Southhook Fireclay Works, Dreghorn, Kilmarnock, East Ayrshire, later known as Southhook Potteries Ltd.

See also

Bonnyton Fire Clay Works, Kilmarnock, East Ayrshire.

See also

Shawsrigg Fireclay and Enamelling Company, Larkhall, North Lanarkshire

Canmore

Canmore

Canmore

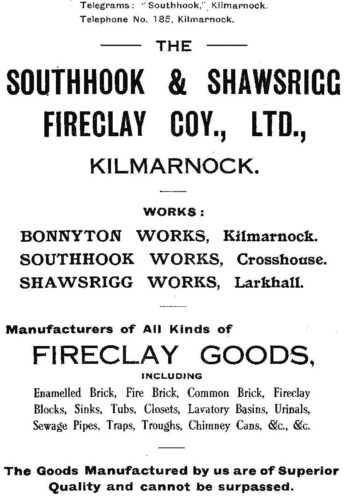

Southhook Fireclay Works – Dreghorn – The works was on the site of Southhook Colliery No. 1 Pit, which provided the fireclay. Slater’s Directory states that John McKnight & Co. owned the works form 1889 to 1893, but by 1904 the works had been incorporated as the Southhook Fireclay Company Ltd. Firebricks, glazed sewage pipes, and conduits for electrical cables formed the main products initially. In the 1930s the name changed to Southhook Potteries Ltd., and the company bought Bonnyton Fireclay Works which nearly doubled their capacity. Bonnyton had started prior to 1882 when it was owned by John Gilmour & Co., who had managed the Hillhead Fireclay Works before selling it to J. & M. Craig in 1867. The owners had become Gilmour, Morton & Co. by 1893 up to the 1914 war. Bonnyton Works was closed in the early 1970s and the site was cleared by 1973.

Among the many other smaller brickworks and mines in Ayrshire, the following produced fireclay or bauxitic clays, and most made some firebricks or refractory products such as chimney cans, and baby bricks for domestic fireplaces and stoves. Source Kenneth W Sanderson

**********************************************

Industrial and private rail lines. Ayrshire County pages contain details of Industrial and other Private lines that do not form part of any of the principally listed companies on this website

Southhook Colliery & Fireclay Works, Crosshouse – Southhook and Shawsrigg Fireclay Co until 1913; then Southhook Potteries Ltd. Closed 1924.

Bonnyton Colliery & Fireclay Works, Kilmarnock – Southhook and Shawsrigg Fireclay Co until 1913; then Bonnyton Potteries Ltd until 1935; then Southhook Potteries Ltd. The colliery closed in 1913, fireclay works closed in 1923

Bourtreehill Colliery & Fireclay Works, Dreghorn – Southhook Potteries Ltd. The colliery closed in 1924, fireclay works much later.

Source

***********************************************

Southhook Pit, one of the oldest clay pits in southwest Scotland is situated near Knockintiber, just outside Kilmarnock. Now closed down, it once belonged to Southhook potteries, Ltd., one of the countries foremost manufacturers of sanitary ware and bricks. The first recorded use of the site was in 1877 but it is probable that ironstone was worked there earlier. The clay was peculiarly free from impurities and was specially adapted for the manufacturing of large pieces such as baths, urinals and sinks. The glazes were highly lustrous and guaranteed to be leadless and non-crazing. The pottery’s Bonnyton works in Kilmarnock were where they manufactured most of their products including their salt-glazed drainage pipes. In 1963 Shanks acquired Southhook Potteries, and then 2 years later in 1965 Shanks & Co. also acquired J&R Howie from Hurlford, and traded under the name of Howie Southhook. Shanks Holdings Limited merged with Armitage Ware Limited in 1969 to form Armitage Shanks.

09/08/1901 – Ardrossan and Saltcoats Herald – Mr James Anderson Coalmaster, Craiglea, Troon, is one of the signatories to the Southhook Fireclay Company Limited which has just been registered. The capital is £10, 500 in £1 shares which have all been subscribed privately. The company has been formed to adopt an agreement with Anderson & Gilmour, coalmasters and brick manufacturers, Southhook, near Kilmarnock and to carry on the business.

31/10/1903 – Maryport Advertiser – New inventions. Weekly reports by Messrs Cruickshanks and Fairweather, chartered patent agents, 62 St Vincent Street, Glasgow. The following specifications of patents were accepted by the controller general during the preceding week … Southhook Fire Clay Company Limited manufacture of glazed bricks …

Below – 1908 – Map of Southhook Fireclay Works.

1908 – 1909 – Southhook Fire Clay Coy., Ltd., manufacturers of white and coloured enamelled bricks, vitrified facing and fire bricks; also, white enamelled sinks, washtubs, closets, urinals, and other sanitary goods; Glasgow office, 98 Commerce st., and depot, Cook Street Terminus; Nat. Tel., 1791 south side. P.O. X 98; works, Crosshouse, Kilmarnock; Nat. Tel., 56 Kilmarnock; Tel. addresses, “Japstane” Glasgow and ” Southhook ” Kilmarnock.

04/08/1909 – Belfast Telegraph – Big Glasgow fire. Damage to the extent of £1,000 was done by an outbreak fire which occurred at an early hour this morning in a large four-story building at the corner of Commerce Street and Wallace Street, Glasgow, occupied by the following firms; Messrs. Elkington & Co., silversmiths and electro-platers; Messrs. Thomas Smith & Sons, also silversmiths; Messrs. A. Cairns &. Co., rubber manufacturers; Messrs. C. D. Whitelaw, Limited, coopers; the Glasgow Cycle Company, the Southhook Fireclay Company, and Messrs. Murray & Stewart, lime and cement merchants. The fire originated on the ground floor and had got a good hold before it was detected. It seemed as if the whole building would be involved, but the firemen managed to prevent the flames from spreading to the silversmith’s establishment, which is situated on the top floor and ultimately extinguished the outbreak.

Below – 12/04/1910 – The Edinburgh Gazette – Southhook Fireclay Company buys out the Shawsrigg Enamelling Company and they continue to trade as Southhook Fireclay Company Ltd until at least 1921. ( K. W Sanderson).

