Northfield Brickworks, Shotts, West Lothian aka Shotts Brickworks. (Note – SBH – I am not certain but I believe the early brick kilns at Shotts were operated by the Shotts Coal & Ironstone Co. Then in 1910 the name changed to Northfield Brickworks when the Shotts Iron Company took over the site. Can anyone clarify this please?)

See also

Shotts Sand-Lime Brickworks, Shotts, North Lanarkshire. (Note – SBH – The 1985 publication ‘A survey of Scottish brickmarks’ suggests these were two different brickworks albeit they were situated very close together. Northfield – NS884600. Shotts Sand-Lime – NS884602).

Canmore

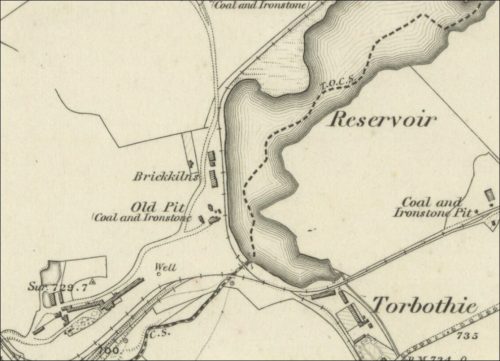

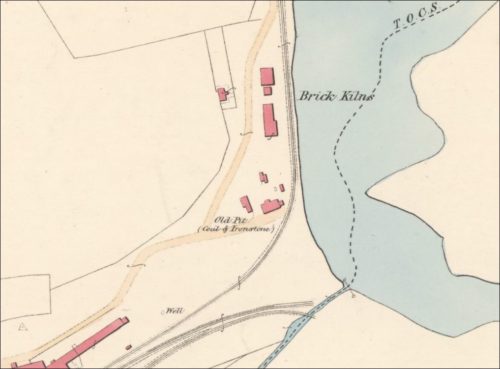

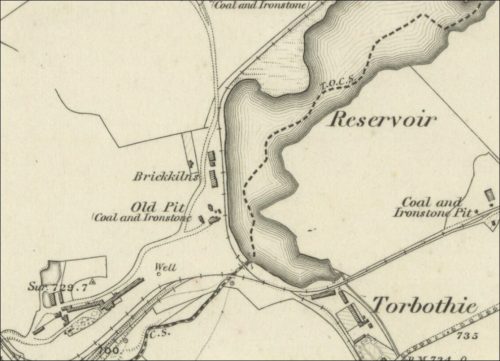

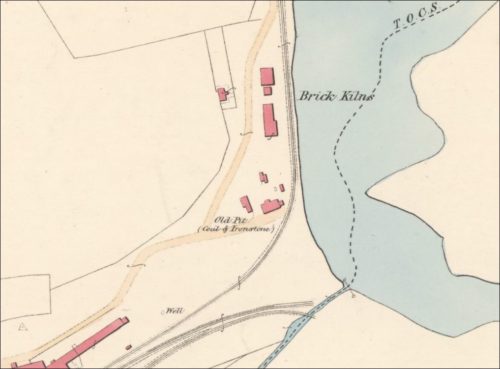

Below – 1859 – Shotts Brickworks.

Below – 1859 – Shotts Brickworks.

1872 – Shotts Coal & Ironstone Co (Composition bricks) Polkemmet. Walter Jamieson Manager.

Below – 06/03/1875 – Leith Burghs Pilot – Shotts Iron Company Depot, Leith … bricks of all descriptions can be supplied … W Galloway, Temporary Office, Admiralty Street, North Leith.

1882 – Shotts Coal and Ironstone Co, Composition brick maker. Polkemmet. Robert Jamieson Manager.

1886 – Shotts Coal and Ironstone Company, brick and tile makers, composition bricks, Polkemmet. Thomas Orr manager. (Page 942).

Below – 1897 – Shotts Brickworks.

Below – 1910 – Northfield Brickworks. (Located at the bottom of the map and marked as ‘kilns’).

1910 – Northfield Brickworks opened around 1910 and continued in business into the 1980’s. The kilns and offices had been demolished by 1992, and only the shower block, in use as a garage, remains.

06/05/1924 – The Scotsman – Electrical engineer’s visit to Shotts Works – Members of the West of Scotland branch of the Association of Mining Electrical Engineers to the number of 174 visited Shotts Works on Saturday at the invitation of the Shotts Iron Company (Ltd). The visit was instructive from the point of view of the application of electricity to the manufacture of iron, production of coal and the manufacture of bricks. The various sections of the works visited were the furnaces, the powerhouse, Northfield Colliery where all power including winding, is electric, the ore briquette works where fine ore is made into briquettes for feeding into the furnaces and the slag brickwork where a composite brick of slag and lime is made. At the luncheon, which was later provided by the board of directors, Mr Brown presided.

