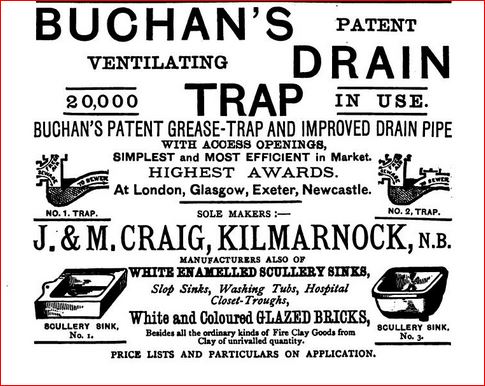

Below – 1883 – Architects and Contractors handbook

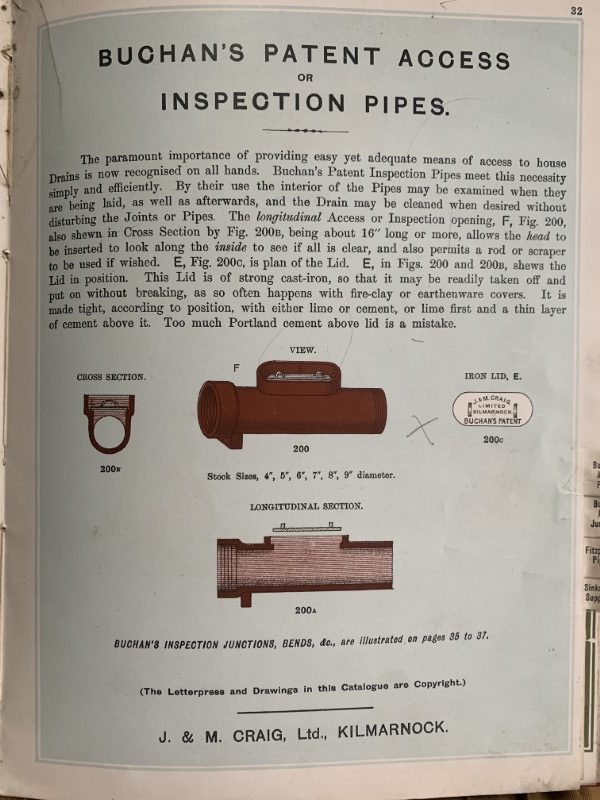

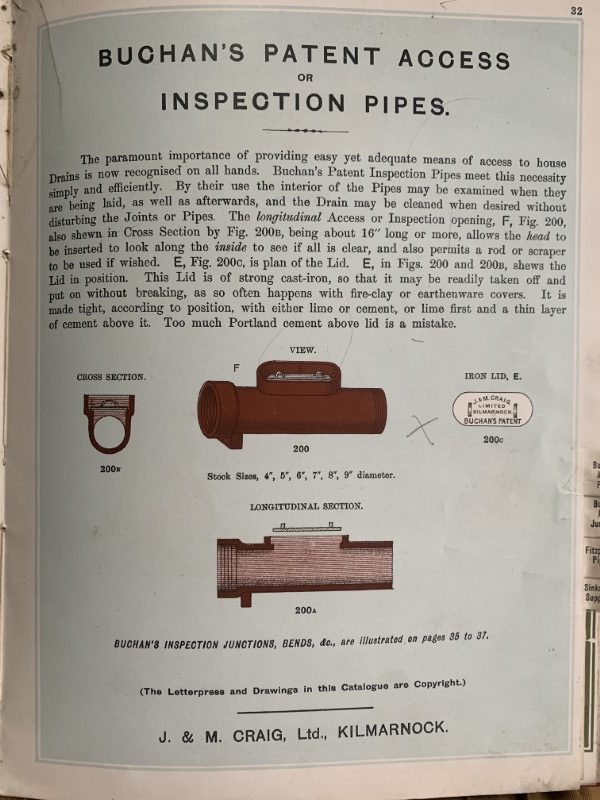

Buchan’s Patent Improved Drain Pipes.

J. & M. Craig, Kilmarnock. These pipes are moulded with a block or seat at the faucet end, which allows room for making the joint properly, and prevents the pipes from rolling, and the joints being broken before they are set. Access pipes are made with openings 18 in. long, which readily allow the admission of a rod or scraper, and facilitate the examination of the drains. The movable cover may be secured with mortar or cement.

Buchan’s Patent Ventilating Sewage Gas Trap.

A stoneware syphon trap with a vertical dip, and of a form that will quicken the passage of soil into the sewer. A provision is made on the house side of the trap for the admission of fresh air into the drains and on the other side of the trap, a means of clearing put the trap if required, or for ventilating purposes.

Below – 13/08/1883 – Aberdeen Press and Journal – Buchan’s Patent infringements by Hurlford Fireclay Works and Caledonia Fireclay Works.