19/04/1913 – The Scotsman – The Southhook Fireclay Co are putting down a bore near to Warrickhill old mansion house (Ayrshire) to prove the minerals there.

05/06/1914 – Kilmarnock Herald and North Ayrshire Gazette – Death of Mr James Anderson. We regret to announce the death of Mr James Anderson, fireclay manufacturer of Southhook Fire Clay Co Ltd which took place at his residence at Parkstone, Prestwick. Deceased was a son of the late Mr Gavin Anderson, coalmaster, London Road and a nephew of the late Mr Blair of John Walker and Sons Ltd, Dundonald Road …

Below –22/10/1914 – The Scotsman – Court case – Contract for bricks due for export to Canada. Appeal – Southhook and Shawsrigg Fireclay Co Ltd V Thomas Bell Sons and Co.

30/03/1918 – Hamilton Advertiser – For sale … Messrs Southhook and Shawsrigg Fireclay Co Ltd, Kilmarnock. A trestle pithead frame about 35ft high. Nearly new.

23/06/1920 – Coatbridge Express – History of Dundyvan Brickworks. The employees of the Eglington Silica Brick Company Limited at Dundyvan Brickworks had their annual trip to Lanark on 5th June and a goodly company enjoyed the outing in the ancient burgh. Mr Wm. Donald, general manager, was present and at the conclusion of dinner, he made interesting reference to the history of their works.

Many trades, he said, that put out enormous efforts for the country during the war have had to pause and look around now that the war is over but with us it is different. Our trade is to supply the requirements of the steel trade and if the steel trade is busy, we shall be busy. Our duty is to see that the steel trade is never short of supplies of magnesite bricks. Another of our duties is to see that they get plenty of ground magnesite. And, as soon as we can, we should make them some chrome bricks, but we can’t do that while we are busy on magnesite bricks. When we do all we can, we are doing our bit. That is why you are all so busy, and you can understand from what I have said that we could have plenty to do for a long time ahead.

If we do all we can to keep the quality up to our highest level we will always have plenty to do, and something to spare for others in the trade. It doesn’t do to be the only arm in the trade. I find the other members real good friends, we have an Association – The magnesite Brickmakers’ Association – so that in addition to being members of your own Societies you are members of the Magnesite Brickmakers’ Society. Some of you will know, and others I think will be interested to know, that in 1871 there was another war in Europe. At that time it was Germany and France who were fighting over Alsace and Lorraine. Some of you know Alsace, where Metz is, opposite and near to Verdun, and others will know Lorraine where Strasbourg is. Germany won and occupied Paris, and France had to pay up. Now the tables have been turned and France has got back the Alsace and Lorraine countries taken from her.

Now, it was soon after and as a result of that Franco-German war that the Eglinton business first began. Land was got at Irvine harbour, and works were started to make chemicals that were in great demand. Limestone wait required, and the best stone was in County Antrim, but they couldn’t get enough, so my father went over to Ireland and out the Glenarm Quarries from Lord Antrim, built a pier, and built two steamers and got his limestone that way. In that limestone there were beds of flints and flints were bad for the chemical works, so that had to be removed from the limestone and soon a good many thousand tons of flints accumulated and had either be made into something or cleared out of the way. Well, as a result of that war steel was required, and the Blochairn and Hallside Steel Works were erected in Scotland and required silica bricks. My father knew that silica bricks were being made from flints on the Thames or were trying to be made, and be decided to make them on the Clyde. At that time Roberts had a foundry in South Wales where he made castings for brick machines like what we used to use. After giving his price for brick machines he offered to supply mills and to build stoves and kilns and the result was that he gave up his business in South Wales and came to Scotland with Norman and Jim Hannaford, who is now the foreman at Braehead. Roberts became the first works manager at Dundyvan, and the stoves and kilns were built by Mr Jamieson, the builder, to the plans that Roberts brought with him from South Wales. So that Dundyvan with all these Welshmen began as a colony of South Wales -a little New South Wales. That was in 1889. There have been ups and downs since then. At first, the steel trade of the Clyde was most affected with the Clyde shipbuilding. When therefore shipbuilding was busy, so was Dundyvan. After Roberts, the manager was Norman, then McGregor, the man with the one arm and then Dan Fraser. Fraser left in 1909 and it was that summer I came among you and became the works manager for six years. You will remember that my father was run over in January 1915. At that time I was far from well and he was Dundyvan every day. One morning he came down early and came in at the No. 3 gate. The pugmen didn’t see him, and the pug came round the corner too quickly and my poor father couldn’t get past quick enough. A good many of you will remember my father and his great interest in all stages of manufacture. Sometimes he was too particular. But he was an exceedingly goodhearted master, and to all who knew him well, a good friend. He had a wide circle of friends. His death made it necessary for me to take up the reins, and I wasn’t long in seeing that with the altered circumstances of the war, calcined magnesite couldn’t be got. We would have to take cargoes of raw magnesite. Now the Dundyvan kilns at that time weren’t enough to do much calcining, burning of slap bricks and burning of finished, and 1 made up my mind that, I had to get hold of another Works. At first, I thought of Braehead but I soon saw that wouldn’t do what would be required without more plant first being erected at Dundyvan, so I leased Garnqueen, with the expectation that the kilns there would at least be able to do the calcining. The cost of upkeep of these kilns working at our high temperatures was very great for the work they did and the quality of the calcined magnesite produced was not nearly so good as what can be done at Dundyvan.

