Fire Clay Company Limited.

26/01/1885 – The Scotsman – Glenboig Union Fire Clay Company Limited V John Young & Son. Another court case brought about by the Heathfield works using the Glenboig trademark. Heathfield appears not to have adhered to the Court’s decision in 1883 that they were wrong to use the Glenboig name.

14/03/1885 – Edinburgh Evening News – In the Court of Session today, it was intimated to LordJFraser that the action at the instance of the Glenboig Union Fireclay Company, West Regent Street, Glasgow, against John Young & Sons, Bath Street, Glasgow, in which interdict was asked of defenders advertising themselves as manufacturers of “Glenboig,” “Glenboig Fire,” ” Glenboig (Young’s),” “Young’s (Glenboig),” fire-clay goods, and, in addition, damages to the amount of £5000 were asked, had been settled. Defenders said that for 25 years they carried on business at Glenboig, and prior to 1873 Mr John Young, of their firm, was in partnership with the gentlemen who now direct the pursuers’ company. The term “Glenboig” was maintained, was not confined to pursuers’ goods, but was distinctive of goods manufactured from Glenboig clay. Counsel intimated that interdict was to be given, £5 paid damages, and it was proposed that neither party be found entitled to expenses. Exception was taken on behalf of the pursuers to the length of the minute agreement and his lordship today merely allowed it to be received and seen, reserving discussion upon that point.

26/08/1885 – Dundee Courier – The Antwerp Exhibition – Scotch awards – Gold medal, Glenboig Union Fireclay Co Ltd. They also received a bronze.

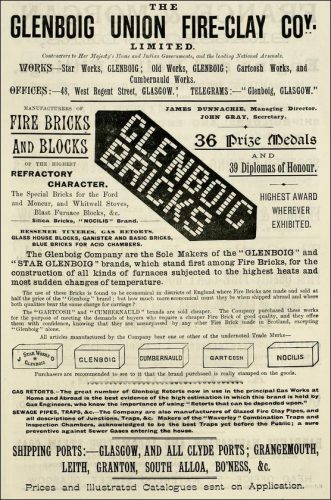

Below – 1886 – Glenboig Union Fireclay Co Advert – (Note SBH – “contractors to her majesty’s home and Indian Governments ” – At this time or thereafter I theorise that Glenboig started to add a ‘crown’ design to their bricks).

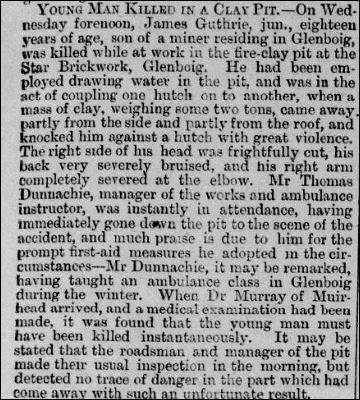

Below – 01/05/1886 – Rutherglen Reformer – James Guthrie was killed while working in the fire clay pit at the Star Brickworks, Glenboig. James Dunnachie assists with medical treatment.

24/07/1886 – London Daily News – Prospectus for Thomas Carr and Son, Fireclay manufacturers … The new gas process is already in operation in some of the largest Fireclay and Brick and Tile Works in the Kingdom, amongst which are the following: Glenboig Star and Cumbernauld Fire Clay Works of the Glenboig Union Fireclay Company and the Garnkirk Fireclay Works …

04/10/1886 – Annual General Meeting of the Glenboig Union Fireclay Co records John Gilchrist Stein as a shareholder.

Below – 05/02/1887 – Clyde Bill of Entry and Shipping List – Glenboig Union Fire-Clay Co Ltd.

24/12/1887 – South Australian Register, Adelaide. J Stilling & Co, Cavendish Chambers, Grenfell Street, Adelaide are sole agents in South Australia for Glenboig Fireclay Company’s firebricks

1888 – In 1888 the architect Clarence Backhouse clad a whole of the front facade in Glenboig bricks at the NSW Electric Light and Power Supply building in Kent Street, Sydney, Australia. These were not necessarily the ‘Starworks’ bricks from Glenboig referred to above, but possibly the products of the Glenboig Union Fire Clay Co, which were currently on show at the Centennial International Exhibition.