14/06/1884 – Kilmarnock Standard – One of the reasons why Kilmarnock has not felt the depression of trade so severely as some other places, is the variety of the trades carried on in the town. Our working people do not depend entirely on one branch of manufacture, so that though there should be a collapse, greater or less, in one branch, others may have full employment. The practical extinction of the once extensive calico-printing industry was more than made up for by the development of the iron trades, and the growth of the wincey and tweed manufactures has gone far to fill the blank caused by the decline of carpet weaving. It is gratifying to notice the introduction of a new branch of industry in any direction, but more so when it points to the increased business capacity of a firm that has already acquired considerable fame in another direction, to some extent akin to the new undertaking. Within the last few weeks the Messrs. J. and M. Craig, Hillhead Works, have inaugurated the pottery trade, or manufacture of white earthenware goods of various kinds and qualities. The other branches of their Fire Clay Works have been enormously extended of late, and now by their enterprise and foresight, they have introduced a new branch of clay manufacture, and one which we hope will prove the nucleus of a business equally extensive with that hitherto so ably carried on. This week we had the pleasure of a visit to the new works, and by the kindness of Mr Taylor, the energetic manager, and Mr McLauchlan, the foreman of this branch, were initiated into some of the mysteries of the pottery manufacture.

The new works are situated to the east of the Fire Clay Works and are in the form of a parallelogram, 130ft. by 120ft., the workshops and warehouses lying on the east and west sides, with a central roadway between. The raw material, which consists of ball clay, Cornwall stone, China clay, and flint, is brought from the South of England by sea and rail, and we understand Messrs. Craig have such facilities for carriage that they will be able to compete favourably with Staffordshire (the great seat of the pottery trade), as well as with Glasgow and Ireland. They have also been able to secure the services of a competent foreman, and workmen from Staffordshire; Belleek, Ireland; and Glasgow so that there is every guarantee of the quality of their goods.

The clay and other materials are first carried to the “slip house,” and there ground into a very fine powdery paste by means of a revolving granite stone. It is then conveyed into separate tanks, run into a large vat, and mixed in a liquid state in the proportions necessary for the quality of the goods. These are called “Blunging pans.” The mixed clays are then passed through a fine sieve, by means of machinery, and taken up by force pumps into the “clay press,” which is strongly bound and screwed to sustain a pressure of 901bs. to the square inch, and which contains thirty leaves or cells. The mixture is here passed through strong cotton cloth made especially for the purpose. The water is thus runoff and the clay collected in bags containing about l cwt. each, or about one-and-a-half tons in all. This can be charged and emptied three times daily. In this state, it is like ribbed webs two feet wide and an inch thick. These are put in the ” pug mill,” where the clay is cut by knives placed like a steamer’s screw, and the purpose is to drive out the air, make it uniform in consistency, and quite solid. This operation is done twice, and the clay is then ready for manufacture.

We now turn to the modelling shop, where the moulds of stucco are fashioned. This is, of course, a critical operation, for on the quality of the mould will depend to a large extent the beauty of the article as to shape. From the modelling shop, we go to the making shop, where all the different articles are fashioned. We saw the whole process in the manufacture of an ewer of antique shape. The bottom of the ewer is first made; then the body in two parts, a gauge giving it uniform thickness; when the two parts have been brought together the inside is smoothed with a fine sponge, wet, and then run over with a piece of India-rubber sheet, the jug revolving on a pivot. The bottom is then put on and a strong strap drawn down on the outside of the whole. In this condition, it is placed on a shelf for about a couple of hours until it is ready for the drying stove. The handle is made separately and attached. The heating stove is in the centre of the premises and entered from both sides of the working section of the room. It is heated by exhaust steam passing through a series of pipes, to the extent of about 100 degrees, according to the quality of the goods, and the same test is applicable to the time the articles remain in it. Here, as elsewhere, they require to be tenderly handled, as they are easily soiled or damaged. This shop is 60 feet by 37. On leaving the drying shop the articles are taken to the other side of the parallelogram and put first into the “biscuit kiln.” Each article is placed in a “seggar,” which is made of fire-clay, and the seggars are piled in tiers or bings 25 in height and numbering in all 1,250. When the oven is filled the aperture is closed by means of fire-clay, and the fires lighted. Here they remain in “white” heat for about fifty hours. Small openings are left to show when the material is sufficiently burned. When properly “biscuited,” the goods are warehoused, examined piece by piece, and all defective ones laid aside. They are then taken to the dipping house, in which each is immersed in the glazing vat, after which they are carried to the “glost” or glazing kiln, where they are put in “seggars” arranged in tiers as in the biscuit kiln, and allowed to burn for about eighteen hours. It takes from thirty to forty hours to cool this kiln and clear the goods. They are then taken to the “glost” warehouse, where they are examined, as in the biscuit warehouse, and all defective pieces laid aside. The goods are now ready to be warehoused as stock, or packed in crates, placed in wagons in the lye that has been carried to the side of the new works, and sent thence to their destination. It will thus be seen that the raw material enters one end of the parallelogram and comes out at the other end, a finished product.

All that we have described applies to the purely white earthenware. When the goods have to be gilded, marbled, or enfigured, they are taken upstairs to a separate branch of the establishment. To be marbled the pattern is first put on a piece of tissue paper from a copperplate impression, and then transferred to the article by rubbing. The pattern adheres to the dish, and the superfluous stuff is washed off. The decorations by painting are done by the hand, and so is the gilding, the articles being placed on a revolving stand. We much admired the steadiness and dexterity with which this artistic work was done by the lady employed in its execution. Only practice could produce such fine work. All the decorated goods are taken to a small kiln, where heat is applied for six to eight hours, according to the class of goods. They are then put in sets, ready for the market.