Relating the work done during the war Mr Donald said – By October 1916, we had become the largest makers in this country. In October that year, the steel trade wasn’t getting enough. So all the makers were called to the Ministry of Munitions and we were all asked what we could do. I promised to increase our production by a quarter within three months and I was asked to do it When that was done I was told one day that bigger supplies would be required. Could I do anything more? Well, I knew myself from the orders I had to refuse that more was required and I had been making enquiries about other works I could get. So I promised to come back in a week and let them know what could be done. Well,, when I came to Scotland the likeliest works were Shawsrigg Works, Larkhall, and the calcining kilns at Armadale. So I went back in a week. I remember it was 4 o’clock, on a Saturday afternoon, and I offered to double the production within two months if that was wanted, provided I could get more magnesite and provided I got some Garnqueen man back from the Army. That was promised, so I went ahead, the kilns at Shawsrigg were muffle kilns. These muffles had to be cleared out. The old set of kilns had to have their crowns put right. A brick machine had to be got to Shawsrigg and erected there and the mills had to be thoroughly overhauled. The works had been idle for two years and workers had to be got. The railway siding plant had to be extended, and the water supply was bad. A new pump had to be got, and so on. Also, we had to get another machine for Garnqueen so that we could depend on one always being right. We had also to get a second lightning crusher. The first lightning crusher had been got from Braidwood. The first machine came from London. Another was got from Irvine. The next was got from Gloucester. The next was got from Hull. And the next was got from Dublin. It was only by getting them second-hand from where they existed, in works that were closed down, that the machinery could be got in time. Well, that gave us Dundyvan, Garnqueen, Shawsrigg and Armadale. At Armadale, all we did was calcining. Calcining was also done at Shawsrigg and Garnqueen, as well as slap bricks, and the first burning came to Dundyvan to be made into finished bricks. Later there wasn’t ever then enough, and we had to take the works at Kilmarnock. There was great excitement at that time. I had already entered into a contract to supply the French Government with three-quarters of a million magnesite bricks. Now Italy had joined the Allies and a representative from their Ministry of Munitions in Rome called at 45 Renfield Street and asked what we could do. I said quite simply that there was no limit to what we could de if we had enough magnesite and enough works to make bricks. So they asked me to supply a quarter of a million, delivering 50,000 in May, June, July, August and September in 1916. As soon as the arrangements were completed I went ahead at Southhook Works near Kilmarnock. One of the ‘Clan’ Line arrived from India. The raw magnesite was sent straight down there. Soon we began to get it into slap bricks and got them out too. So the production game began on a bigger scale. Well, we were up to time with the increased production. A wire came from the Ministry saying they had a wire from Italy wanting the bricks. Where were they? So I replied they were still in the kiln but the kiln door was down the previous day and we could have them packed up and despatched that week. That was how the thing went on and by September 1916 we had delivered the 750,000 to France and the bricks to Italy as well. That having been done the question was – What next? Well, the usual course of business is to execute orders but during the war, more questions than that had to be taken into account. The Germans settled this particular question for us. They sank two steamers with magnesite and made such havoc with their submarines that it was decided to restrict all exports and only to import magnesite to meet the demands of the British works. These were going to be very great, and it would be difficult to get all the supplies of magnesite from Greece that would be required.

It was decided, therefore, that Southhook and Shawsrigg Works and the Armadale Kilns would be given up and we would work away with Dundyvan and Garnqueen. In the meantime, Dundyvan had grown. We had kilns 9, 10 and 11, and at Garnqueen we had built eight Newcastle kilns. At Dundyvan also we had added stoves 5 and 6. Since the Armistice, we had the sale at Garnqueen of all the spare machinery and since then we have gone ahead at Dundyvan setting our house in order. That is what the steelworks themselves had been doing, and soon their orders came along again. This time with increasing orders. I made up my mind that to get the extra plant to give the increased production I wouldn’t go back to fireclay works, but would erect the most modern plant at Dundyvan, taking the erections decided on in their order of most importance. When we get erected all that has been purchased we shall have the best magnesite works in Great Britain.

There is a good old saying that “All work and no play makes Jack a dull boy”. More than that, however, it makes him less able to concentrate his attention to matters that his competitors pay attention to. All workers in any branch of trade have competitors in that same branch of trade either in the adjoining street, town, county or country, and it is just as necessary for each worker to consider his work in that light as it is for the employers to think how they can compete with other employers by the introduction of better machinery and plant. Employers depend on the machinery and plant being worked with the highest skill, and with the greatest economy. It is up to the workers to back up the employers and each to compete, with the workers who are doing the same job in the towns or in other countries. On the other hand, it is up to the employer to consider whether they can assist the workers by giving good working conditions, light and fresh air, protection from bad weather and warmth whenever necessary. In country districts, it is often necessary to provide travelling facilities and housing accommodation. In towns like Coatbridge, where the workers have the choosing of the town councillors just as much and even to a greater extent than the employers have, they can introduce in their towns good education, good lighting, good tramway travelling facilities, good drainage, and in these days of town planning they can also introduce good housing schemes. In works that are situated in burghs or towns, the employer has taxes to bear that lighten the burden of the residential inhabitants and the workers, so that the inhabitants are all the better able to have the best conditions of life in their midst. It is mainly in their works themselves that the employers have their responsibilities, but my opinion is that it would be good for all employers if they gave their workers ground for development in allotments so that their interests in many of the things they have learned in their youth in country districts can be sustained. It is my hope that soon will be able to provide our workers not only with improvements in the working conditions at Dundyvan in many respects but also that at no distant date we shall have a field, part of which can be used as a football field either by the younger workers themselves or by the children of the older workers and in part of which the workers will have allotments that they can cultivate for the growth of vegetables and flowers. You will see from the coloured print of the Veitsch Company’s Works and buildings that they have a bandstand and laid out gardens for their employees. If they had not deployed their works first they would not have gone in for such wonderfully good developments in these directions. But their enterpriser before the war was really wonderful, and their spirit I hope to develop at our works in Coatbridge. The Veitsch Company are far away among the Austrian Alps. A panoramic view of these is exhibited. The works are five or six miles from any railroad and all their bricks and bags of magnesite have to be carted through a narrow valley to the Murs Valley where the lines run either east or west, either to Trieste, which is shown on the map, where shipments take place or towards Vienna where the railway lines distribute the goods to the various consuming centres. Shipments at Trieste are very difficult just now. Steamers take a long time to load. There are very few locomotives in the country. Such as there are, are using wood logs as fuel. You can imagine how much steam we could keep on our main boiler if we had only wood to burn. You can imagine how many carriages could have come from Coatbridge to Lanark today if the engine had logs of wood to burn instead of coal. I met a man recently, the representative of a very large Paris and London firm, who told me his principal was travelling from one end of Austria to the other, and also in Germany and that it was an ordinary occurrence for trains to stop between stations and for any timber near at hand, either fences or gates, or even parts of the carriages them, selves to be collected by the passengers so as to provide enough wood to steam the engine to the next station. My brother law is in that part of the world just now, and he tells me that the trains travel with only one-third of the usual carriages and that even though you have been travelling for two days and two nights in succession and are tired out, you can’t sleep in the trains for the shaking, and the jolting.