24/04/1888 – Hamilton Advertiser – Glasgow Exhibition. The Glenboig Union Fire Company (Limited) show a most complete exhibit of fire clay articles used for metal smelting at home and abroad. It includes the fire bricks blocks required in the manufacture of steel, iron, copper, brass, lead, glass and the special bricks for the Siemens, Gormon, Ponsard, Klonne, Coppee, Cowper, Whitwell, Ford & Moncur and Bauer furnaces and ovens, gas retorts and all kinds of settings, glazed sanitary pipes, traps, syphons &c, ganister & silica furnace bricks, Glenboig ironstone paving tiles for railway stations and other public places, fireclay ground and unground, silver sand &c. The Glenboig Company have received 22 prize medals at the various International Exhibitions and have never failed to secure the highest award given for their class of goods.

20/06/1888 – Colonies and India – The Barcelona Exhibition – The Glenboig Union Fire Company (Limited), Glasgow. This company is represented by a large collection of their Glenboig bricks and fireclay goods. The superiority of the Glenboig fireclay over that from other mines has long been established as it is remarkably free from any bases such as oxide of iron, lime &c, that have a tendency to make the clay softer with heat. The potash contained in it is also much lower than usually found. These qualities render the Glenboig bricks&c peculiarly serviceable for an almost innumerable variety of purposes and especially so for stoves, blast furnaces, kilns &c. The company have built gas retorts for a number of gas companies in the United Kingdom and have had nothing but pleasing and satisfactory reports in connection with any of them. The clay also lends itself to many uses of a decorative nature and many pleasing designs have been fashioned for such purposes as flower stands, garden tables, seats &c while for chimney pots, grate backs or flooring tiles it is used in endless varieties.

Below – 09/09/1888 – Glasgow Herald – Formation of a co-operative society in Glenboig. Mr Hurll addressed the meeting.

12/12/1888 – Glasgow Herald – Melbourne exhibition – … The Glenboig Star Fire Brick Works near Coatbridge, Scotland has an extensive variety of fine brick articles, samples merely of different things from a fire brick and numberless patterns in varied forms up to pipes and drains of many sorts and sizes …

Below – 1889 – Glenboig Union Fireclay Co Advert.

02/03/1889 – Glasgow Herald – A few labourers wanted. Wages 16s per week. Apply Star Works, Glenboig.

12/10/1889 – Lanarkshire Upper Ward Examiner – A man named Bernard McGinty, who was described as a pest from Glenboig, was on Saturday sentenced to sixty days imprisonment by Sheriff Mair at Airdrie, for breach of the peace. The accused, who has been frequently convicted of the same offence, had gone to the house of Mr Jas. Dunnachie, manager of Glenboig Union Fireclay Company, and caused great annoyance.

16/10/1889 – Glasgow Evening Citizen – The annual meeting of the above company was held today at 4 West Regent Street. Mr John Wilson, M.P., who presided, in moving the adoption of the report, mentioned that the company had received two gold medals and a silver medal at the Paris Exhibition; a medal from the Barcelona Exhibition – the first prize for fire-clay refractory brick. They had written off since the beginning of the company in 1883 as much as the cost of all the additional plant they had put down in the old works, as well as the cost of putting the whole work into proper shape. They had also written off, so far as depreciation was concerned, the plant they had erected for the steelwork bricks and had practically written off the Cumbernauld works, which had cost them £4000. They now stood in the same position as they did in 1883 with a capital of £110,000. That, he thought, was very creditable, while they had also this year added to the dividend of the company 50% l from what it was in the previous year. He thought that the year upon which they had entered would prove very much more satisfactory than even the last. (Applause.) The prospects of trade were such that they could hardly keep pace with the demand, although they had added to the production of the old Glenboig works since taking them over nearly a third more. He concluded by moving that report be adopted, and that a dividend at the rate of 6 per cent, per annum, free of income tax, be declared. Mr Craig having seconded, the report was adopted, and the dividend accordingly declared. On the motion of Mr Young, seconded by Mr Hamilton, Mr James Craig and Mr William Kennedy were re-elected as directors. A vote thanks to the Chairman terminated the meeting.

1890 – The Glenboig Union Fireclay Company took over the operation of Gartcosh Works (perhaps this means the fire-brick works?)

12/04/1890 – Lanarkshire Upper Ward Examiner – Article about a social meeting of Glenboig and district railway employees … the other day a gentleman asked Mr Dunnachie in my hearing, how many bricks do you produce in a day? Mr Dunnachie replied one hundred thousand …

17/09/1890 – Dundee Courier – Dividends – Glenboig Union Fireclay Company Limited at a rate of 10%.