05/06/1933 – The Scotsman – Shotts Brickwork dispute – The stoppage of work which took place on Friday at the Shotts Iron Company’s Brickwork, when over 50 employees stopped work with a demand for increased wages was continued on Saturday. A deputation waited upon the works manager but he refused to meet with them to discuss the grievance until work had been resumed. This was reported to a meeting of the workers held on Saturday afternoon at which they decided to restart work today pending negotiations. The management announces that another factory will commence producing bricks today to help meet the abnormal demand and will give employment to 60 workers.

11/07/1933 – The Scotsman – Brickworkers strike at Shotts. The strike of 100 brickworkers at Shotts, which commenced on Friday, still continues. So far no meetings have taken place between the management and the workers to discuss the demand for wage increases. The management posted notices to the effect that employees who did not restart work on Saturday would be dismissed, but no restart was made. The strike is interfering with building operations.

13/07/1933 – The Scotsman – Shotts employees still idle. There is still no sign of a settlement of the dispute at Shotts Brickworks where 100 employees have been idle since Friday … The Union complain that the men were being paid 8 3/4d an hour compared with the standard rate of 1s 1/2d an hour and that the women and youths were paid 3 3/4d to 4 1/2d per hour …

14/07/1933 – Bellshill Speaker – Strike at Shotts – There is still no sign of a settlement of the dispute at Shotts Brickworks where 100 employees have been idle since Friday last. The National Union of General and Municipal Workers have written to Sir Godfrey Collins, Secretary of State for Scotland, directing the attention to the hold up of housing schemes due to the stoppage of work. Sir Godfrey Collins has written to the Minister of Labour who it is expected, will intervene with a view to bringing both parties together. The company state that they are willing to meet with workers but not the Union. Meanwhile, they have posted notices inviting contractors to make offers for taking over the production of the bricks under contract.

28/07/1933 – West Lothian Courier – Apparently there are no signs of a settlement in the Shotts brickwork dispute. It has been going on for about three weeks. The strikers have received from their union only two weeks strike pay. A number of the brickworkers are still at work and these are escorted from homes by the police.

28/07/1933 – The Scotsman – Shotts Brickwork strike ended – The strike at Shotts Brickwork, where 100 employees have been out for the past 19 days, has suddenly collapsed, and the workers have applied for reinstatement. Two days ago the workers rejected Trade Union advice that work should be restarted, but at a further meeting agreed without voting to resume work. They will be taken on as work becomes available.

09/09/1933 – Falkirk Herald – Falkirk foundry men’s visit of inspection to Shotts Works – Faith in the Future … The visitors then had an inspection of the two brickworks and they viewed the making of composition and grey brick from the company’s? products, the two works having a capacity of nearly 60,000 per day. Adjourning to the work offices, which are built entirely of Shotts grey bricks the visitors had the opportunity of witnessing an exhibit of the company’s various products – many varieties of coal, ironstone, pig iron, limestone, bricks, hydrated lime, grit etc … Mr Matthew Brown, Managing Director of the Company.

Below – 1940 – Northfield Brickworks.

20/12/1940 – The Scotsman – Shotts Iron Company Limited – Material improvement in cash position. Chairman Mr C. Augustus Carlow. Mr Matthew Brown retiring after 25 years with the company … Brickworks – In the early months of the war, the demand for bricks was poor but in later months the position improved very materially, resulting in a total production for the financial year of approximately 14 million composition bricks in addition to which there was a substantial increase in the sale of our Shotts grey slag bricks.

20/03/1942 – Wishaw Press – Returning home from work, Martha Allardice, 46 Springhill Road, Shotts was knocked down by a train consisting of a light engine and waggons. She had just left Northfield Brickwork where she was employed when the accident occurred. She was removed to the Royal Infirmary, Glasgow where it was found necessary to amputate the right leg.

1943 – A short history of the Shotts Iron Company Limited by Augustus Muir … During the early part of the war, the brickworks both at Roslin and Northfield were kept busy. The

demand was mainly for the building of new factories, defences, air-raid shelters and other emergency work, but in the middle of 1942 orders were falling off. By the end of that year, when brickworks were closing down all over the country, it was realised that the Company’s entire brickmaking plant would soon be out of action. On 2nd July 1943, the Roslin works were closed, with over 1,500,000 bricks lying unsold, and the Northfield works were shut down in September of that year. Both remained under care and maintenance for the duration of the War … (P56).

28/08/1945 – Daily Record – John Mulvey, brickworker, Torbothie Road, Shotts lost a finger while at work at Northfield Brickwork yesterday. He was removed to the Edinburgh Royal Infirmary.

1947 – 1969 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests the works were operated by the National Coal Board during this time.

Below – 1957 – Northfield Brickworks.