While they have plenty of food in the country districts, the food in the cities sells at ransom prices. They have no transport facilities. Coal costs anything from £15 to £20 per ton. You can imagine, therefore, with no coal supplies how many kilns they can with logs of timber, and how many tons of dead burned magnesite and magnesite bricks they can supply. Of course, their competition is bound to come later, and it is for that reason that we are doing all that we can overtake to get erected a good milling plant and good calcining plant so that we can do at our works all that they can do at theirs. When our plant is erected it will be up to the workers to work the plant with the highest skill. You will compete with the labour of the Continent to do the work to the highest standard and as economically as possible. Wages will not come down until the cost of living is greatly reduced, but all workers should consider whether they cannot give a little more production. That may only be possible if the machinery or plant is altered so as to suit better the labour being done. The intention with us will be to give any proposal that is put forward by any of the workers in that way every consideration possible. Now, there is no use of speaking in generalities without giving an application to those general ideas, and I would like to refer in a few words to two matters that I know have been very much on the mind of our works manager. One of these has to do with the percentage of rejected magnesite bricks and the other has to do with fuel consumption.

I think the workers are to be congratulated on their having fixed an annual dance as you did last winter and also on the annual trip which you are beginning today. Whoever it was who originated the idea deserves credit. I shouldn’t be surprised if it was Maggie Toal and if it was, her name should be remembered and go down to posterity in the history of the works. I am more glad still that you are having such a fine day. I think the committee acted wisely in having a set dinner and afternoon tea, as they have done, and also in deciding that for this year they would have drives rather than sports. Perhaps for next year, now that the minds of the workers have become accustomed to the idea of an annual trip they will set themselves to begin to lay up for six months ahead of the trip, and if so they will be able to go further afield, either by train or by motor transport. There is nothing like providing well beforehand, and perhaps you will let me provide you with an idea about next year’s trip. That is, that it should be a trip either to the head of Loch Lomond or to Dunoon so that you could have a complete change of air and a good dose of sea breezes. I think you have been fortunate in choosing Lanark this year so that you can all get to know the county town of our county of Lanarkshire and to know the Falls of Clyde in the neighbourhood. This is one of the oldest burghs in Scotland. It was a place of residence of the Scottish kings before the English invasion of the times of Wallace and Bruce. Some of you may have been at Stirling and know the William monument. You can also see a statue of Wallace before the church steeple in the square. Wallace was one of the greatest men of Scottish history and though he wasn’t born here (he was born at Elderslie near Paisley) his young wife, Marion Bradfoote came from Lanark and it was at Lanark he first became prominent and famous. That’s a long time ago, seven hundred years ago and more, but it is undoubtedly due to his tremendous energy that the Scottish people retained their self-esteem and strength of character during a series of most trying experiences – The Scots came out well. I think it is a somewhat similar experience on much vaster lines that the whole people of this country of ours are emerging from. The recent war was a tremendous experience for all of us while it lasted. But I believe that we have all gained in strength of character and the best way to show that is in the work that we each of us do. Mr Lawson Scott, works manager thanked Mr Donald for his presence and interesting statement.

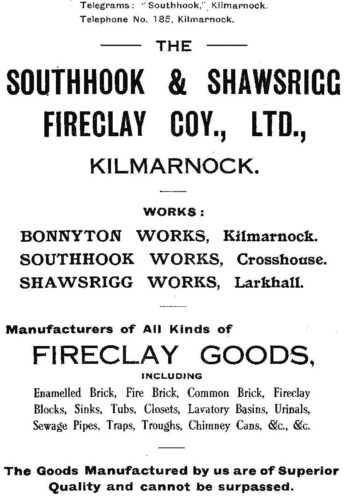

Below – 1923 – Kilmarnock trade directory – Southhook and Shawsrigg Fireclay Co Ltd, Kilmarnock. Works, Bonnyton, Southhook and Shawsrigg.

25/03/1929 – Published in the Scottish Pottery Society Bulletin no 37, November 2003. The Scottish Enamelled Brick Co., Ltd letterhead. The letter is written to a customer to accompany a copy of their ‘Brick Pattern Book’. The letterhead also details the fact that the company works are situated at Ferguslie, Paisley; Plann, Crosshouse and Southhook, Crosshouse. (Many thanks to George Haggarty for this information).

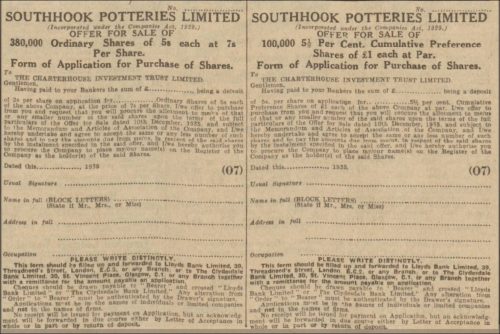

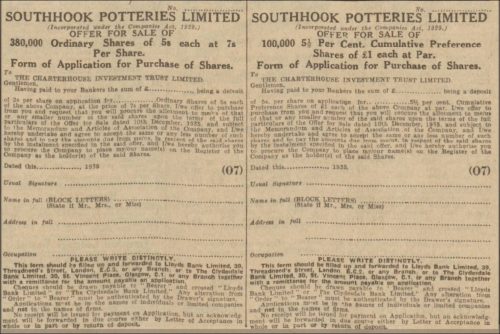

Below – 12/12/1935 – Dundee Courier – Southhook Potteries Limited – offer of sale – shares.