The whole of the machinery in the works is moved by a very handsome horizontal engine of fully 20-horse power, made by Messrs. Grant, Ritchie, and Co. The engine has a patent governor, exceedingly sensitive, and we believe the only one of the kind in town. Close to the engine is the house where the glaze is made, but as the process is generally deemed a secret we did not inquire into it. It is not our intention to give a list of all the articles made in the works. Suffice it that the chief are, cabinet stands for house and ship use in white, marble, or gold; water-closet basins; plugs; toilet ware of a great variety of shapes and patterns in white, printed, enamelled, and gilt. There are also jugs of diverse patterns, many of them of antique design; cheese covers, jelly shapes, and others—all of them, in so far as our unpractised eye could judge, of fine finish and quality. Among the specialities are two articles which may be particularly mentioned, as Messrs. Craig are the only parties who have the right to make them—a right acquired from the patentee. One of them is called “Armstrong’s patent self-flushing urinal.” The water rises to a certain height in the small basin, and when that is reached an automatic flush takes place and carries off the contents. The basin fills again and the same process is repeated with the utmost regularity. The urinal being also trapped, no bad smells come from the drain. The other article is termed “Shields’ patent flush-out closet and trap combined.” It would need a diagram to describe the construction of this article. Suffice it that, as in the other, there is always from one to two inches of water in the pan, so that it is kept always clean. In both of these, the useful and the handsome have been well combined, and a considerable demand is expected for them.

We could not leave the works without wishing the Messrs. Craig every manner of success in their new undertaking. It is but the germ of what we trust will ultimately develop into an extensive and profitable branch of industry, giving employment to hundreds, enlarging the trade of the town, and yielding that profitable return which is expected and desired. If business tact, upright dealing, energy, and determination, coupled with a due regard to the rights and comforts of those in their employ, should command success, then the new branch of local industry set on foot by Messrs. J. and M. Craig will ere long be a flourishing one.

01/10/1884 – Freemans Journal – The Sanitary Congress and Exhibition Dublin.

Medals and starred certificates.

J & M Craig, Kilmarnock – for white enamelled fire clayware for sinks.

Certificates:

J & M Craig, Kilmarnock – For Buchans disconnecting trap.

Deferred exhibits:

J & M Craig, Kilmarnock – Washing tub.

J & M Craig, Kilmarnock – Shields flush out w/c.

J & M Craig, Kilmarnock – White enamelled fire clay laundry trough.

Below – 08/05/1885 – Ardrossan and Saltcoats Herald – J & M Craig, Longpark Pottery, Kilmarnock advert.

1886 – John E Calver, brickmaker, (J & M Craig), 23 Hill Street, Kilmarnock.

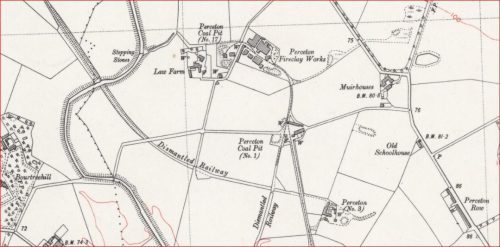

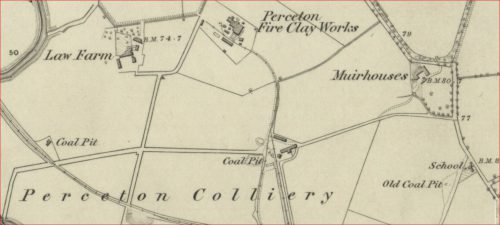

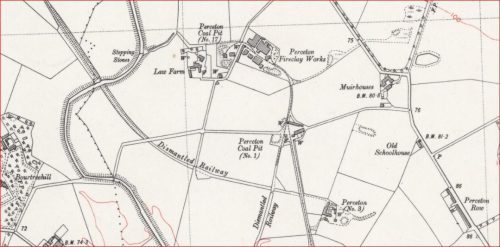

1886 – J. & M Craig, manufacturers of fire bricks, paving tiles, vitrified pipes, cattle troughs, chimney cans, flower vases, and other fire clay goods, also all kinds of sanitary & plumbers earthenware, Hillhead & Perceton Fire Clay Works, Longpark Pottery & Hillhead Colliery. (Page 235).

1886 – James Craig Esq, J.P, – Fire brick manufacturer, (J&M Craig), Deans Mount, London Road, Kilmarnock.

James Craig – Fire brick manufacturer, (J&M Craig), Cessnock Bank, Dundonald Rd, Kilmarnock. (Page 235).