1961 – 1962 – Directory of British Clay Products and Manufacturers – Northfield Brickworks. (See NCB Scottish Division, Central East and West area). Common bricks. Trade name ‘Shotts’.

08/02/1963 – West Lothian Courier – National Coal Board. Central Area review. 1962 – The Central Area was formed at the beginning of the year by amalgamating the Central East and Central West areas … Brickworks – There are six brickworks operating in this area, namely Barbauchlaw, Blantyreferme, Gartshore and Gateside, Newton and Northfield. Some 54 1/2 million bricks were produced during the year. These works now come under the Brickworks Executive. which was formed earlier this year …

03/04/1964 – West Lothian Courier – There was no improvement this week in the supply of bricks to the County Council housing scheme at Springhill. A brick scarcity has stopped weekend work by bricklayers and slowed down the rate of progress at the site. An official of the builders, Crudens Ltd, said that lorry loads of brick had to be brought from as far as Dumfries to keep the “brickies” supplied. The official attributed the shortage to the mild winter weather, which, in contract to last year, had caused no hold-up in the building industry. ” Brickworks have no stocks left.” said the official. It is ironic to think that the Springhill site overlooks the N.C.B. brickworks at Torbathie and yet cannot get an adequate supply.

14/05/1965 – West Lothian Courier – National Coal Board. Brickworks executive. Kiln emptiers and general labourers urgently required at Northfield Brickworks, Shotts. Please apply to the works manager, Northfield Brickworks.

27/08/1965 – Wishaw Press – Deaths. Suddenly at Northfield Brickwork as a result of a shooting incident on 17/08/1965, James Stark, beloved husband of Lilias Stark, 16 Eskdale Place, Dykehead, Shotts.

Below – 10/11/1965 – The Glasgow Herald.

08/04/1966 – West Lothian Courier – National Coal Board. Brickworks executive. Kilnburners experienced in burning common bricks in Hoffman kiln. Good conditions of service and pay. Apply works manager, Northfield Brickworks, Shotts.

30/09/1966 – Wishaw Press – NCB fined. A fine of £50 was imposed in Hamilton Sheriff Court on Tuesday on the National Coal Board Brickworks Executive, Northfield Brickworks, Shotts, for failing to fence properly a dangerous part of machinery at the conveyor belt between June 7 and 21. It was stated that the conveyor belt carrying the bricks jammed and a woman worker placed her hand in to remove the obstruction. At the same time another worker switched on the engine and the woman’s hand was caught between the belt and conveyor.

26/04/1968 – Wishaw Press – Situations vacant. National Coal Board. Brickworks executive. Scottish region. Northfield Brickworks. Maintenance engineer in brick making machinery is required for our Northfield Brickworks. Good rates of pay and excellent conditions of service. Applications to be made to the works manager, Northfield Brickworks, Shotts.

02/08/1968 – Wishaw Press – National Coal Board. Brickworks executive. Northfield Brickworks. General operatives for dayshift and nightshift. Good rates of pay and excellent conditions of service. Apply The manager, Northfield Brickworks, Shotts.

1969 – 1984 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests the works were operated by the Scottish Brick Corporation during this time.

09/05/1969 – West Lothian Courier – Scottish Brick Co Ltd require a nightshift foreman at Northfield Brickworks, Shotts. Applications are invited from men experienced in the control of men. It is not necessary to have brickworks experience but this would be an advantage. Applications in writing to the Production Manager, Scottish Brick Co Ltd, Gateside Brickworks, Cambuslang, Nr Glasgow.

05/12/1969 – West Lothian Courier – Firemen were called out last Friday afternoon to deal with an outbreak of fire at the Northfield Brickworks. The blaze started when a fire was kindled to thaw out frozen pipes. A set of wooden doors and adjoining property were set alight. The firemen quelled the blaze before any serious damage was caused.

15/05/1970 – Wishaw Press – Police are investigating the theft of 5 sets of brass bushes, valued at approx £140, from Northfield Brickworks at the weekend.

09/04/1971 – Wishaw Press – Scottish Brick Company Limited require experienced kiln burners at their Shotts Brickworks. Applicants should be made to the manager, Northfield Brickworks, Shotts.

12/10/1973 – Wishaw Press – Kiln burner. A kiln burner fully experienced is required for our Northfield Brickworks, Shotts, Lanarkshire. Conditions of service are good. Applicants should call for an interview at the works between 9 am and 3.30 pm Monday to Friday next week.

Below – 14/11/1975 – Wishaw Press – Advert for the Scottish Brick Co and promoting bricks manufactured at their Holytown and Northfield Brickworks.

13/04/1979 – Wishaw Press – Reference to the employees of Northfield Brickworks sending cards etc to the family of an employee who died in a non-work-related accident.