10/10/1890 – Glasgow Herald – Awards at Edinburgh exhibition – Diploma of honour – Glenboig Union Fireclay Company Limited, Glenboig near Coatbridge and Cumbernauld – Fire bricks, silica brick, sewage pipes and fittings.

1890 – 91 – John A Robertson, Shipping Clerk, Glenboig Union Fire Clay Co, 4 West Regent Street, Glasgow. House 93 North Fredrick Street.

New Zealand Crown Mines Company registers in Scotland and James Dunnachie Glenboig is one of the first directors.

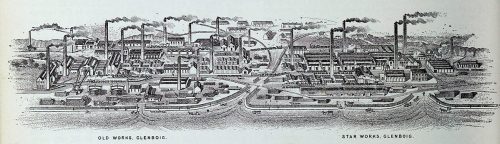

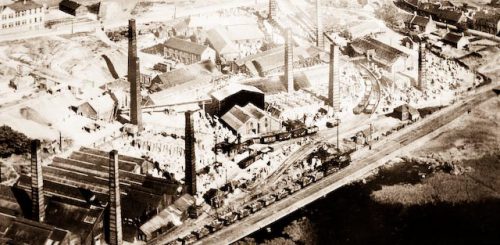

Below – 1891 – Old Works and Star Works, Glenboig.

20/06/1891 – Airdrie and Coatbridge Advertiser – The annual trip of the Glenboig Union Fire Clay Company’s workmen, employed at Glenboig, Cumbermauld and Gartcosh, came off last Saturday. The place visited was Edinburgh. “Edina Scotia’s darling seat.” The excursionists, numbering about 300, left Glenboig about 8 o’clock. Mr Brown, the courteous and obliging stationmaster, doing his utmost to get everybody comfortably seated. Arriving at Edinburgh about 9.30, all took their several ways. A good number visited the Forth Bridge and beheld in amazement that stupendous structure of engineering skill. Some spent the day in Portobello, but most of the excursionists remained in Edinburgh and visited Holyrood, the Castle, the Industrial Museum and all the interesting sights of the city. Home was reached safely about 9 o’clock, and everybody expressing themselves as being satisfied with their visit to “Auld Reekie.” The trip was accompanied by the Glenboig Brass Band.

22/10/1891 – Glasgow Herald – The annual meeting of the Glenboig Union Fireclay Company was held yesterday in the offices, West Regent Street. Mr John Wilson, M.P., in the chair. The Chairman in moving the adoption of the report (which we have already published), said that they had purchased an extensive new work, at a moderate price, and although a large sum of money had been spent in putting it into working order, the work would now be carried on to the satisfaction of those who had been engaged in it and that it would ultimately be profitable to the company. He had no doubt whatever that in the future the alterations that they were making upon the Gartcosh Works, although pretty extensive, would be beneficial to the company. In the meantime, the works were in operation, and it was satisfactory to know that they had got an inexhaustible bed of clay. At Glenboig there had been a considerable expenditure in opening up a new mine, which was being worked upon a system that would tell very materially in handling fire-clay and bringing it into the mill. The haulage had been laid down in such a way that it would be conducted with very little expense. There had also been an extension of the gas system of firing put into operation which had been satisfactory. He was glad to state that in the department for the manufacture of the silica bricks they had been singularly fortunate. There was such a large demand for them that they had to extend the process, He moved the adoption of the report, and that a dividend of 2 1/2 per cent., less income tax be paid on 11th November. Mr Hamilton seconded and the motion was adopted. The retiring director was reappointed, and Mr Wylie Guild was reappointed auditor.

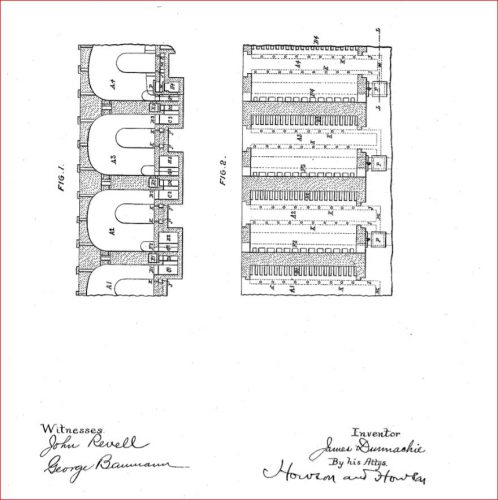

27/10/1891 – James Dunnachie – Brick kiln patent. James Dunnachie, of Glenboig, Scotland. Brick Kiln – Specification forming part of Letters Patent No. 462,036, dated October 27, 1891. (Note – SBH – The reproduction of this article on the internet is full of errors, some of which I could not decipher so some of the narrative below may not make sense).