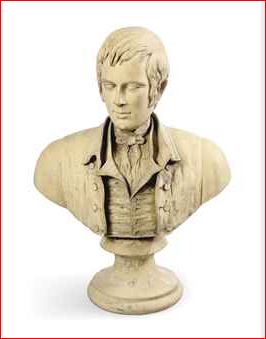

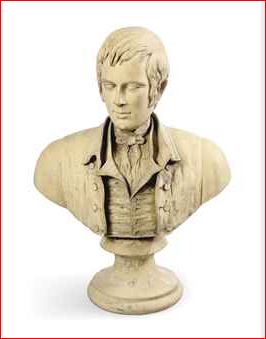

28/05/1886 – Ayr Observer – International Exhibition, Edinburgh … The most numerous c.ass of exhibits is that of fire clay and pottery work, exhibited by Messrs J. & M. Craig, the Bourtreehill Fire Clay Company, Messrs J. & R. Howie. In this class of goods, the first-mentioned firm are strong exhibitors. They have (court 6, No.827) a very large stand of fireclay and enamelled goods from their works at Hillhead and Perceton, and of sanitary pottery &c., from Longpark. Of enamelled work, they have an extensive collection, for sewerage and other sanitary purposes. In white earthenware, sanitary pottery, and also in some terracotta busts, notably of Sir Walter Scott, they are conspicuous. Ranking next to them in fire clay work for sanitary uses is the Bourtreehill Fire Clay Company, which exhibits among other appliances, Miller’s patent drain traps, Cowan & Miller’s patent grease traps and Arnistrong’s patent inspection junctions for drain pipes, the last of a which is exceedingly ingenious in contrivance and will probably be of great use for sewerage. The Edinburgh agents of the Bourtreehill Fire Clay Company, Messrs William Clunes & Co, Leith Walk, Edinburgh, show some beautiful work in Scotch and Irish marble, consisting of three chimneypieces and a floor of marble mosaic. The central chimneypiece is made of Blanc. P. marble, with its columns, panels and other enrichments in Glen Tilt and other Scotch marbles of various colours. That on the left hand is of Galway black marble with panels in Portsoy serpentine. The principal feature, however, is the marble mosaic floor, laid out in beautiful patterns of white, grey and black marble and entirely composed of Scotch material taken from quarries in the counties of Argyll, Inverness, Banff and Perth. In all four exhibits, the different colours of the marble have been most tastefully arranged, the predominant ones being black and different shades of grey. An important feature is that, with the exception of the Galway, the Sienna and the Blanc P. marble, the whole of the material used is Scotch. Messrs J. & R. Howie, Hurlford Fire Clay Works, Kilmarnock have two stands of enamelled work and fireclay sanitary appliances, one of them being outside in the grounds. Among other useful exhibits of theirs are their well known ventilating traps which are used in Balmoral and elsewhere …

29/05/1886 – Irvine Herald – Ayrshire Exhibitors at the International Exhibition … J. & R. Howie, Hurlford Fireclay Works, Kilmarnock, show at their stand white enamelled baths, sinks, washtubs and milk coolers, together with enamelled ventilating sanitary traps, horse mangers, cattle troughs, patent filters, and several kinds of bricks manufactured at their works. Perhaps the largest collection in this section is that of M & J. Craig, Hillhead and Perceton Fireclay Works, and Longpark Sanitary Pottery, Kilmarnock, whose exhibits are of the most miscellaneous description. The greater part of them have more or less connection with the subject of sanitation, but besides these are many other useful and ornamental articles which have been turned out from the fire-clay works and pottery of the Kilmarnock firm The Glenfield Company, Kilmarnock, in addition to sewerage fittings have on view a very fine collection of water work fittings. The Bourtreehill Coal Company, Dreghorn, Ayrshire, show enamelled fireclay goods and several patent drain traps …

28/07/1886 – Glasgow Herald – International Exhibition Edinburgh – Messrs J and M Craig, Kilmarnock, have a large display of fireclay goods suitable for various sanitary purposes, and many of them have obtained awards at other exhibitions. The most important articles are the Buchan traps and drain pipes, which are intended to, and in the opinion of many professional men, they really do, meet the requirements of sanitary science in its relation to the drainage of houses. Among the other goods shown by the firm are enamel sinks, bricks, closets, &c, besides toilet ware, jugs, &c

26/10/1886 – Edinburgh Evening News – International Exhibition – J & M Craig, Kilmarnock – Gold medal – Whole exhibit of fireclay goods especially Dunfermline ornamental ware.

J & M Craig, Kilmarnock – silver medal – drain pipes as laid and tested.

J & M Craig, Kilmarnock – bronze medal – Buchans Eclipse WC.