1984 – The 1985 publication ‘A survey of Scottish brickmarks’ suggests the works were operated by the Glasgow Iron and Steel Company Limited from this time until they closed.

2012 – History Group Bulletin – Northfield Brickworks, Shotts.

As a young boy growing up in the High Street between 1950 and 1960, I remember it was a busy thoroughfare with heavy and light transport trundling up and down from an early hour. Similarly, there was also a steady stream of workers making their way to various jobs in the foundry, workshops, Northfield Colliery and Northfield Brickwork. My interest in Northfield Brickwork was stimulated by my dad as he started as a young lad in the ‘white brickwork’ and moved to Northfield Brickwork on his return from the army. I always looked forward to our evening walks, where the ‘Voe’ was a popular destination. The remnants of the ‘white brickwork’ were still evident at this time, as was the slag hill which provided the material to produce the distinctive finished grey brick for general building. Although Northfield Brickwork was accessed from the High Street, it was located close to the bottom of Charles Street in Torbothie. At this time, Northfield Brickwork was still in production, making an orange coloured common building brick made from crushed ‘blaes’. Although I was never employed by Northfield Brickwork, as an apprentice electrician with the Central workshops I was involved with ongoing maintenance and repairs. Northfield Brickwork started off as a briquette work as far back as 1896 and was owned by the Shotts Iron Company. The then furnace manager saw a niche to make a useful product from the iron ore dust, which at that time was considered waste. Subsequently, he took out a patent to process the dust and a plant was built to produce iron ore briquettes. These briquettes were then added to the furnace, in turn, increasing the yield of iron ore. Demand for iron ore decreased and thus, the need for iron ore briquettes. Modifications to the existing machinery in the briquette work were made to enable the production of building bricks. Northfield Brickwork consisted of two pan mills, three brick presses and two kilns. The process began with ‘blaes’, a pit bing waste mainly from Northfield Colliery, which was transported by railway wagons to the two pan mills. On arrival, men would then shovel the ‘blaes’ into the pan mills where it was crushed by two large rotating rollers into a fine dust. This fine dust passed through the perforated floor of the mill into a collection pit. Bucket

elevators then collected and lifted the fine dust from the pit to an area above the press machines, known as the loft. From here the dust went down into a mixer where it was mixed with oil and water before moving onto a rotating table which gave the brick its initial rough shape. The water used for the mixing process was pumped from the Voe by a D10 Mono pump housed in a small brick building next to the by-wash. Exiting from the turntable, the rough pre-formed brick was pressed to size and the ‘Shotts’ stamp imprinted. Although they were shiny black in colour, they were termed ‘green’ bricks. From here the ‘green’ bricks were taken to the kilns where workers, known as setters, built them in a specific fashion to allow the firing flame to pass through the stacks, commencing the process of turning them into the finished brick. The kilns used in this process were modelled upon the Hoffmann design. They were fired with beans of coal and access ports of the top of the kilns provided a means to control the firing of the bricks. The brick firing areas were arched in shape and controlled by dampers linked to a ventilation fan. As the kilns had no individual chambers, this firing process was continuous.

Once the bricks were placed inside the kilns, the entrance doors were bricked up and daubed with fire clay to seal the chamber. It was then up to the kiln burner, who worked above the kilns, to observe conditions and fire it accordingly. The kiln burner was responsible for ensuring the fire passed into the next kiln of bricks ready to be fired. Interestingly, the fire was lit after the Fair holidays and continued to burn until the start of the following Fair holiday. When the flame had moved on, workers, known as strippers, removed the bricks from the kilns. This task was a hot and dusty occupation. The bricks were then loaded directly onto lorries from the kilns and transported to customers in places such as Cumbernauld, Dunblane and as far afield as Campbeltown. Surplus bricks were also stored in the stockyard, which was a good yardstick for determining the state of the building industry. In the 1960s, the internal rail network delivering the raw material was replaced by road transport necessitating improvements to the established system. A pre-crusher conveyor system was installed transporting the ‘blaes’ on conveyor belts to a crusher, which reduced its size before entering the pan mills. The internal transport of the bricks was also improved by the installation of another conveyor system, which transported the "green" bricks from the presses into the kilns. As a result of an influx of finished brick from England, the demand for common brick declined and so too did the demand for Shotts brick. The production of common brick at Northfield Brickwork slowly declined until its closure in the mid-1980s. The closure of the brickwork was a great loss to the workers, not only as a means of employment, but also the loss of friendships and social status associated with working within a local production environment. It was once said that ‘Shotts lit the world’ but it might also be said that ‘Shotts built the world’ through the production of a quality brick product.

Bobby Fleming

Slag Hill – Locally known as the ‘Crusher’ it used slag from the Shotts furnaces crushed to produce railway ballast.)

Below – Video entitled Shotts – Dirty Old Town. This features the derelict brickworks