Below – 12/12/1935 – Dundee Courier – Company history. The Company which was incorporated as a private company in November 1935, under the title Bonnyton Potteries Limited, was converted into a public company on 2nd December 1935 and has agreed to acquire from the Kilmarnock Trust Limited (now voluntary liquidation) as of 31st July 1936, the business hitherto carried on under the name of Southhook Potteries Limited, excluding an unremunerative section of the business known as Shawsrigg Works. In addition, the Company has agreed to acquire outright my interests in certain Patents which have hitherto been operated by the Vendor Company on a profit-sharing basis. The business was founded in 1901, and a reputation for quality and service has been built up amongst its customers for fireclay sanitary ware of all descriptions, glazed blocks and tiles, sewage pipes, fire bricks, facing bricks and building bricks. The main Fireclay Works known as the Bonnyton Works are situated at Kilmarnock, and the Company also owns at Southhook, some 2 1/2 miles distant, a lease of the property from which its raw materials are obtained. This property is directly connected with Bonnyton Works by railway, and the available supplies of clay are estimated sufficient to meet the Company’s requirements for over thirty years. At Southhook the Company also has works suitably equipped for the manufacture of fire bricks and building bricks. The productive capacity of the business has been steadily increasing during the past few years and the Company now owns one of the most modern and efficient fire clay works in the United Kingdom. The first rotary gas-fired kiln to be installed in this county was erected at Bonnyton Works in 1925, and after an experimental period proved so successful that a second kiln was installed in 1930. At these works, there are also a number of Newcastle muffle kilns, which are in first-class condition. The Company’s products are supplied to Government Departments and to numerous private undertakings and public authorities at home and abroad. An extensive and increasing business in certain lines which the Company specialises in is expected to accrue from Municipal and other Housing Schemes which are now in progress or under consideration.

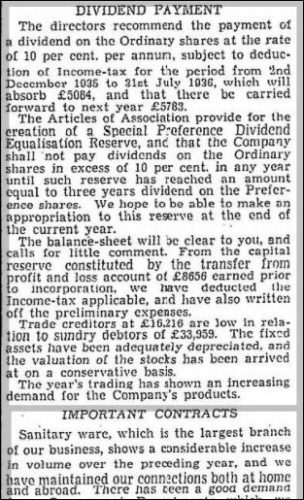

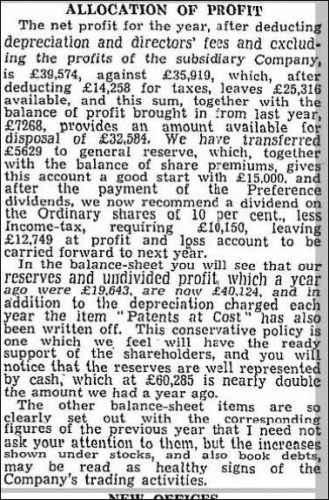

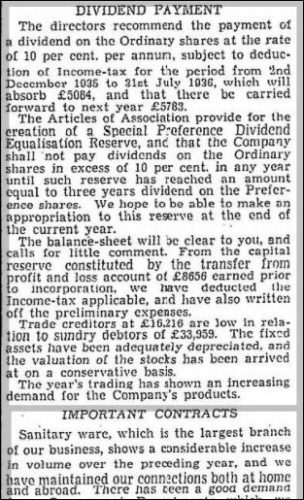

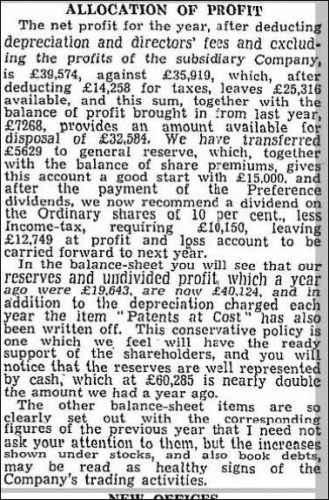

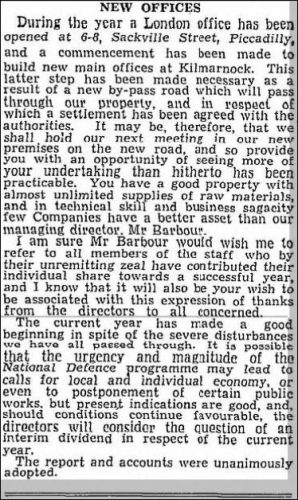

Below – 27/10/1936 – The Scotsman – Southhook Potteries Limited discuss trade and prospects.

.

.

05/10/1937 – The Scotsman – Southhook Potteries Company which has its headquarters at Kilmarnock has acquired the whole of the issued share capital of the Bourtreehill Coal Co Ltd which has a connection in the fireclay and sanitary ware trade.

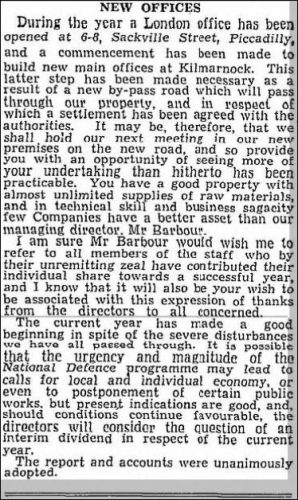

Below – 26/10/1938 – The Scotsman – Southhook Potteries Limited company update.

.

.

.

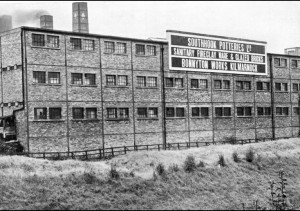

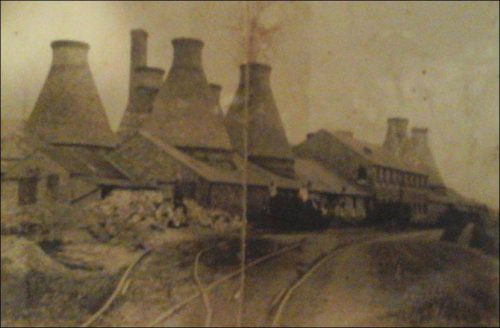

Below – 1938 – Southhook Fireclay Works.

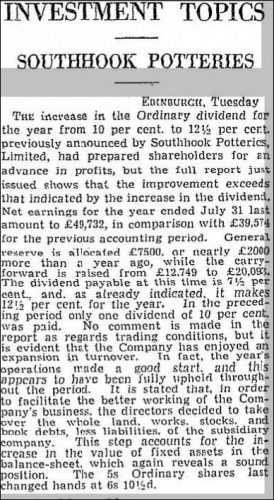

Below – 18/10/1939 – The Scotsman – Southhook Potteries Limited company update.