Application filed November 4; 1890. Serial- .No. 370,308. (No model) T0 all whom it may concern:

Be it known that I, James Dunnachie, a subject of the Queen of Great Britain and Ireland, and a resident of Glenboig, in the county of Lanark, Scotland, have invented certain new and useful Improvements in Kilns for Firing Fire-Bricks, Earthenware, and the like, of which the following is a specification.

My said invention relates to kilns of the kind described in my patent specification, No. 268,771, dated December 5, 1882; and my present object is to improve the operation of such kilns by supplementing the supply of heat at a particular stage of the actions, so as to rapidly drive off moisture from the bricks or other articles prior to the application of the strongest heat.

In the arrangement of kilns to which my present improvements are to be applied a number of chambers or kilns are combined in such a manner that the successive stages of heating, tiring, and cooling are passed through by each in rotation. The firing is effected by the combustion of producer gas, or other suitable gas, in one chamber, and the hot gases after acting in that chamber pass-through ports or flues into the next chamber, and thence through one or more other chambers, so as to utilize their gradually-diminishing heat in heating to different degrees the articles in the several chambers. On the tiring having continued long enough in one chamber the combustible gas is shut off from that chamber and admitted to the next one in order. Air is admitted into the chamber containing the already-tired articles, and while cooling them is itself thereby heated, and this heated air, being led through flues or ports into the next chamber, supplies what is required for the combustion of the gas, at the same time utilizing the heat it has taken up. The flues or passages communicating between the several chambers and those through which the gas is supplied are made with numerous small ports so that the gases are equally distributed over the chambers and uniform action is thereby secured.

By my present invention, I provide for introducing into each chamber during whatever stage of the operations may be thought best a number of comparatively small jets of gas for rapidly driving off moisture from the bricks or other articles in the chamber, these jets issuing through orifices suitably distributed in the floor on the chamber and communicating with one or more special supply flues beneath.

In order that my said invention and the manner of performing the same may be properly understood, I hereunto append a sheet of explanatory drawings, to be hereinafter referred to, and showing the application of my improvements.

Figures 1 and 2 of the drawings are respectively a vertical section and a horizontal section showing a portion of the series of chambers or kilns A A2 A3 A4, composing a set or system of kilns for tiring fire-bricks, earthenware, and the like. If we suppose a charge of bricks to have been just fired in chamber A’, air admitted into that chamber and taking up heat will pass through ports B down into a flue C’, thence through ports into a flue D, and up through ports the passage through Which is controlled by damper slabs into an upper flue E. From the flue E the heated air issues by numerous small ports into the chamber A2 and mixes at once with combustible gas issuing upward through ports F2 from a flue G2, receiving the gas through ports from a supply-flue H2. There are similar ports and flues in connection with each chamber, as indicated by like reference letters distinguished by different numerals, and there are also communications between the chambers at the upper parts of the division walls, as and for the purposes described in my earlier specification, hereinbefore referred to.

According to my present invention, there are formed under the floor of each chamber or kiln two small gas-supply flues J, which are indicated by dotted lines in Fig. 2 and which communicate with the chamber by a number of small jet-orifices K, which I term steaming-holes, as the ignited jets from them cause the moisture from the bricks or other articles in the chamber to be driven off in steam. The lower part of the right-hand end of Fig. l is delineated in section, as at the line L L in Fig. 2, and shows the connection of the small supplementary flues J by a cross-flue M with the larger gas-supply flue H4.

A damper-slab N is provided for closing the opening between the flues M and H4 and is got at through an opening above, to cover which a slab P is provided. When gas is to be admitted to the supplementary flues J of any chamber, it is shut off by a damper or valve Q from the part of the flue H4 communicating with the flue G4 of that chamber.

