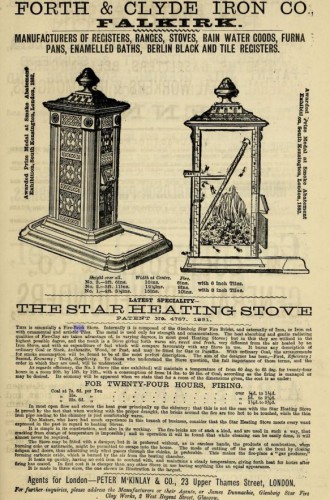

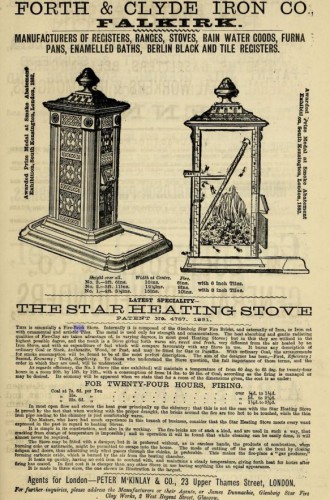

Forth & Clyde Iron Company, Falkirk. Manufacturers of registers, rangers, stoves, rainwater goods, furna pans, enamelled baths, Berlin black and tile registers. Latest speciality – The start heating stove. Patent No 4787 – 1881.

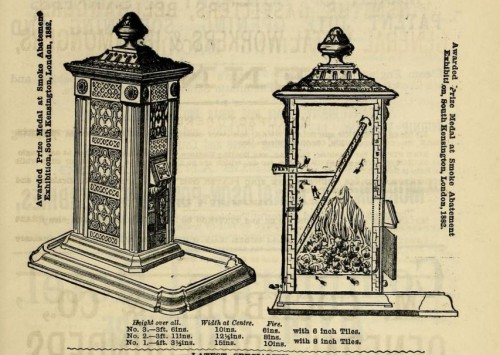

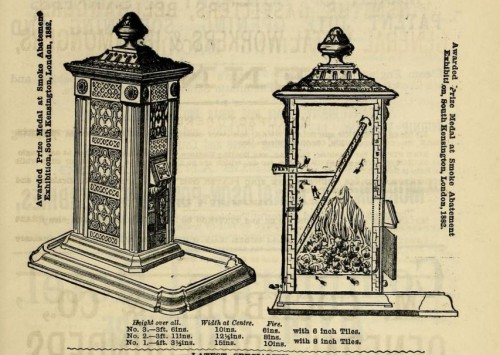

This is essentially a Fire-Brick Store. Internally it is composed of the Glenboig Star Fire Bricks, and externally of Iron, or Iron set with ornamental and artistic Tiles. The metal is used only for strength and ornamentation. The heat-absorbing and gentle radiating qualities of Fire-Clay are taken advantage of, in varying degrees, in most good Heating Stoves; but in this they are utilised in the highest possible degree, and the result is a Stove giving forth warm air, sweet and fresh, very different from the air heated by an Iron Stove, and with an expenditure of fuel which will compare favourably with any Stove in use. It burns any description of ordinary Coal or Slack, Anthracite, Wood, or Peat, and may be fitted for Gas or Paraffin. With ordinary Coal, the arrangements for smoke consumption will be found to be of the most perfect description. The aim of the designer has been.-First, Efficiency; Second, Economy; Third, Simplicity. To those who understand the Stove question, the full importance of these terms, and the order in which they are used will be understood.

As regards efficiency, the No. 1 Stove (the size exhibited) will maintain a temperature of fro 60 deg. To 65 deg. For twenty-four hours in a room 20ft. by 15ft. by 12ft., with a consumption of from 14 lbs. to 28lbs. of Coal, according as the firing is managed or as may be desired. Its economy will be apparent when we state that for a room of the dimensions given, the cost is as under:

For twenty-four hours firing

Coal at 7s. 6d. per Ten . . . . . . . . . . . over ½ d. to 1 ½ d.

“ 15s. “ . . . . . . . . . . . “ 1d. to 2 ¼ d.

“ 22s. 6d. “ . . . . . . . . . . . “ 1 ½ d. to 3 3/8 d.