26/07/1940 – Kilmarnock Herald – Fatal accident at Southhook Potteries. A middle-aged man died in Kilmarnock Infirmary last Saturday morning in consequence of injuries received at his employment at Southhook Potteries, Kilmarnock, on the forenoon of the preceding day. It is believed that the unfortunate man, John Taylor, Cameron’s Buildings, The Cross, Crosshouse, was endeavouring to make secure one of the running belts when the machine was turned on and he went tumbling into what is known as the “mixing pan” at the works. The victim was cautiously carried from the scene of the accident to a waiting motor vehicle and conveyed to Kilmarnock Infirmary, suffering from terrible injuries to his arms and body, and from severe shock. His injuries were of such a serious nature that he succumbed within fourteen hours.

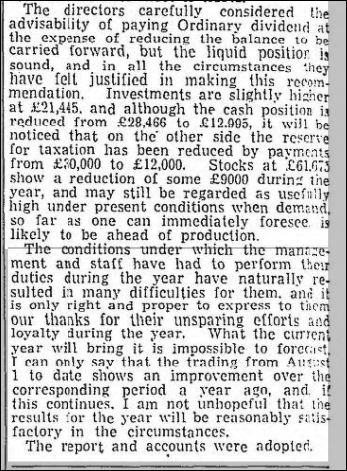

Below – 30/10/1940 – The Scotsman – Southhook Potteries Limited company update.

.

.

Below – 09/12/1942 – The Scotsman – Southhook Potteries Limited company update.

.

Below – 03/11/1943 – The Scotsman – Southhook Potteries Limited company update. Mr H. A Holmes, Chairman reports.

Below – 1944 – 1967 – Southhook Fireclay Works.

Below – 1944 – 1967 – Possible clay mine for Southhook Fireclay Works. It is situated just a few hundred yards from the Works.

Below – 07/10/1944 – The Scotsman.

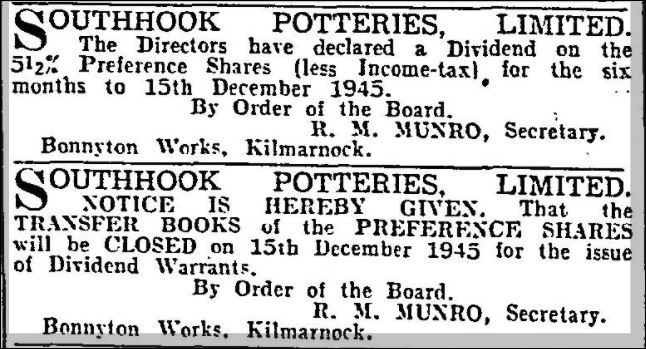

Below – 19/11/1945 – The Scotsman.

1946 – 12/10/1979 – Kilmarnock Standard – … Bonnyton community centre wasn’t purpose-built. It was formerly offices for Southhook Brickworks and became a community centre in 1946.

Below – 02/06/1947 – The Scotsman.

06/02/1948 – Kilmarnock Herald – Fatal accident enquiries … At the same court, a verdict of death from carbon monoxide poisoning and severe burning was returned on John Miller, who resided at 9 Altonhill Avenue, Kilmarnock. The jury added a verdict through misadventure. The dead man was engaged at Southhook Potteries on new year’s day when his duties were to feed the gas producer with coke. He was missed and a search had located him lying on the floor of the building, dead and with severe burns, some of which were received before he died.

24/01/1950 – The Scotsman – Pottery worker’s health … Members of the British Stoneware Manufacturers Association include A. W. Buchan & Co, Ltd, Portobello, and Govancroft Pottery Co Ltd, Tollcross, Glasgow. The National Federation of Clay Industries membership includes Chas. Buick & Sons, Ltd, Alloa; Shanks & Co, Ltd, Barrhead: Steele Bros & Sons. Ltd, Edinburgh; John Steele & Sons Ltd, Glasgow and the following Kilmarnock firms: Bourtreehill Coal Co, Ltd; J. & R . Howie, Ltd and Southhook Potteries Limited.

17/03/1950 – Kilmarnock Herald – Court case regarding John Fulton, brickworker of Busbie Cottages, Crosshouse being charged with the theft of steam tubing from Hayside Colliery occupied by Southhook Potteries Ltd … Hayside colliery was now only used as a main pumping station for Southhook Potteries …

22/01/1952 – Yorkshire Post – Southhook Potteries Ltd, Kilmarnock, require an experienced representative living in Lancashire or Yorkshire to work the Midland Counties; applicants must own a car for which suitable allowance will be made; good salary and encouragement to a suitable man. Applicants to state age. experience, particulars connection, etc.. letter to Secretary

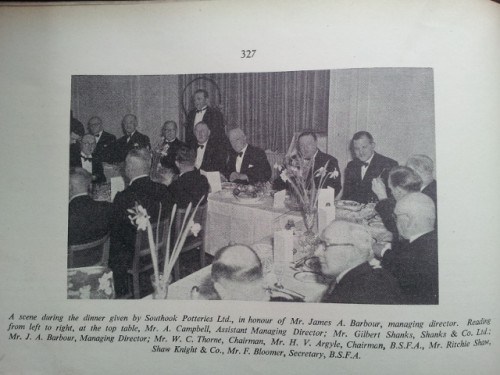

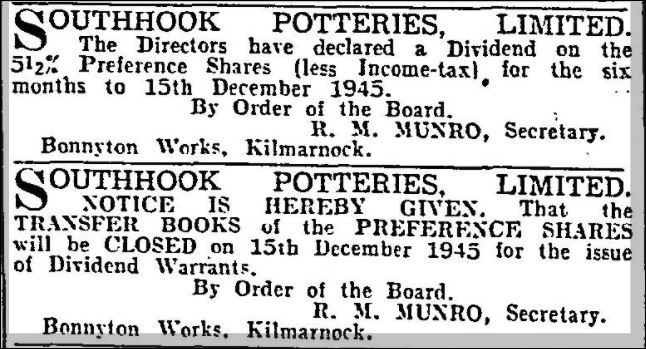

Below – 15/03/1952 – The British Clayworker – Presentation to Mr J. A. Barbour Southhook Potteries Function. Directors of Southhook Potteries Ltd., Kilmarnock, last month attended a complimentary dinner in the Airport Hotel, Prestwick, in honour of their managing director, Mr James A. Barbour a well-known figure in the trade. Mr Barbour has just completed forty-one years’ service with the Company, first of all as secretary, then as director and latterly as managing director, and last month’s function was arranged in order to present him with a gift to mark the occasion. Senior members of the Company’s staff and guests from other Fireclay companies were also present.