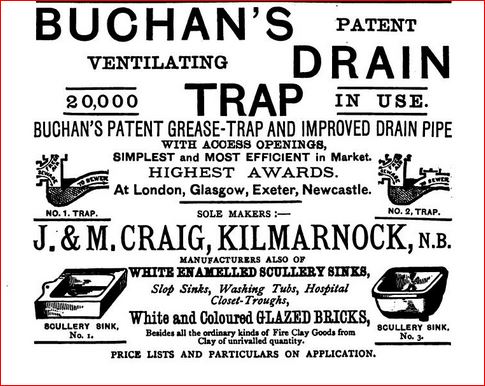

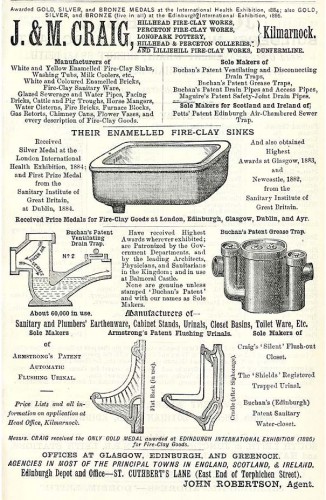

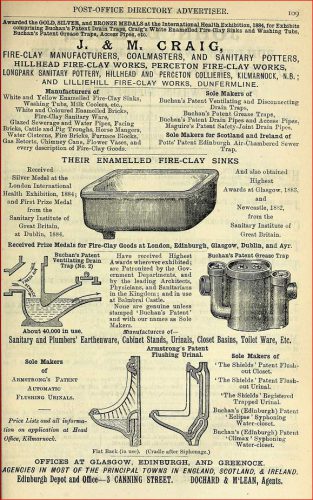

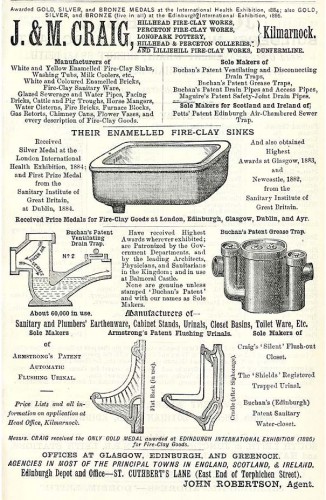

Below – 1886 – 1887 – J & M Craig, Kilmarnock advert.

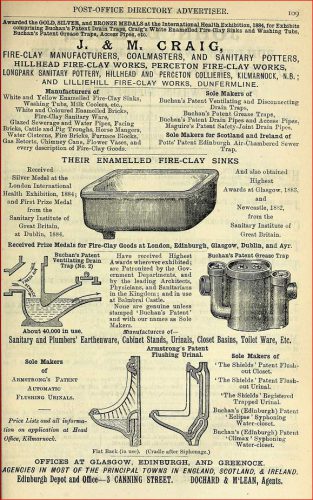

Awarded the Gold, Silver and Bronze medals at the International Health Exhibition 1884 for exhibits comprising Buchan’s patent drain traps, Craig’s white enamelled fire clay sinks and washing tubs, Buchan’s Patent grease traps, access pipes etc

J & M. Craig, Fire clay manufacturers, coal masters and sanitary potters – Hillhead Fire Clay Works, Perceton Fire Clay Works, Longpark Sanitary Pottery and Perceton Collieries, Kilmarnock, N.B and Lilliehill Fire Clay Works, Dunfermline.

Sole Makers of

Buchan’s Patent Ventilating and Disconnecting Drain Traps,

Buchan’s Patent Grease Traps,

Buchan’s Patent Drain Pipes and Access Pipes,

Maguire’s Patent Safety-Joint Drain Pipes.

Sole Makers for Scotland and Ireland of Potts’ Patent Edinburgh Air- Chambered Sewer Trap.

Manufacturers of

White and Yellow Enamelled Pire-Clay Sinks,

Washing Tubs, Milk Coolers, etc.

White and Coloured Enamelled Bricks,

Fire-Clay Sanitary Ware,

Glazed Sewerage and Water Pipes, Facing

Bricks, Cattle and Pig Troughs, Horse Mangers,

Water Cisterns, Fire Bricks, Furnace Blocks,

Gas Retorts, Chimney Cans, Flower Vases, and every description of Fire-Clay Goods.

Their enamelled fire clay sinks received Silver Medal at the London International Health Exhibition, 1884 and First Prize Medal from the

Sanitary Institute of Great Britain at Dublin, 1884.

And also obtained Highest Awards at Glasgow, 1883 and Newcastle,1882,

from the Sanitary Institute of Great Britain.

Received Prize Medals for Fire-Clay Goods at London, Edinburgh, Glasgow, Dublin, and Ayr.

Buchan’s Patent have received highest awards wherever exhibited and are Patronized by the Government Departments, and by the leading Architects,

Physicians, and Sanitarians in the Kingdom; and in use at Balmoral Castle.

None are genuine unless stamped ‘Buchan’s Patent’ and with our names as Sole Makers.

Buchan’s Patent Grease Trap and Buchan’s Ventilating Drain Trap (No. 2)-

About 40,000 in use.

Manufacturers of – Sanitary and Plumbers’ Earthenware, Cabinet Stands, Urinals, Closet Basins, Toilet Ware, Etc.

Sole makers of Armstrong’s Patent Automatic Flushing Urinals.

Price Lists and all information on application at Head Office, Kilmarnock.

Sole Makers of

‘ The Shields ‘ Patent Flushout Closet.

‘ The Shields ‘ Patent Flushout Urinal.

‘The Shields ‘ Registered Trapped Urinal.

Buchan’s (Edinburgh) Patent ‘ Eclipse ‘ Syphoning Water-closet.

Buchan’s (Edinburgh) Patent ‘Climax’ Syphoning Water-closet.

Offices at Glasgow, Edinburgh and Greenock. Agencies in most of the principal towns in England, Scotland and Ireland. Edinburgh Depot and Office— 3 Canning Street. Dochard and McLean. Agents.

24/12/1887 – Glasgow Herald – Yesterday morning between two and three o’clock one of the large wooden sheds in which work is carried out at the brickwork of Messrs J & M Craig, Perceton, was discovered to be on fire. Fortunately, the efforts used to confine the fire to the shed in which it originated were successful, but in addition to the structure itself, a number of valuable moulds were destroyed. It is estimated that the damage done will exceed £500.