In most open fired and stoves the heat goes principally up the chimney; that this is not the case with the Star Heating Stove is proved by the fact that when working with the proper draught, the bricks around the fire are too hot to be touched, while the thin iron pipe leading to the chimney is just comfortably warm.

The Makers, who have had much experience in this branch of business, consider that the Star Heating Stove meets every want expressed in the past in regard to heating Stoves.

It is simple in its construction, and also in its working. The fire-bricks are of such a kind, and are used in such a way, that cracking from the change of temperatures is impossible; and in operation, it will be found that while cleaning can be easily done, it will almost never be required.

The Stove may be fitted with a damper, but it is preferred without, as in careless hands, the products of combustion, when burning coke or anthracite, might be permitted to escape into the house. The mode of cutting off the air at the front by clawing ash-pan and doors, thus admitting only what passes through the chinks, is preferable. This makes the fire-place a “gas producer,” forming carbonic oxide, which is burned by the air from the heating chamber.

It heats up quickly, having no cold iron to contend with, and maintains a steady temperature, giving forth heat for hours after firing has ceased. In first cost, it is cheaper

than any other Stove in use having anything like an equal appearance. It is made in three sizes, the one shown in Illustration is the largest.

Agents for London – Peter McKinlay & Co, 23 Upper Thames Street, London.

For further inquires, please address the Manufacturers or their Agents, or James Dunnachie, Glenboig Star Fire Clay Works, 2 West Regent Street, Glasgow.

Below – 1882 – Forth & Clyde Iron Co and the ‘Star Heating Stove’

.

01/01/1882 – The Journal of domestic appliances and sewing machine gazette.

Mr James Dunnachie, Glenboig, Cambridge (Coatbridge?!) – The Star Heating Stove is shown by this exhibitor. It is made of fine clay with iron exterior and is suitable for coal, gas, oil or wood.

20/08/1890 – The manufacturer and inventor … Nor has the fertile and inventive brain of the talented managing director (James Dunnachie) been idle in other departments of the Glenboig Works. He has been devoting his life to the advancement of the company with which he is so closely identified, and we cannot do better than make a brief reference to Dunnachie’s patent drying stove. To prevent the overheating of the end nearest to the fires, two floors are employed, the lower one composed of fire clay covers running halfway up the stove from the firing end, and the upper, consisting of iron plates, running the whole length of the stove and forming the real floor. The space between forms an air flue, communicating with the open air at the gable over the fires, and with the flue at the middle of the stove. This stove dries every brick every day with perfect regularity and freedom from cracking. It permits of two moulders working on the space usually allotted to one. The same gentleman’s ” Star” heating stove was awarded a prize medal at the South Kensington Smoke Abatement Exhibition, 1882. It is essentially a fire brick stove. Internally it is composed of the Glenboig fire-bricks, and externally of iron, or iron set with ornamental and artistic tiles. The metal is used only for strength and ornamentation. The heat-absorbing and gentle radiating qualities of fire-clay are taken advantage of, in varying degrees, in most good heating stoves; but in this they are utilised in the highest possible degree, and the result is, a stove giving forth warm air, sweet and fresh, very different from the air heated by an iron stove, and with an expenditure of fuel which will compare favourably with any stove in use. It burns any description of ordinary coal or slack, anthracite, wood, or peat, and may be fitted for gas or paraffin. With ordinary coal, the arrangements for smoke consumption will be found to be of the most perfect description. The aim of the designer has been efficiency, economy and simplicity. To those who understand the stove question, the full importance of these terms, and the order in which they are used will be understood. It is simple in its construction, and also in its working. The fire-bricks are of such a kind, and are used in such a way, that cracking from the change of temperature is impossible; and in operation, it will be found that while cleaning can be easily done, it will almost never be required. The mode of cutting off the air at the front by closing ashpan and door, thus admitting only what passes through the chinks, if preferable. This makes the fire-place a “gas producer,” forming carbonic oxide which is burned by the air from the heat ing chamber. It heats up quickly, having no cold to contend with, and maintains a steady temperature, giving forth heat for hours after firing has ceased. In first cost it is cheaper than any other stove in use, having anything like an equal appearance. It is made in three sizes and is suitable for heating churches, schools, halls, offices, vineries, &c. Referring to the engravings on page 332, Fig. 1 illustrates the Old Works, and Fig. 2 the Star Works, both at Glenboig, and Fig. 3 the Cumbernauld Works.