I claim as my invention- In kilns for firing {ire-brick, earthenware, and the like, a series of firing-chambers having gas-supply flues and ports and dampers therefor, and flues connecting adjacent chambers near the gas-ports to conduct air heated in one chamber into the next, in combination with additional gasp-fines J, and jet-orifices therefrom opening into the bottom of the chambers, said gas-fires. In connecting with the aforesaid gas-supply flues and being provided with dampers, all substantially as described.

In testimony whereof, I have signed my name to this specification in the presence of two subscribing witnesses.

James Dunnachie. Witnesses: David Ferguson, Richard Baxter.

Below – 1891 – 1892 – Glenboig Union Fireclay Co Ltd. James Dunnachie – Manager. John Gray Secretary.

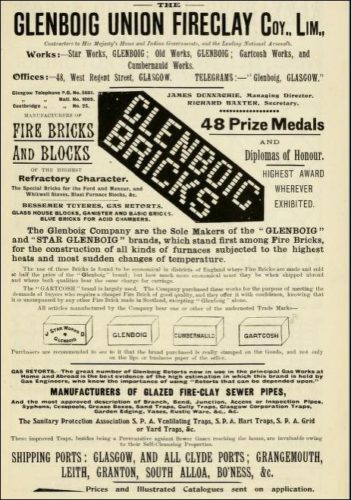

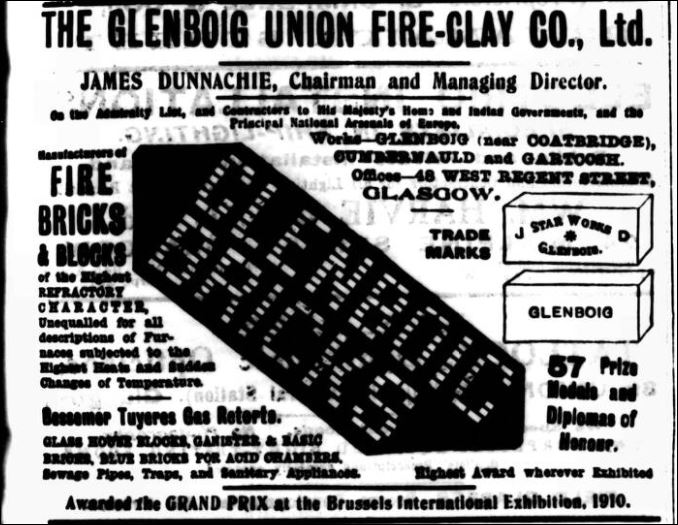

Below – 1891 – 92 – Glenboig Advert James Dunnachie Managing Director. John Trench – Secretary. Nocilis Silica bricks. Also, note “contractors to her majesty’s home and Indian Governments and the leading National Arsenals”

1894 – Glenboig Union Fire Clay Co attend the Antwerp Exhibition. Fire-bricks.

Below – 08/03/1894 – Dundee Courier – Dundee Gas Commission accept tenders. Prices given.

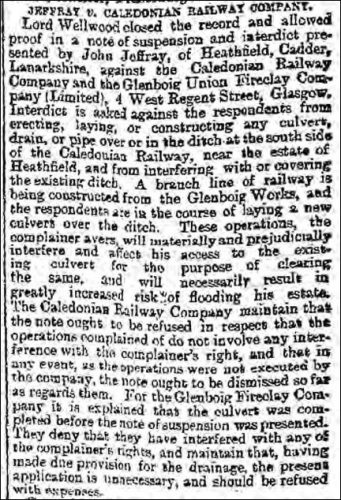

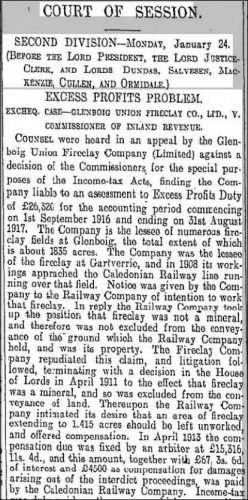

Below – 20/10/1894 – Glasgow Herald – Court case against the Caledonian Railway Company and the Glenboig Union Fireclay Company.