1888 – Alexander Murray (Agent for Messrs. J. & M. Craig), Perceton and Hillhead Fire Clay Works, Kilmarnock. Office, 98, Commerce Street. For upwards of twenty years the well-known Hillhead and Perceton Fire Clay Works, Kilmarnock, of which Messrs. J. & M. Craig are the proprietors, have had a depot and warehouse in this city, Mr Alexander Murray of the above address being the representative of the firm. Mr Murray, does a very extensive business, in fire clay goods, lime, and cement. The well-known sanitary ware manufactured by Messrs. J. & M. Craig has long occupied a prominent and well-sustained position in the trade. All the latest improvements have been introduced into its construction, and the well-known and durable character of their fire clay has made this ware very popular with sanitary engineers, architects, and builders.

The stock held by Mr Murray embraces glazed sewerage pipes, patent traps and cesspools, grease boxes, white and yellow enamelled sinks, washtubs, and milk coolers, white and coloured enamelled bricks; also Buchan’s patent, sanitary appliances, including the famous drain ventilating traps, of which about 70,000 are now in use all over the country, and in America, the Colonies, &c. ; patent trap fittings, patent improved drain-pipes, patent grease traps, as used at Balmoral Castle, the Highland residence of the Queen; and Buchan’s anti-bell traps, Maguire’s patent safety-joint drain pipes, and Potts’s patent Edinburgh air-chambered sewer trap. Buchan’s patent drain traps awarded a gold medal at the International Health Exhibition, London, 1884, and highest awards at the other recent Sanitary Exhibitions. Potts’s patent trap was also awarded a gold medal at the International Health Exhibition, London, 1884, and at the Edinburgh International Exhibition, 1886. Messrs. J. & M. Craig received the only gold medal awarded for fire clay goods.

Mr Murray is also agent for Messrs. Craig’s, Longpark Sanitary Pottery, Kilmarnock, at which they manufacture sanitary and plumbers’ earthenware, including cabinet stands, plug and tip-up basins, urinals, water closets, toilet ware, &c., the “Silent” flush-out closet, the Shield’s flush-out closet, and Armstrong’s patent automatic flushing urinals.

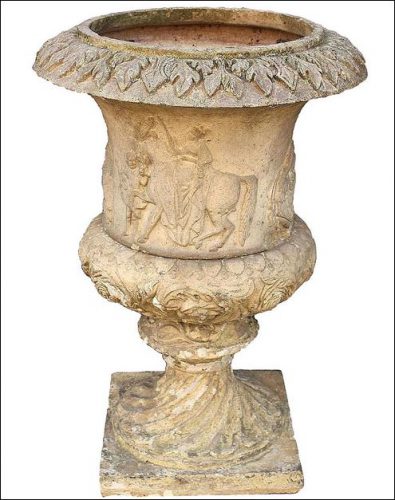

20/04/1888 – Fifeshire Advertiser – Glasgow Exhibition – Lilliehill Fire Clay and Terra Cotta Works-The Messrs L & M. Craig, Lilliehill Fire Clay and Terra Cotta Works, Dunfermline, are to be exhibitors at Glasgow of a large assortment of terra cotta statuary and vases. A good deal of really artistic work will be displayed in the moulding and adjuncts of the figures. The same firm will also send an arrangement of their Kilmarnock enamelled bricks, washtubs, &c.

25/08/1888 – Lennox Herald – International Exhibition, Glasgow – Sanitary section – Messrs J and M. Craig, Kilmarnock, show sanitary appliances, consisting of baths, water closets, sewage pipes, traps, acid tanks, bricks, toilet ware, &c., all beautiful in design and decoration. On this stand are two statuettes, in fire clay, of Professor Simpson, Edinburgh, which for the fineness of skin and quality are in no way inferior to the best Parian.

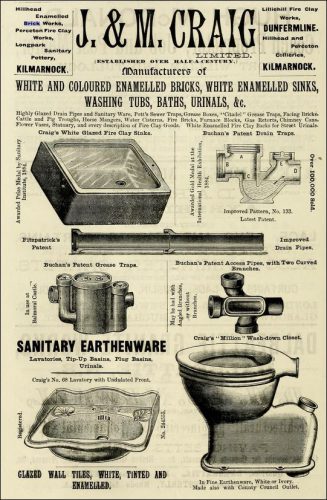

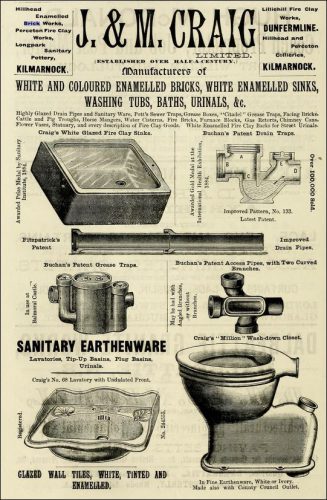

Below – 1889 – 1890 – J & M Craig, Kilmarnock advert.

Below – 18/05/1889 – Dundee Courier – (See below entry dated 25/10/1889). Court case over the quality of J & M Craig water pipes.

29/06/1889 – The Record and Guide Vol 43, No. 1111- Advert – Glazed or enamelled brick. Messrs. J. & M. Craig, of Kilmarnock, Scotland, have appointed Messrs. Charles R. Weeks & Brother, of New York, their Sole Agents for the United States. Our White and Colored Glazed Brick are unsurpassed by any others made in Great Britain. Samples and prices may be obtained from the office of our Agents. Charles R. Weeks & Brother, 74 Murray St., New York.