In presenting Mr Barbour with a console television set from the directors, Mr William C. Thorne, chairman of the Company, who presided at the function, recalled how Mr Barbour had joined Southhook in 1910. Four years later he had been appointed as secretary and in 1924 he was elected to the Board and established as managing director.

“Mr Barbour has always taken a keen interest and leadership in the activities of associations connected with the trade,” said Mr Thorne, “and this is borne out by the fact that some of those most influential lay connected therewith are here tonight as his friends. Mr Barbour reads and learns; he keeps his mind forever on his work and always puts his acquired knowledge to the test, Such experience and knowledge is, I should venture to say, second to none in the Fireclay trade.”

Mr Thorne went on to comment upon the many innovations and improvements made by Mr Barbour at Southhook during the past forty years, all of which had contributed in very large measure to making Southhook the great force it was today in the Fireclay trade. He referred in particular to the interest which Mr Barbour had always shown in Bourtreehill, the mine where the Company gets most of its clay and some of its coal. “Mr Barbour he said, “has always had a very keen interest in the mine which he recognised as the bloodstream of the Company, and development plans have been constantly exploring the possibility of the clay seams there. Today we are working clay seams which are reckoned enough for a hundred years.”

In closing, Mr Thorne referred appreciatively to the co-operation and assistance which he had received from Mr Barbour since he was appointed company chairman in 1944. “During these eight years,” he said, “I have come to appreciate the very high standard of knowledge expounded and put into practical use by Mr Barbour.”

Acknowledging the gift, Mr Barbour recalled how, very early in his career, he had coined the word “stickability” as his motto, “The word may be defined as the power of the individual to finish a job once commenced,” he said, “notwithstanding any difficulties encountered in the way.”

Proceeding, Mr Barbour recalled how, when he was engaged in the early development of Southhook, the gift of “stickability” had been a prominent feature of the many friends in works and office, who had assisted him in his heavy task.

“To mention any name at this moment would be invidious,” he remarked. “We have been a very happy team. It has required hard work from everyone but I do feel that the measure of success which has attended this hard work has to a large extent been ample compensation for the efforts which have been put forward. It is a happy thought that the Company has prospered and become an organisation which is respected in the trade and of which we have every reason to be proud.”

Mr A. Campbell, another director of the Company, welcomed the guests and added his own tribute to Mr Barbour. “It would be an unforgivable sin,” he said, “we’re into hesitate about adding my stone to the cairn of admiration and appreciation you, Mr Thorne, have raised to my colleague of forty years, Jimmy Barbour. We were young men when we first met at Bonnyton but from that day until now has been to me an example of industry and indomitable Scottish courage.”

Mr R. M. Munro, secretary of the Company, said that Mr Barbour’s failures were but the stepping stones to achievement. He had never depressed his colleagues when his experiments were not successful. On the contrary, he had immediately set himself to experiment further until he had attained his objective.

“This presentation is long overdue,” said Mr John Bruce, works manager. “No man is more entitled to the recognition the Board has conferred on him tonight.”

Other tributes to Mr Barbour were paid by Mr H. Preston, director, Mr M. Young, director, Mr M. Logan, engineer, Mr R. Shaw, Bishop Auckland, Mr Gilbert Shanks, Messrs, Shanks & Co. Ltd., Barrhead, Mr H. V. Argyle, chairman of the Fireclay Manufacturers Association, Mr F. Bloomer, secretary of the Association.

A vote of thanks at the close to the chairman was proposed by Mr J. Laird, director.

Above – A scene during the dinner given by Southhook Potteries Ltd., in honour of Mr James A. Barbour, managing director. Reading from left to right, at the top table, Mr A. Campbell, Assistant Managing Director; Mr Gilbert Shanks, Shanks & Co. Ltd.; Mr J. A. Barbour, Managing Director; Mr W. C. Thorne, Chairman, Mr H. V. Argyle, Chairman, B. S. F. A., Mr Ritchie Shaw, Shaw Knight & Co., Mr F. Bloomer, Secretary, B. S. F. A.

21/09/1954 – Yorkshire Post – Southhook Potteries announce that Mr James A. Barbour has resigned from the board.

1961 – 1962 – Directory of Clay Workers – Southhook Potteries Ltd, Bonnyton, Kilmarnock, Ayrshire. Tel Kilmarnock 1332 – 5. T Address – Southhook. Enamelled fireclay goods, glazed pipes, glazed bricks, fire bricks and building bricks.

18/05/1962 – Wishaw Press – Plumbers visit potteries. Members of the Lanarkshire District Council of the Registered Plumbers Association journeyed by car last Thursday to the works of Southhook Potteries Ltd., Kilmarnock. They were met by Mr J. H. Preston, director, and Mr G. Ritchie, Lanarkshire representative, of Southhook Potteries Ltd., along with several leading members of the staff who speedily divided the party into groups and sent them off on a tour of the works. Crude clay is put into a mill and mixed with “brock” to aerate it. It is afterwards dried and reduced to a powder state then mixed with specially treated water to form a ” slurry.” From the tanks containing this “slurry”, it is pumped to the moulding department ready for use in the moulding of tub and sink sets, basins, w.c.’s, cisterns, and especially grazed (glazed?) bricks etc. After these articles are dry they are removed from the moulds and allowed to harden. When ready, they are coated with several coats of vegetable paint before the final glazing preparation. They are then taken to a rotary kiln. This kiln takes 103 hours to complete the circuit and the articles in this gas-heated kiln are subjected to heat rising from normal temperature to a maximum of 1220 degrees Fahrenheit. When taken from this kiln they are thoroughly tested and examined before being removed to the stores department. After the tour, the party were entertained to tea and refreshments. Mr Prestonon behalf of the board of directors expressed pleasure at having the Lanarkshire plumbers as their guests and extended a very warm welcome for a return visit to their other works as and when they desired. Mr George Martin, president of the council thanked Mr Preston and the management for the privilege of the visitation. The arrangements for this visit were again in the capable hands of the Association’s secretary, Miss Cathie Hinshalwood.