17/04/1895 – Kirkintilloch Herald – An importunate applicant. Robert Chapman, Glenboig, applied for a public house license for premises at Cumbernauld Station. The same application had been repeatedly made and often refused. Mr McFarlane appeared as agent for the applicant, while objections were urged by Mr Wark, on behalf of the Glenboig Union Fireclay Company, and by Mr McBryde on behalf of 69 petitioners resident within a radius of a mile of the station. One of the objections stated was that the applicant had already 3 licenses, 2 in Coatbridge and 1 in Glenboig. A vote was taken, when 20 voted for granting the license and 37 for refusing it. Provost Aitken and Messrs Cameron and Hudson voted with the majority, while Dr Stewart and Messrs Stables and Gardner voted for granting the license

30/10/1895 – Coatbridge Express – Joseph Dollan, (15), Chapelbank, Glenboig met within accident while employed in the Union Fireclay Brickworks on Monday week, two iron plates. weighing 2 1/2 cwts having fallen upon his legs, whereby be sustained a simple fracture of the right shin bone. He was attended to by Dr Marshall, Coatbridge, and removed to the Glasgow Royal Infirmary.

21/11/1895 – Glasgow Herald – The body of Edward Meaghen, about 30 years of age was found in the Upper Dock yesterday. The deceased had arrived in Grangemouth in the beginning of last week from Glenboig to superintend the loading of the vessel Duisburg with his employer’s bricks and had been missing since Friday night. As a cap was found floating in the dock on Saturday it was supposed that the deceased must have fallen into the water. A party with policemen made a search in the dock with grappling irons with the above results. The body was removed to the mortuary.

Below – 1896 – Advert Glenboig Union Fireclay Coy.

23/09/1896 – Dundee Courier – Dividends – Glenboig Fireclay Company at the rate of 7½%.

1897 – Link to a map of Glenboig showing the various brickworks.

19/10/1897 – The Scotsman – Brussels International Exhibition – The Diploma of Honour, an award higher than the gold medal has been given to the Glenboig Fireclay Union Company Limited at the Brussels International Exhibition for their exhibit of fire bricks and furnace blocks and 2 silver medals for sanitary and vitrified goods.

21/10/1897 – Glasgow Herald – The 15th annual meeting of the Glenboig Union Fireclay Company Limited … During the past year the company had acquired adjacent property and the works of Gartverrie and two subways were being constructed, one of which was intended to connect those works with Glenboig … Mr James Dunnachie elected as managing director …

23/03/1898 – Glasgow Herald – Joiners (2) wanted – steady men. Wages 30s per week. Apply to the Glenboig Union Fireclay Co Ltd, Glenboig.

20/09/1898 – Glasgow Herald – Bricklayers wanted. Wages 35s per week. Apply Glenboig Brickworks, Glenboig.

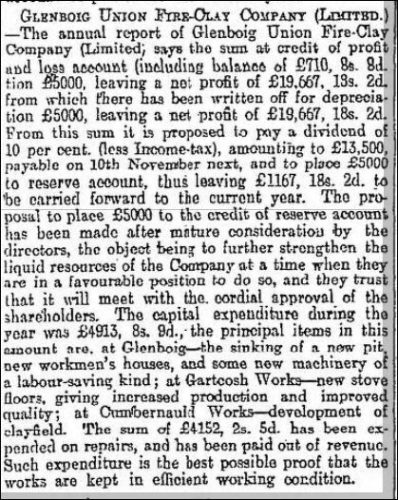

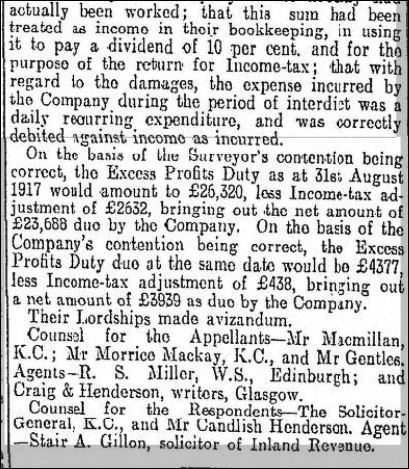

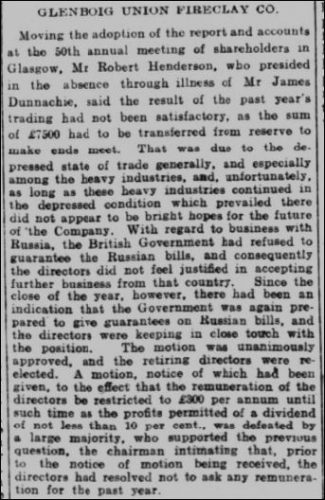

08/10/1898 – Dundee Courier – Glenboig Union Fire-Clay Company. The report of the Glenboig Union Fire-Clay Company for the year ending 31st August 1898 states that the sum at the credit of profit and loss account (including balance of £825 12s 6d brought forward from last year) is £16,210 8s 8d, from which there has been written off for depreciation £2000, leaving a nett profit of £14,2108s 8d. From this sum, it is proposed to pay a dividend of 10 per cent, (less income tax), payable on 10th November next. This dividend would amount to £13,500 and would leave a balance of £710 8s to be carried forward to the current year.