Below – 25/10/1889 – Dundee Advertiser – Court case against J & M Craig – dismissed.

1892 – page 67 – Monsell, Mitchell & Co, Timber, Slate, Stone, Tile, and Cement Merchants, 73, Townsend Street, Dublin. They are agents for Messrs. J. & M.

Craig, of Kilmarnock, Scotland, one of the largest manufacturing firms of fire-clay goods and sanitary ware of the very best description in the United Kingdom, comprising white enamelled bricks, scullery sinks, baths, lavatory basins, terra-cotta vases, pedestals, facing bricks, chimney cans, Buchan’s patent and Pott’s patent ventilating traps, special glazed sewer pipes and connections, etc., etc.

1893 – Advert J & M Craig.

1893 – 1896 – James Craig – Fire Clay Manufacturer and Coal Master. Deanmont, Kilmarnock.

24/07/1894 – Glasgow Herald – Scottish coal strikes …Messrs J & M Craig’s fire clay works at Perceton have been in operation up till the present time but the stock of coal there is now nearly exhausted and the works will probably be temporarily closed at the end of the current week …

05/10/1894 – Dundee Advertiser – Threatened closure of a pit – A notice is posted at the Perceton Pit, Irvine which is wrought by Messrs Craig of Kilmarnock Fireclay Works, that if the men don’t return to work at once the pit will be closed and contracts entered into with Lanarkshire coalmasters for supply of coal sufficient to restart the fireclay works.

Below – 1896 – J & M Craig advert.

1896 – J & M Craig were incorporated – J & M Craig Limited.

Below – 1896 – 1897 – J & M Craig Advert.

1901 – Directory of Clay Workers – J & M Craig Limited. Hillhead & Perceton Fire Clay Works & Longpark Pottery, Kilmarnock. Glazed wall tiles, white glazed fire clay sinks, wash tubs and supports, Craig’s ‘Million’ closets and urinal ranges, enamelled bricks and every description of fire clay goods and sanitary earthenware. London agents: Glazed wall tiles – R. L. Huxtable, 10 Arthur Street West, London Bridge, E.C.; Fire clay sinks and closets, Wm. Harriman & Co Ltd, 15 Charterhouse Street, Holborn Circus, E. C.; Sanitary Earthenware – G. A. Cowieson, 5 Charterhouse Street, Holborn Circus, E. C.

Below – 29/08/1901 – The Sanitary Press and Journal Vol 28 … The spigot and faucet drain pipes are made by machinery, the clay being forced through a “die” by means of revolving knives arranged inside a cylinder, something after the manner of the fan of a steamer.

The cattle troughs, horse mangers, etc., and the Buchan’s patent ventilating drain traps (of which Messrs. J. and M. Craig are the sole makers) are made in moulds. Those used for the drain traps are each in two halves upon which are laid webs of clay. When these have been beaten in with pads and have thoroughly assumed the shape of the moulds, the two halves are brought together, the joint is perfected by kneading, and the whole trap very carefully finished or smoothed over inside and out.

The pipes, traps, and other fire-clay sanitary ware manufactured by this firm are generally acknowledged to be the best in the market. They are made true to form, strong enough to resist all probable strain or pressure, and thoroughly glazed internally and externally so as to be impervious alike to liquid sewage and to deleterious and unsavoury gases.

Besides the articles mentioned, furnace blocks, gas retorts, chimney cans, flower vases, and every description of fire clay ware are produced at these works. Having the advantages of clay of unrivalled quality, skilled workmen, and long experience in the trade, Messrs. Craig have been enabled to furnish goods of such superior quality that they have gained the deserved reputation of being (as already mentioned) the foremost fire clay manufacturers in Scotland.

They have been awarded many prize medals in silver and bronze at Edinburgh, Glasgow, Dublin, and Ayr; and have also received first-class awards from the Sanitary Institute of Great Britain, and the Glasgow Philosophical Society, and at the London International Medical and Sanitary Exhibition. At the International Health Exhibition, they received three medals – gold, silver, and bronze.

Bricks and other goods manufactured by Messrs. Craig are exported to Canada, the United States, India, China, Australia, New Zealand, and other countries. Their gas retorts and fire bricks have been largely used in the Royal Arsenal at Woolwich, and their Buchan’s patent drain traps are in use at Balmoral Castle and in innumerable castles, mansions, public buildings, and private dwellings over all the kingdom.

About eighteen months ago a Pottery, for the manufacture of sanitary ware, was added to the other works …

1903 – J & M Craig Limited – Hillhead & Perceton Fire Clay Works & Longpark Pottery, Kilmarnock

Below – 1905 – 1906 – J and M Craig, Hillhead, Perceton and Longpark, Kilmarnock

1907 – J & M Craig Limited, Enamelled brick manufacturers, 105 & 98 Commerce Street, Glasgow.

21/12/1907 – Hamilton Herald – Auction sales. On an early day. At Perceton Collieries and Fireclay Works, Dreghorn. Colliery and brickworks plant, branch railway etc.

Below – 19/01/1910 – Derry Journal – Alex McElwee discharging a cargo of fireclay goods from the Crusader – J & M Craig, Kilmarnock.