08/03/1963 – The Glasgow Herald – Shanks take over offer – Shanks & Co., of Barrhead, the sanitary engineers and fireclay manufacturers, are offering to take over Southhook Potteries, of Kilmarnock, who are in the same line of business. The directors of both companies have agreed on the merger. Details of the terms of the offer to Southhook Potteries share-holders appear on page 4. Both companies originated last century. Shanks have two works at Barrhead and one at Kilmarnock. Their net profit for 1961 was £80,787 and an Ordinary dividend of 12 1/2 per cent was paid. Southhook’s net profit for the year to October 31, 1962, was only £797 and no Ordinary dividend was paid.

16/04/1963 – The Glasgow Herald – Shanks & Co Ltd – Difficult Conditions During Year – Prospects more favourable. The sixty-fourth Annual General Meeting of Shanks & Co., Ltd., will be held at the Company’s Head Office, Tubal Works, Barrhead, on May 8th.

The following statement by the Chairman, Mr G. M. Shanks, has been circulated with the Directors’ Report and Accounts for the year ended December 31, 1962:-

In my statement a year ago I spoke with reserve regarding our company’s immediate prospects. So many uncertainties lay ahead that it was impossible to predict what future trends would be. It is now apparent that I was fully justified in making no optimistic forecast. We have undoubtedly had difficult conditions to face during the year.

Although our turnover in the home sector, due to recovery in demand during the final months, has fully equalled that of last year, our shipments to our old established markets abroad have again fallen away. This has been due, as mentioned in my last statement, to the growth of local manufacture, intensification of import restrictions and unstable political conditions. While we have increased our trade with other countries, the volume of new business so gained has not been enough to offset the loss.

Our marine branch, due to the depression in the shipbuilding industry, has also had a poor year. The inflow of orders has declined, within turn a reduction in the output of marine equipment from our factories.

Taking all three sections together, the overall result has been a moderate fall in the total turnover of the company.

…

Southhook Potteries – You will have observed the announcement in the press of our intention to make an offer to the members of Southhook Potteries Limited, Bonnyton Works, Kilmarnock, to acquire the whole of their share capital. The Southhook Directors have recommended their shareholders to accept our offer and a copy of the letter of offer is being sent to you under separate cover for your information, together with a notice of an Extraordinary General Meeting and a Class Meeting of the Ordinary Shareholders which are needed for the purpose of consenting to the issue of Ordinary Shares as a result of the terms of the Offer. We hope to welcome Southhook to our Group and expect that our position will be strengthened by this acquisition …

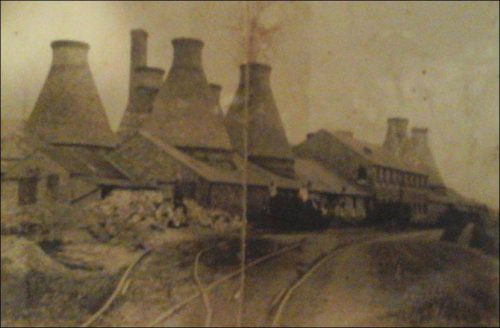

Below – Believed to be a photograph of the Southhook Brick Work and Potteries, Kilmarnock. Date unknown.

Below – The Southhook and Shawsrigg Fireclay Company Co Ltd Kilmarnock – Ashtray advertising. This ashtray is owned by Francisco Haro, Stewarton, East Ayrshire.

Below – The Scottish Industrial Archaeology Survey published a report in 1985 entitled ” A survey of Scottish brickmarks. During the compilation of this report in which the survey officers visited working and derelict brickworks sites, many items of interest were donated or found. Many of these items were thereafter donated to the National Museum Scotland. The item below is one of these items. An iron stamping plate marked ‘Southhook’.

Below – 2020 – Many thanks to Chris Hawksworth for the following photograph. Chris states – The photo shows a length of narrow-gauge railway track which still exists on the road adjacent to the fireclay works. It is roughly where the red line is on the map. I assume it was related to the fireclay works but I don’t know what it was used for. It doesn’t appear on any OS maps that I have seen. There were standard gauge sidings at the colliery, so it was most likely some sort of internal railway system.

.

Below – Unknown date – BR Steam in Scotland by George. C. O’Hara and shows a steam engine passing the Southhook Works.

Below – Unkown date – A photo from ‘Old Crosshouse’ a Stenlake publication.

Southhook Fireclay Works Ltd near Knockentiber was established in 1904, making glazed and fired bricks. In 1910 the company expanded into Bonnyton, opening up new works – seen in this photograph – that were responsible for producing sanitary ware such as sinks, toilets and mortuary tables. Expanding again in 1928 they opened another establishment in Shawrigg near Larkhall, to produce sanitation pipes, vents, troughs and chimney cans. The Shawrigg factory only lasted a few years before it closed down. Over this period the company name changed to Southhook Potteries Ltd. Southhook Fireclay Works also erected homes for its workers, naming them Southhook Row. Later there was another row of this name and to distinguish between the two, the original row became known as the ‘old’ row. This row was owned by Mrs Eliza Wilson, wife of James Wilson, who was one of the company directors. Mrs Wilson came from a well-established carpet manufacturing family in Kilmarnock who were very civic-minded and produced a magistrate for the town from 3 consecutive generations, including Hugh, James’ father. The chairman and managing director of Southhook in 1914 was Mr Gavin Anderson, a former lawyer in Kilmarnock. The firm was purchased in 1963 by Shanks and the last sanitary ware factories in Ayrshire closed on 03/07/1981.