08/12/1898 – Daily Record – Issues have been ordered by the First Division in an action by Samuel Curran and others, the children of the late Robert Curran, labourer, Glenboig against the Glenboig Union Fireclay Company (Limited), Coatbridge, for £500 or £133 under the Employers’ Liability Act, as damages in respect of the death of the pursuers’ father, who on 10th May was run over by some waggons belonging to the Caledonian Railway Company (who are also called as defenders) and suffered injuries which led to his death. The defenders in both instances deny liability for the accident.

18/036/1899 – Airdrie and Coatbridge Advertiser – Settlement of Court of Session cases … as also the action by the children of the deceased Robert Curran against the same company (Caledonian Railway Company) for compensation for the loss of their father, who met his death in the Glenboig Fireclay Union Brickworks through a “flying shunt” in the clay-shed in May last. In both these cases the railway company have paid substantial amounts in satisfaction of pursuers’ claims.

Below – 31/08/1899 – Lloyds List – The daily register of British industries. The following classified list of British industries, containing the name of firms celebrated throughout the Kingdom for the various manufacturers for which they are associated, is compiled for the guidance of buyers in the different markets of the world.

Below – 11/10/1899 – The Scotsman – Glenboig Union Fireclay Company Limited annual report.

19/05/1900 – Bellshill Speaker – Motherwell and Bellshill Railway Bill … Mr James Dunnachie, managing director of the Glenboig Union Fireclay Company Limited, Cumbernauld, Gartcosh and Glenboig said his firm had the experience of competing lines at Glenboig and they found the competition resulted in a reduction of rates and various other benefits …

01/09/1900 – Kilsyth Chronicle – Shocking Accident Glenboig. A labourer named James Harper, (54). residing Southbank, Glenboig, has been run over and shockingly mutilated on a lye of the railway in the Union Fireclay Company’s Works, Glenboig. He had been in the act of cleaning a drain-pipe in the four-foot way when some waggons came upon him. He was dead when found.

and

The Glenboig Union Fireclay Company, Ltd., have been awarded a gold medal for their exhibits of fireclay goods at the Paris Exhibition.

1901 – Directory of clay workers – Glenboig Union Fireclay Company Limited. Works – Glenboig, Cumbernauld near Gartcosh. Head office – 48 West Regent Street, Glasgow. Fire bricks and furnace blocks, gas retorts and all types of settings, chimney cans, vent linings, ridge tiles, stable and causeway bricks, paving and byre crup tiles. T. add Glenboig, Glasgow. Tel 1009 National.

1901 – The clay miners went on a strike, broken only after 10 long months when the management brought in blackleg labour.

12/01/1901 – Dundee Evening Post – Lanarkshire miners to strike … Applications by Glenboig fireclay miners for permission to strike work for advance of wages was considered, and was agreed to obtain the decision of the county to striking work in this case also before deciding the matter next Thursday …

Below – Feb 1901 – Glenboig Advert.