24/12/1910 – Dundee Courier – New Scottish Company – Scottish Silica Company, Perceton Fire Brick Works, Ayr (Private Company). To carry on the business as brick makers etc. Capital £7000 in £1 shares. (Note – SBH – Is this the same as the Scottish Silicate Brick Company Limited?).

21/03/1913 – New Scottish Company – Perceton Silica Brick and Cement Company Limited, Perceton by Irvine (Private company) to carry on the business of brick manufacturers and tile and terracotta makers &c. Capital £2000 in £1 shares.

Below – 30/01/1915 – Donegal Independent – Robert Keys & Co – Sole agents in Londonderry for J & M Craig, Kilmarnock. (also 12/08/1910).

1918 – Shanks & Co acquired the earthenware manufacturers J & M Craig, Kilmarnock.

Below – 30/03/1918 – Hamilton Advertiser – Hillhead Fireclay Works, Kilmarnock for sale.

Below – 09/1931 – The Royal Engineers Journal – The demolition of a brickworks by Lieut-Colonel G. G McLean, R E (T). A very interesting article regarding the demolition of the Perceton Brickworks by 241 st Field Company.

.

Below – 1938 – Perceton Fire Clay Works, Perceton, Ayrshire.

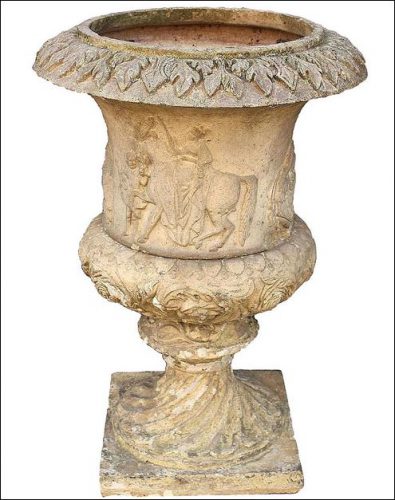

Below – 2015 – sold at auction – Large Scottish Fireclay Warwick vase and stand by J & M Craig, Kilmarnock. Mid 19th century – the low campana form urn with entwined branch handles and moulded with relief masks, on a squared plinth base moulded with rams’ masks, seraphim, and relief profile portraits of Robert Burns. 100cm wide, 114cm high.

Below – A Scottish terracotta bust of Robert Burns (1759-1796) by J & M Craig, Kilmarnock. Late 19th century. Stamped ‘J & M Craig/Perceton/Kilmarnock’ to the waisted socle, with residual painted decoration 40 in. (102 cm.) high. Source

Below – Pair of terracotta urns 23 1/2 in. tall, each impressed J & M Craig Ltd. Christie’s lot #440, $9,048.93. Estimate: $ 1000.00 – $ 2000.00 Sold at $4000.

Below – Scottish two-piece terracotta garden urn featuring a figural relief design, ivy leaves around the rim, a king astride a horse with attending knave, a man with griffin above clusters of roses, and rising on a swirl support and square base. Impressed mark on base: J & M Craig, Perceton, Kilmarnock – source

Below – c. 1900 – Front cover of a J & M Craig Sanitary Fire Clay Ware catalogue.

Below – 19/06/2016 – Some photographs taken at the old Perceton Fire Clay Works site and showing a substantial stone support for some unidentified heavy machinery and the boundary wall to the site which has been built with loosely laid in bricks or various shapes and sizes manufactured on-site.

.

.

.

.

.

.

.

.

.

.

.

Below – Some additional photographs of an underground tunnel or hot gas flue built with J & M Craig fire bricks. It does not appear to have been affected by heat so it may simply be for bringing water to or from the site?

.

.

Below – Two lovely examples of the J & M Craig stamps. The first is a brick built into the wall of the elaborate public conveniences in Rothesay, Bute.

Once ashore, the first building passed by passengers leaving the ferry from Wemyss Bay is Rothesay’s famous public convenience, built on the Pierhead in 1899-1900 when the resort was at its peak of popularity with day-trippers from Glasgow (Fig 330). This gentlemen’s lavatory was designed by the Rothesay architect John Russell Thomson (1841-1910), and the brown glazed bricks of its exterior were supplied by James Craig & Co of Kilmarnock; one of the bricks bears the firm’s name. Inside, the walls are lined with tiles, mainly yellow with some green, and on the ceramic mosaic floor, which includes the town’s coat of arms, stand twenty Twyfords imitation marble ceramic urinal stalls, six of them on a central island. The marble effect was achieved by the use of transfer printing. After being out of use for several years, the gents was restored and improved (a modern ladies toilet was created using outbuildings) during the early 1990s by Strathclyde Building Preservation Trust and the Jackfield Conservation Studio at a cost of almost £300,000; it reopened in 1994.

.

Below – Salt glazed drain plus grill photographed at Floors Castle, Kelso, Scottish Borders. J & M Craig and Buchan’s Patent.

.

.

.

Below – Many thanks to Ed Bral for sending this photo of an iron inspection cover for a water or sewer pipe – J & M Craig Limited Kilmarnock Buchan’s Patent.

.

****************************************

This is possibly James Craig of J & M Craig but I cannot confirm the same as yet. Can anyone confirm or otherwise. – click me

.

.

.

.

.

.

.

.

.

.