17/07/1901 – Kirkintilloch Herald – Saturday night in the village – On Saturday last, when the “Journal’s” commissioner again visited the village, he found the strikers enjoying a well-earned relaxation after the excitement of the previous Wednesday. An equally contested football match was attracting the attention of younger bloods, while the scores of older men were at peace with the world in the collier like the recreation of sitting on their “hunkers” at the corners and doorsteps. Others and these, for the most part, were brick-workers, labourers, and blacklegs who were finding pleasure in partaking of “flowing bowl” in the village pub. The women folks, proud in the possession of their men’s ailment or dearly-bought wages were making preparations for a journey to the Brig to lay past the weeks provisions. Policemen patrolled the rows, and inwardly anathematized everything and everybody, for in these troublous days the lot of the Glenboig policeman is not cast in pleasant places. In the afternoon there were no indications of any trouble or disorder, but as the day advanced, and the visitation of the blacklegs to the village hostelry became very frequent and prolonged, things took a livelier turn. Suddenly the cry of “police” was raised, and a general rush was made to the Station Road. Here a sturdily-built workman, whose clothes were besmeared with blood, and whose head was a mass of cuts and bruises, was being borne home by a few boon companions. It transpired that he was a blackleg and that in return for some insolence he had been assaulted, somewhat brutally, by a person or persons unknown. The police set to investigate the matter, and the result of their inquiries was subsequently communicated to the “Journal” man. “I am afraid sir,” said the constable, “this incident must be written down in the books as another strike mystery. The assaulted person is an ex-army man, and a blackleg to boot. He has a very hazy recollection of what occurred, while his companions, who are his fellow-lodgers ad fellow-blacklegs, are equally as dense. judging from their present state of unfitness, it is now possible to get at the culprits from that side, and you can believe it’s most unlikely we’ll get anything from the strikers. Mind you I have the firm belief that the strikers know something about this. But scenes like these are of very frequent occurrence just now.” In the course of the conversation, the policeman remarked to our representative that his sympathies were entirely the strikers. “It’s a crying shame,” he added, “that men like that (pointing to an unwashed, unshaven, slightly elevated, and tattered parasite) should be sent here to disturb the peace and respectability of the village. Would you believe it, sir, but these men, although they have worked together for two months now, don’t know each other’s names. Some of them claim to be of English extraction, but I know different – they’re from the old country. I’m an Irishman myself, and I’m right down sorry that louts like these have been guilty of another injustice to Ireland. It would, indeed, be a pity if they openly acknowledged that they hailed from the Emerald Isle.” “And what about the Poles.” interjected our representatives. “It strikes me rather forcibly,” said the officer, “that the motto of the Poles should be for the hostile demonstration that took place. ‘nemo me imputie lacessit,” and for the reason that the strikers stand in mortal fear of these foreigners. The Glenboig Pole is constantly armed with a bottle, and if he’s interfered with, then a thousand pities on the poor devil who is daring enough to do it.” Proceeding to recapitulate some of the scenes at the evictions the constable held the opinion that the Sheriff officers had themselves solely to blame for the hostile demonstration that took place. Although these minions of the law had passed the sergeant of police at Glenbiog Station they never once thought of acquainting him with the object of their mission. “And I can assure you,” added the officer, in an undertone. “I was mightily glad to see them taking shelter in that hay shed yonder.”

24/08/1901 – North East Lanark Gazette – The Glenboig Dispute – In Glasgow Sheriff Fyfe on the bench, two respectable-looking men, named William Brown, senior., and John Leonard, were charged with intimidation in connection with the dispute at Glenboig Fire Clay Works. The indictment bore that the accused tried to compel certain men to desist from working at the clay works at Heathfield, by cursing and swearing at them and breaking some panes of glass. Both men pleaded guilty, and Mr Shaunessey, who appeared for them, explained that the case arose out of the strike that had been going on at Glenboig for some time. A number of Poles had been taken on to replace the men on strike, and this had exasperated the accused. One of them had been employed at the works for 32 years, and the other for 12 years. They were married men, one of them having 11 children and the other five. They were well-behaved and had never been in trouble before. Mr Brander, who prosecuted, said that the intimidation was very serious at the time, and several of the Poles against whom it was directed had, through fear, to take shelter beneath the beds in their houses. Sheriff Fyfe reminded the accused that the penalty for such a one-off as they had been charged with was three months imprisonment. There was a mistaken notion among trade unions that so long as no violence was used there was no intimidation. He would like to impress upon them that that was a mistake. No doubt the employment of Poles exasperated the men, and his Lordship was willing to make every allowance for them. At the same time, he pointed out that the Poles had a perfect right to work, and the accused might understand, and let their colleagues understand, that this kind of intimidation would not do. He would, however, impose a modified penalty in their case, and fined each of them £8. The fines were paid.

24/09/1901 – Dundee Courier – Glenboig Union Fireclay. The accounts of the Glenboig Union Fireclay for the year ending 31st August last after providing for the maintenance of works and all current charges, and including £1982 16s brought forward from the previous year show, subject to completed audit a gross profit of £17,902 5s 4d. The directors at their meeting today agreed to recommend to the shareholders at their annual general meeting to be held next month that the same be disposed of in the following manner:- For depreciation on capital expenditure£3000; in payment of a dividend at the rate of 10 per cent., £13,500 leaving a balance to be carried forward of £1402 5s 4d – £17, 902 5s 4d.